Novel integrated type connector press-fix structure

An integrated connector technology, which is applied to parts, connections, electrical components, etc. of the connection device, can solve problems such as inconvenient crimping, difficult gaskets, and inconvenient press-fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the drawings and specific embodiments.

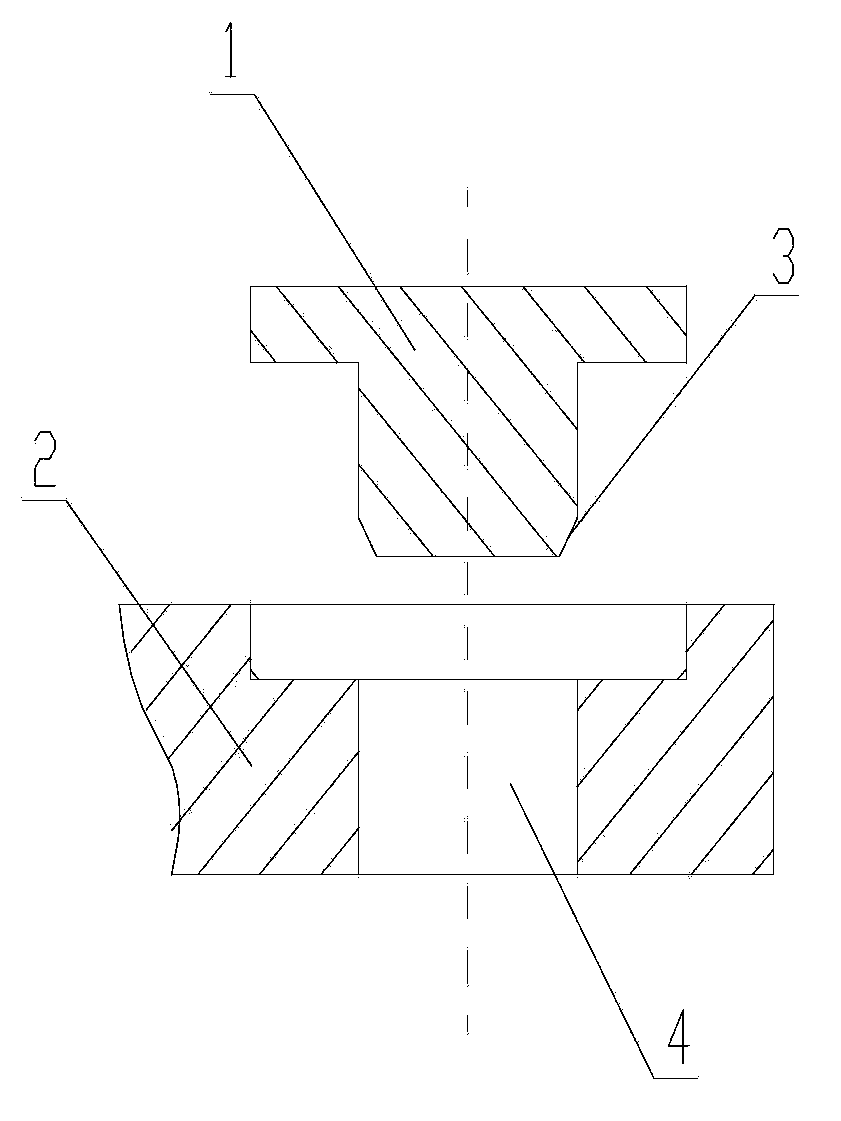

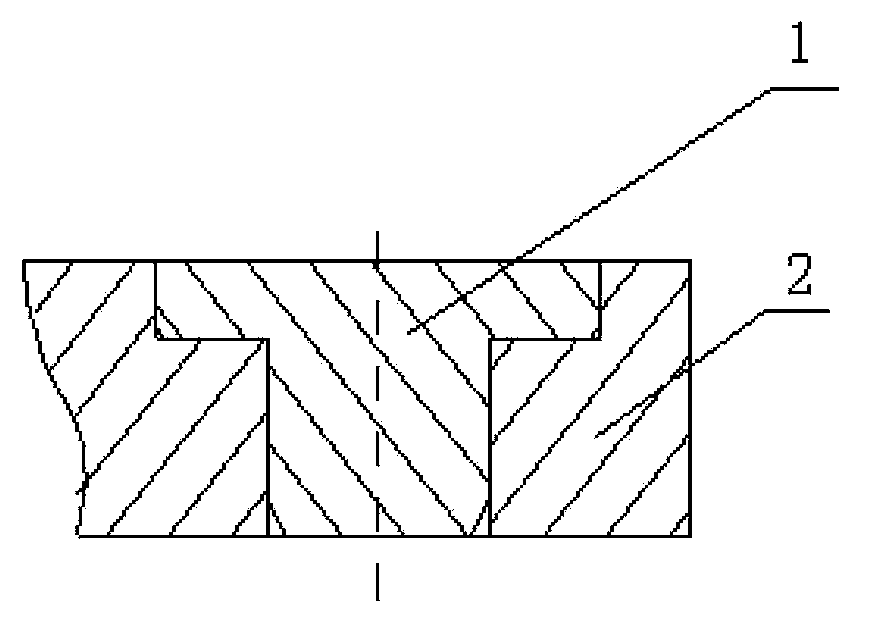

[0014] Such as figure 1 As shown, a new type of integrated connector press-fit structure of the present invention includes a gasket 1 and a housing 2. A gasket press-in hole 4 that matches the shape of the gasket 1 is opened in the housing 2 and is characterized by : A chamfer 3 is provided around the bottom of the gasket 1 pressed into the housing 2. The shape of the gasket 1 in this embodiment is T-shaped, and the shape of the gasket press-in hole 4 is also a T-shaped matching the gasket.

[0015] Preferably, the chamfer 3 is 30°.

[0016] Preferably, the gasket 1 and the casing 2 are both rigid elements, and the hardness of the T-shaped gasket 1 is greater than the hardness of the casing 2.

[0017] The described a new type of integrated connector press-fit structure, wherein the processed gasket 1 can be simply processed by a CNC lathe such as figure 1 The chamf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com