Absorbent article

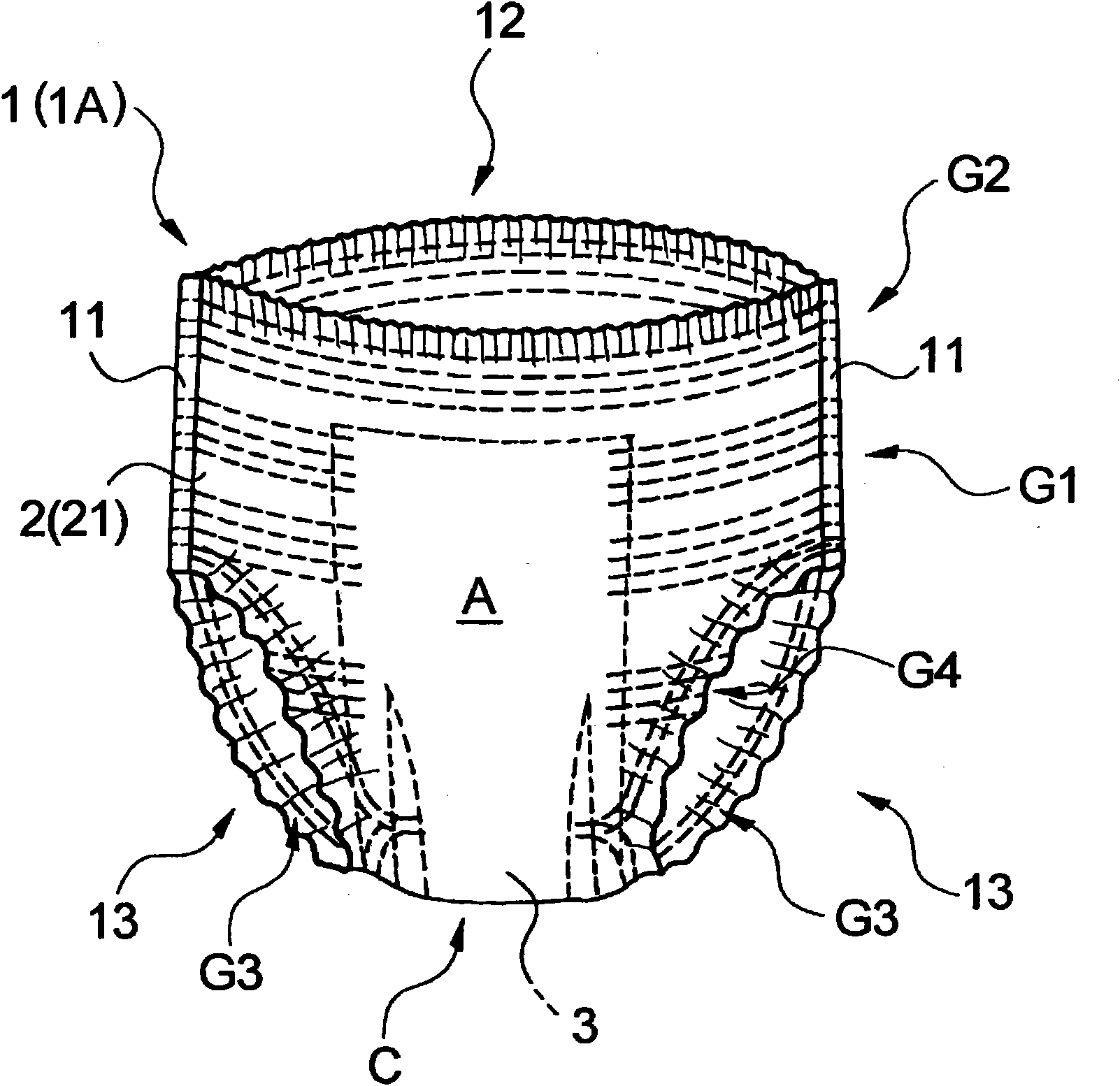

It is an absorbent and article technology, which is applied in the direction of absorbent pads, medical science, clothing, etc., and can solve the problems of elastic member shrinkage resistance, poor cushioning, and insufficient use of elastic member shrinkage force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

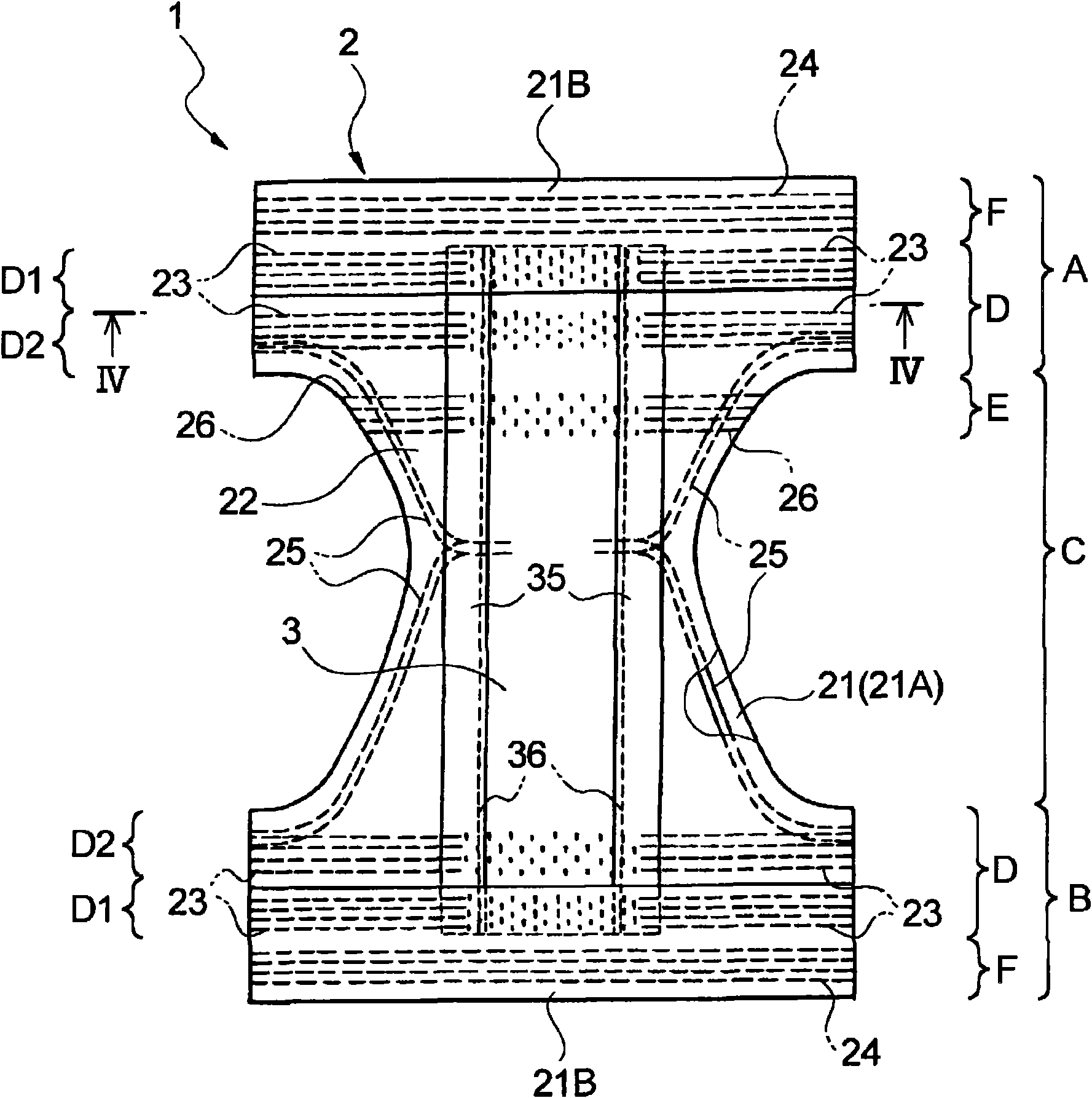

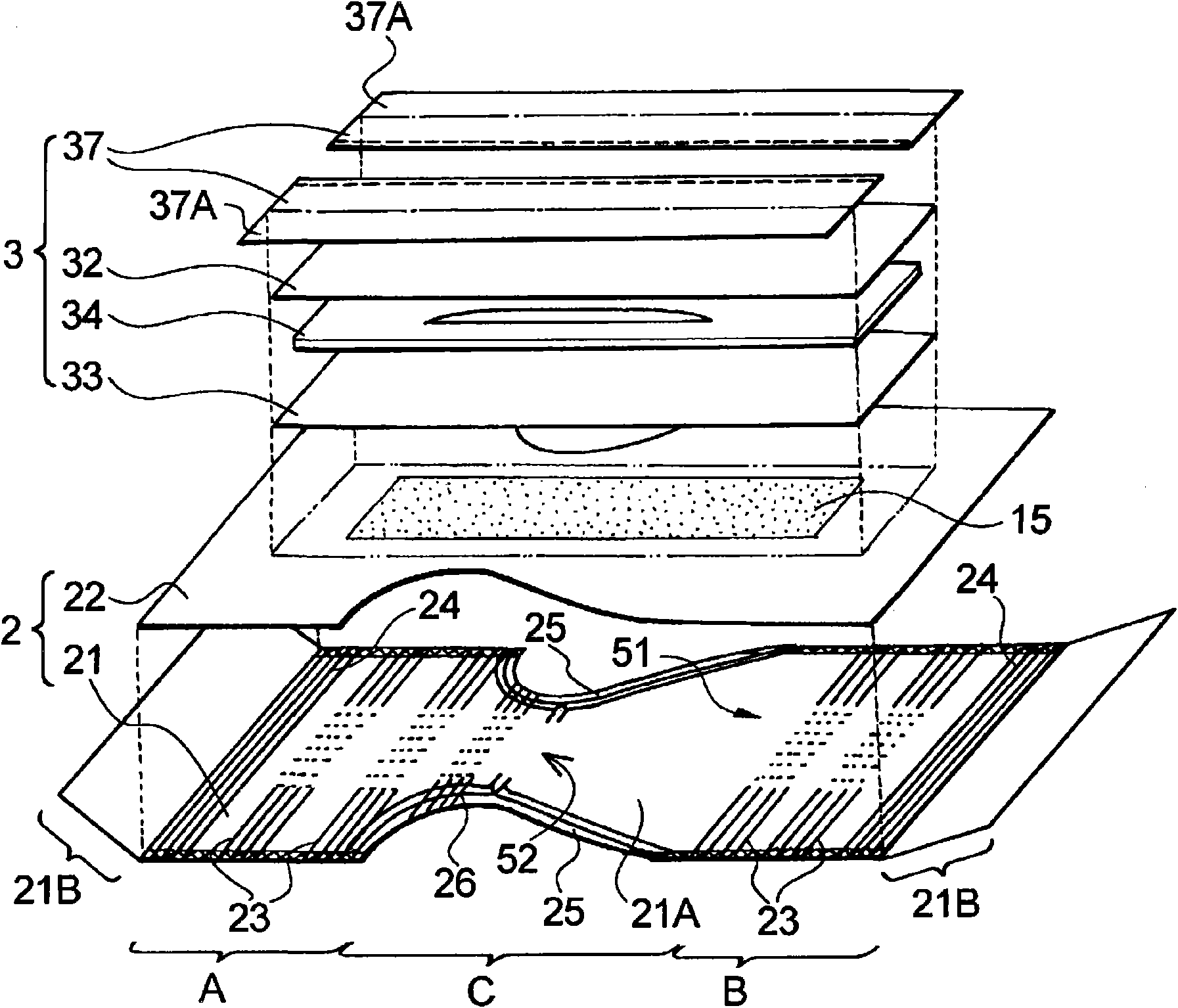

Embodiment 1

[0450] "Example 1" was prepared as an example corresponding to the above-mentioned second embodiment. Specifically, as the outer layer sheet 21 and the pressing sheet 27, a hydrophobic air-through nonwoven fabric (weight per unit area of 20 g / m 2 ) composed of a core-sheath composite fiber whose core is PET / sheath is PE is used. 2 ), as the inner layer sheet 22, use the hydrophobic spun-bonded non-woven fabric (weight per unit area is 16g / m 2 ). As the hydrophilic sheet 29 separated from the inner layer sheet 22, a non-woven fabric (weight per unit area of 10 g / m2) that has been hydrophilized to the SMMS non-woven fabric composed of PP fibers is used. 2 ).

[0451] In Example 1, the outer layer sheet 21 and the inner layer sheet 22 are joined to each other by intermittent joining portions 41 in the stretching direction of the composite stretchable portion 4 and in a direction perpendicular to the stretching direction. The hydrophilic sheet 29 is disposed on a region cor...

Embodiment 2

[0453] "Example 2" was prepared as an example corresponding to the above-mentioned fifth embodiment. Specifically, as the outer layer sheet 21 and the pressing sheet 27, the same nonwoven fabric as that of the outer layer sheet 21 in Example 1 was used. On the other hand, unlike Example 1, the hydrophilic sheet 29 separate from the inner layer sheet 22 is not provided. That is, the entire inner layer sheet 22 is the hydrophilic sheet 29 , and the same nonwoven fabric as the hydrophilic sheet 29 in Example 1 is used as the hydrophilic sheet 29 . Other than that, it is the same as in Example 1.

Embodiment 3

[0455] As a partly different example from Example 1, "Example 3" was created. Embodiment 3 Compared with Embodiment 1, the hydrophilic sheet 29 uses a spunlace nonwoven fabric (weight per unit area is 40 g / m2) made of rayon (70% by weight) and PET (30% by weight). 2 ). Other than that, it is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com