Uneven surface bonding method of artificial skin and hard material as well as product thereof

A technology for artificial leather and articles, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem that artificial leather cannot fit and fit notebook computer casings tightly, and natural leather is expensive and difficult. It presents problems such as natural leather three-dimensional lines, achieves excellent reflective effects, improves personal safety effects, and enhances the effects of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to obtain a further understanding and recognition of the features, functions and purposes of the present invention, preferred and feasible specific embodiments are exemplified and described below with accompanying drawings.

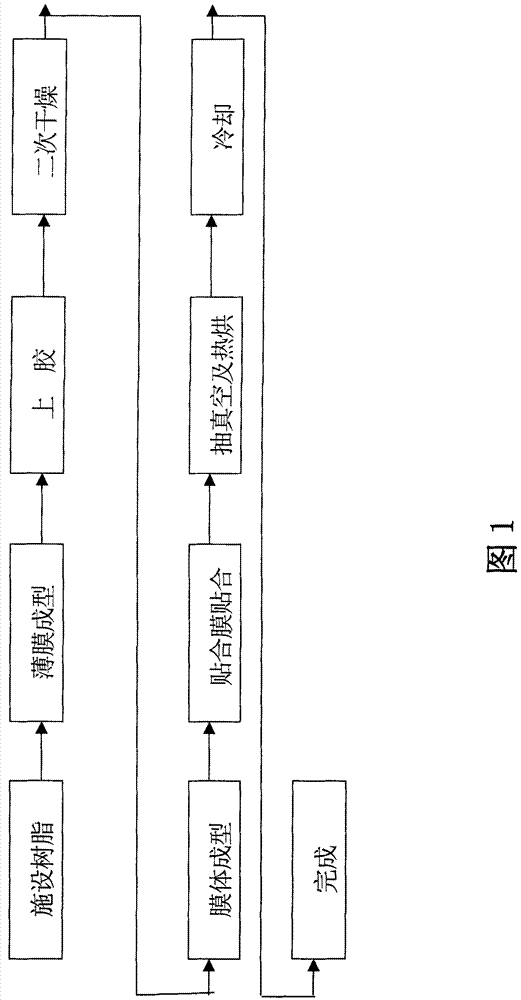

[0038] see figure 1 First of all, for the steps of the method for combining the artificial skin film with "imitation leather texture" and the non-completely flat coated surface of the hard object, a preferred embodiment is listed. figure 1 The schematic diagram of the box illustrates:

[0039] The relevant artificial skin film manufacturing process and the detailed technical means combined with the coated surface of the article revealed by the diagram include:

[0040] Application of resin: Take a film with concave-convex imitation leather texture as a release paper, and apply a latex-like plastic resin on the surface of the release paper or by coating. The plastic resin can be selected from elastic materials, such as: TPE (thermoplastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com