Roofing board connecting structure

A technology for connecting structures and roof slabs, which is applied to roofs, building structures, roof coverings, etc., and can solve problems such as difficulty in fixing the lower end of roof slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred modes for carrying out the present invention will be described below.

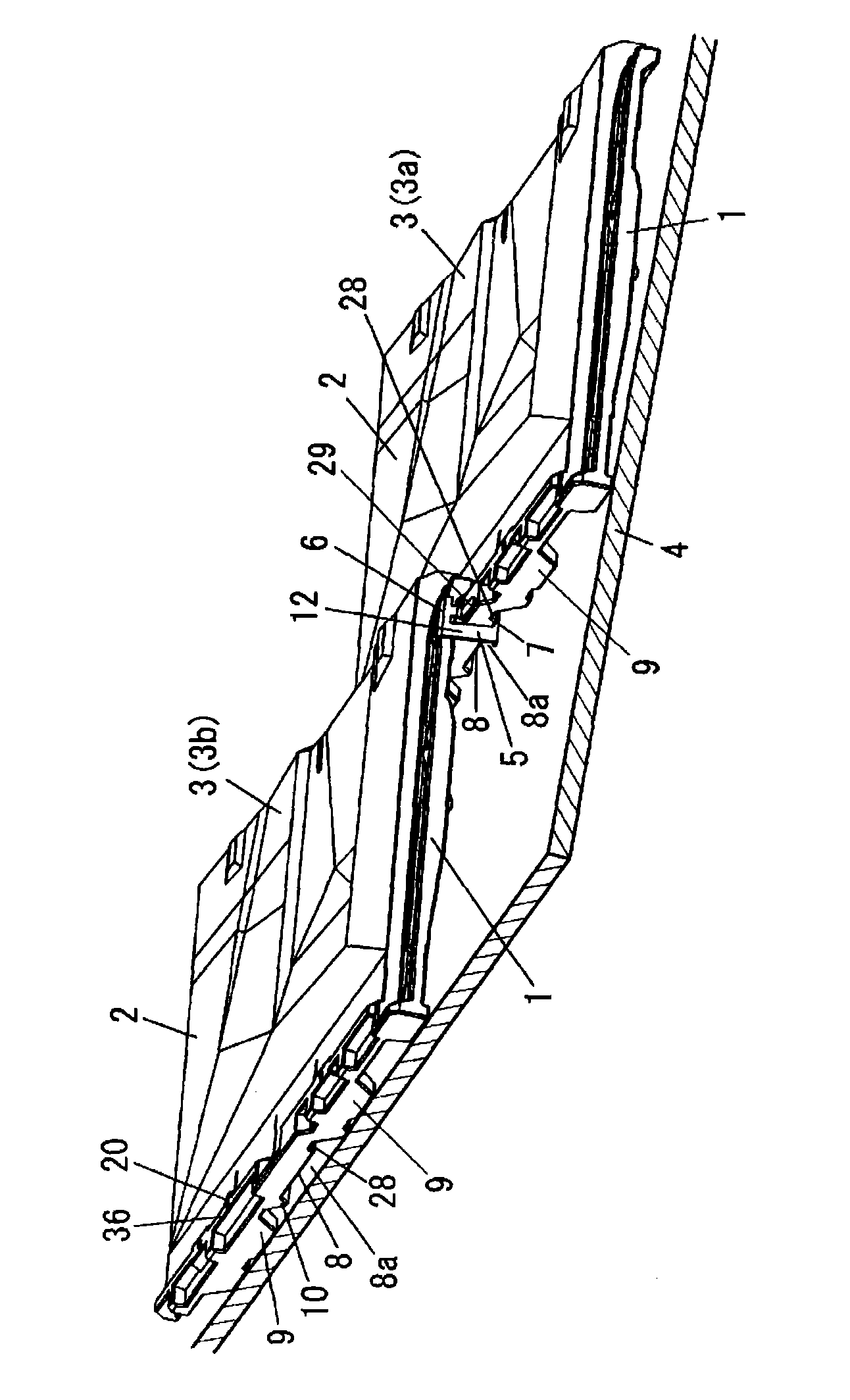

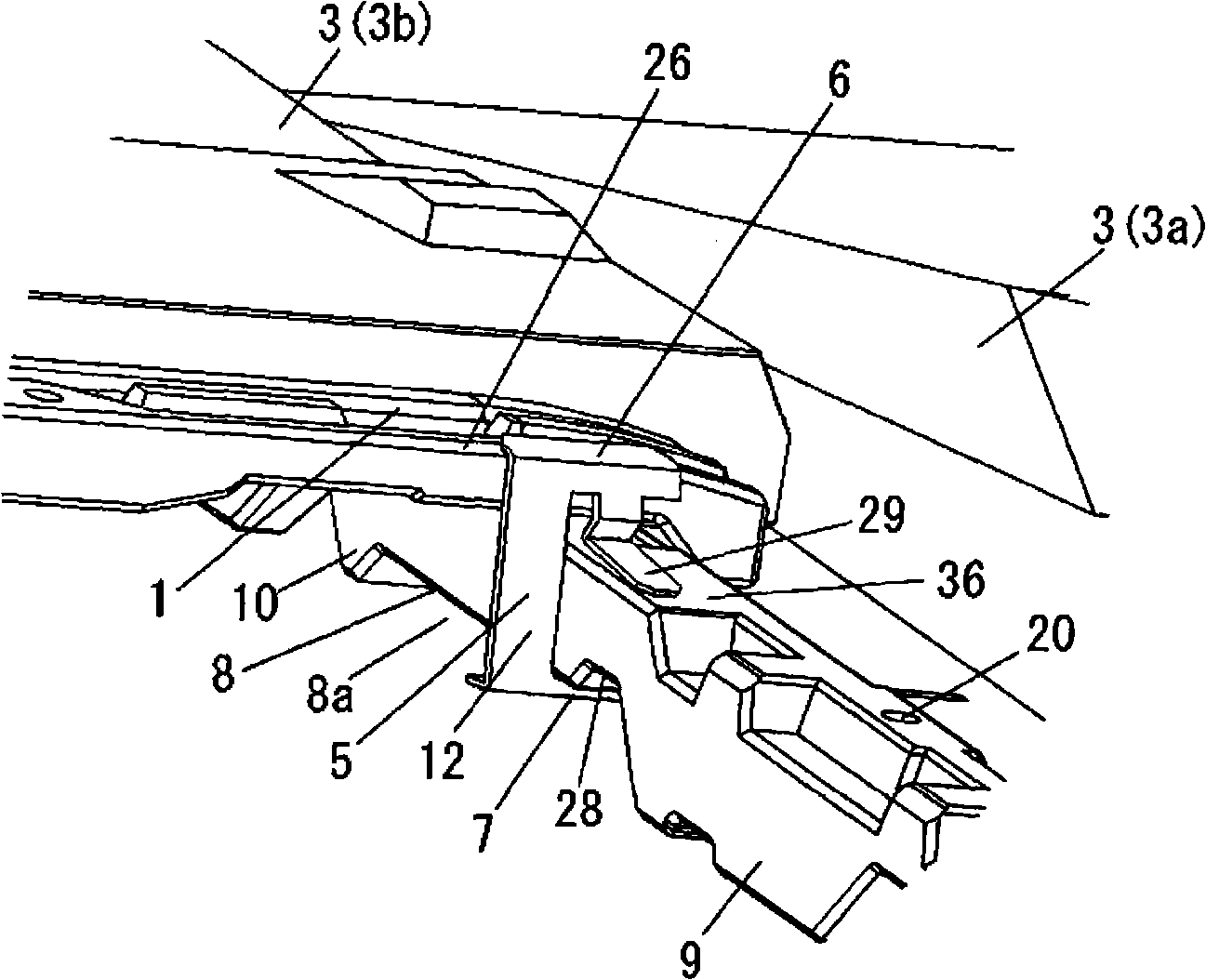

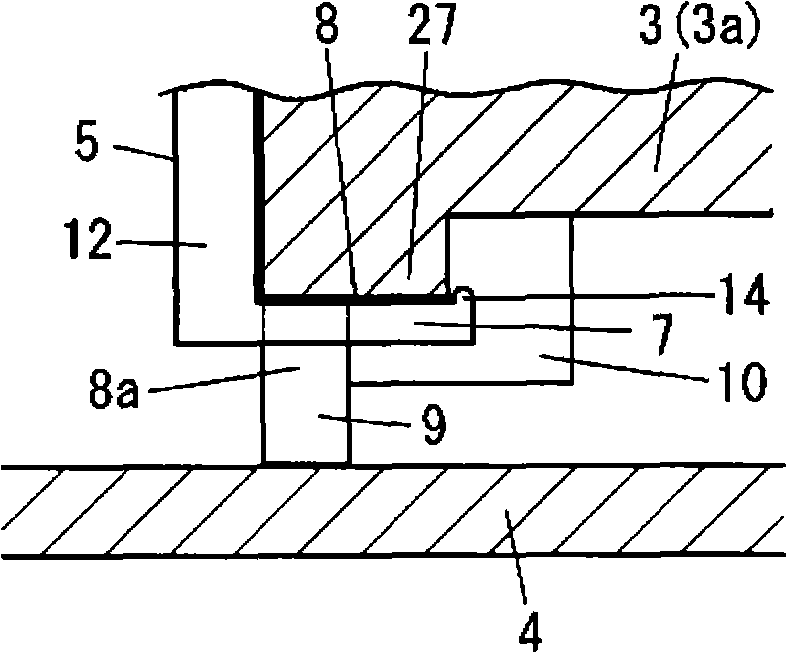

[0035] Figure 3A It is a top view showing the roof panel 3 used in this embodiment. Figure 3B It is a perspective view showing the lower surface of the roof panel 3 used in this embodiment. exist Figure 3A In , the X direction represents the front of the roof slab, and the Y direction represents the right of the roof slab. Similarly, in Figure 3B In , the X direction represents the front of the roof slab, and the Y direction represents the right of the roof slab. The roof panel 3 is manufactured by firing mineral raw materials such as clay in a furnace. A plurality of roof panels 3 are arranged up, down, left, and right on the roof base, and the roof base is arranged between the ridge and the eaves. Here, the ridge is the horizontal building material used at the top of the roof frame. Also, the eaves are the parts that protrude from the outer walls of the building at the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com