Feeding device for circulation sewing machine

A feeding device and sewing machine technology, applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve problems such as troublesome operation, waste of time, and inability to ensure stable stitch distance, etc., and achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

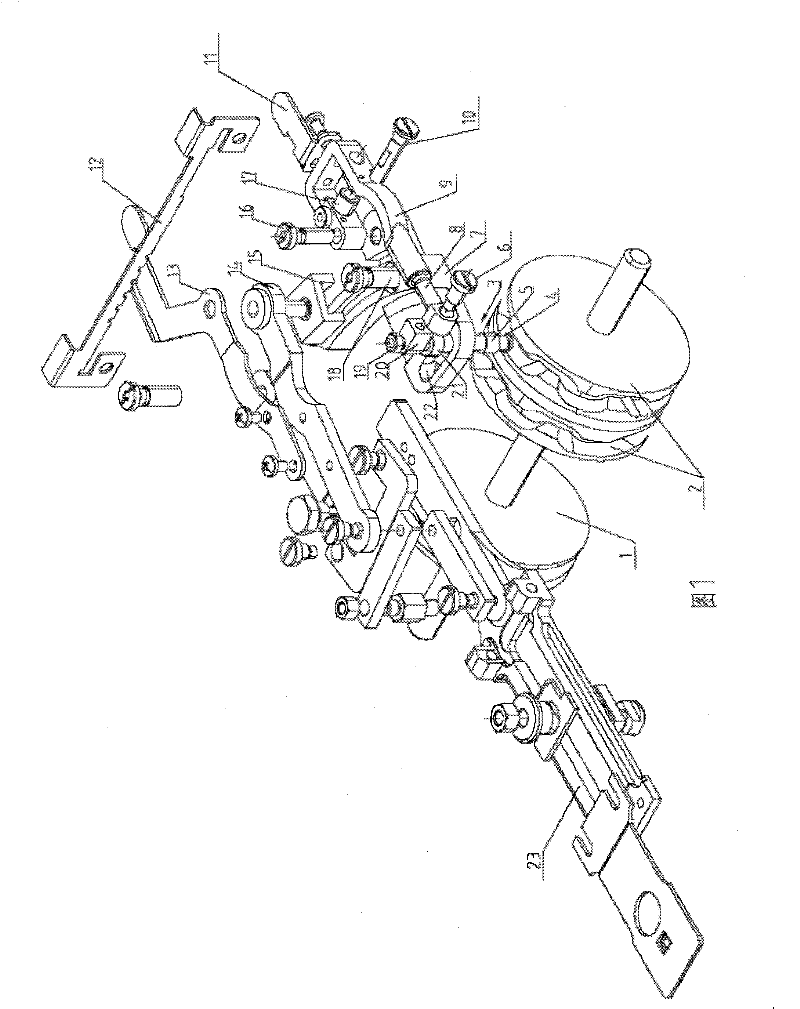

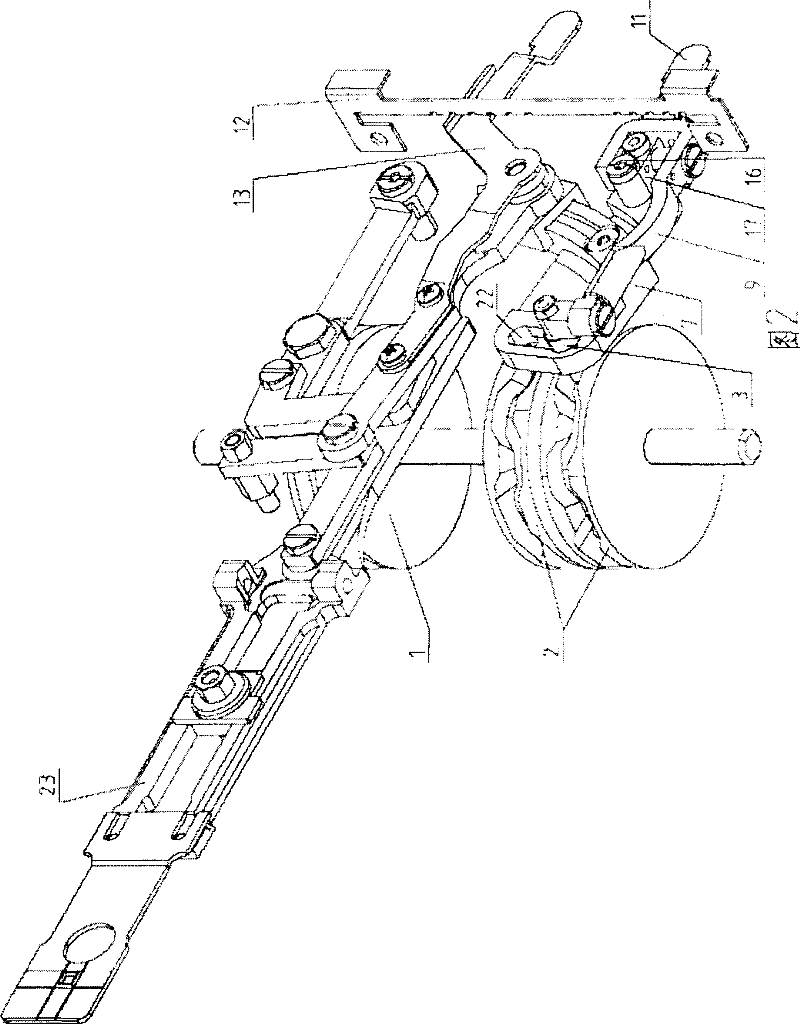

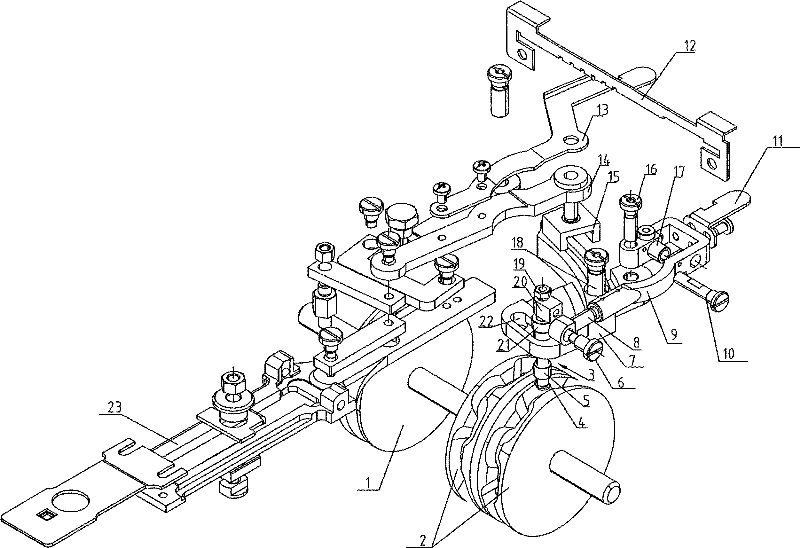

[0014] The specific embodiment of the present invention is described below: a feeding device of a circular sewing machine, including a front and rear feeding cam 2 for making the feeding table 23 move toward the front and rear directions and a left and right feeding cam 2 for making the feeding table 23 move toward the left and right directions. The feed cam 1, the front and rear feed cam 2 are composed of two cam parts arranged on the same axis, and each cam part corresponds to a different pattern of the feeding table 23. The left-right direction and the front-rear direction are relative directions defined artificially, so the left-right and front-rear directions in the present invention cannot be defined relative to the workbench of the sewing machine.

[0015] The feeding device also includes a feeding swing bar 7, a front and rear feeding adjustment table 14 and a front and rear feeding shaft slide block 15 arranged between the described feeding swing bar 7 and the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com