Steel plate excellent in toughness of large heat-input weld heat affected zone

A technology of welding heat impact and high heat energy, which is applied in the field of steel with improved toughness, can solve the problems of low desulfurization ability and high S content, and achieve the effect of improving HAZ toughness and excellent HAZ toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

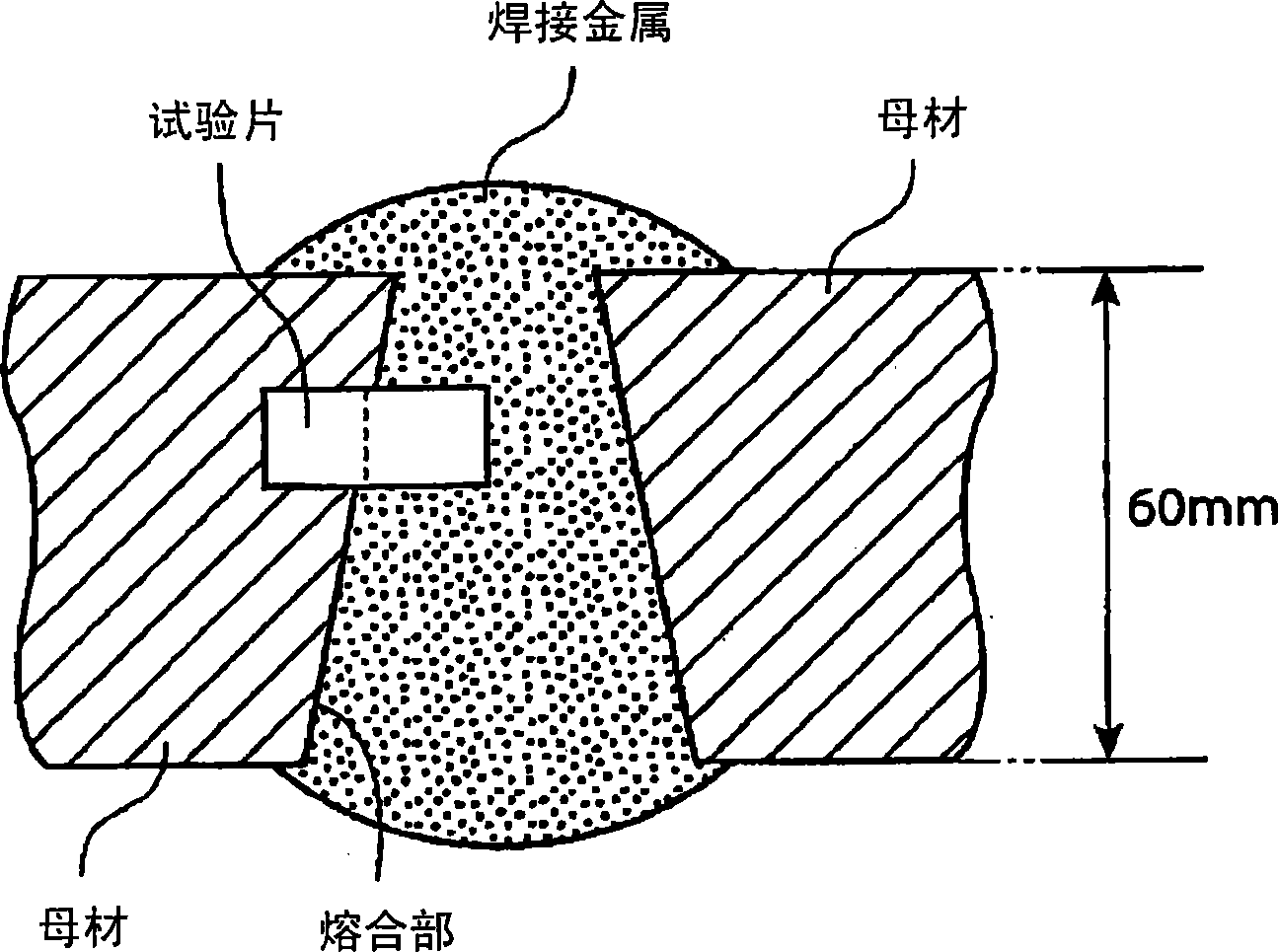

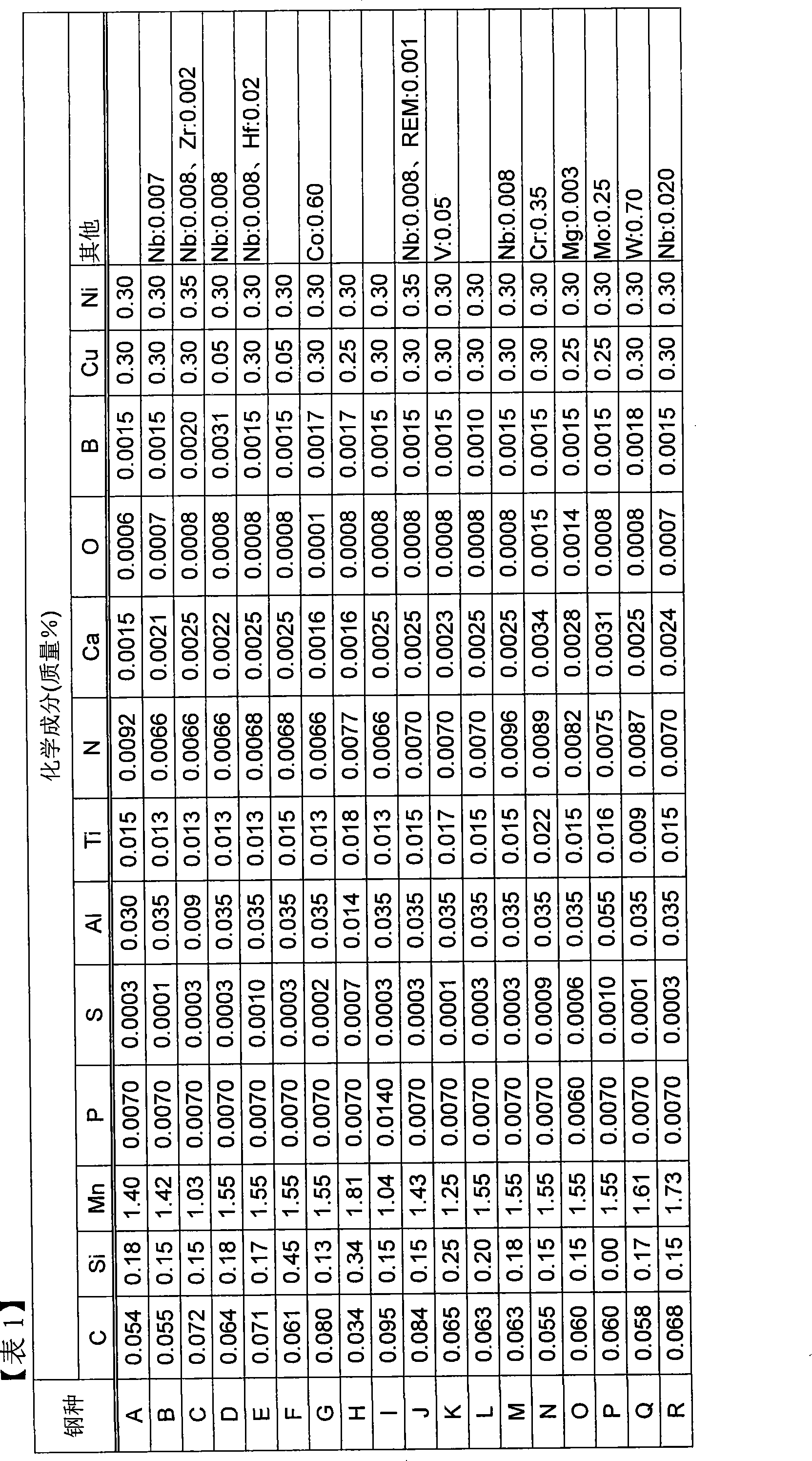

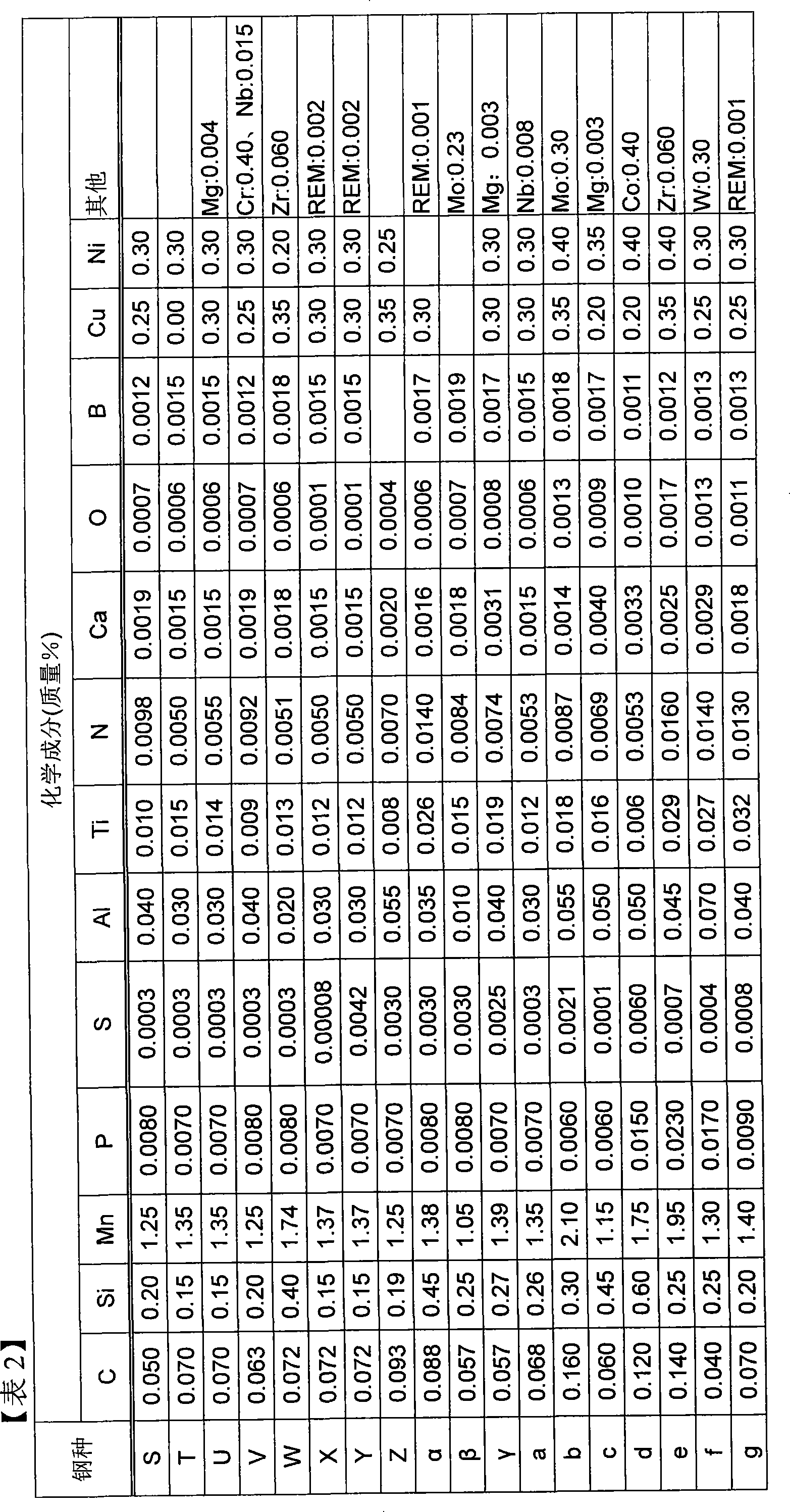

[0094] Melt steel with the composition shown in Table 1 or Table 2 below by a normal melting method (the balance is iron and unavoidable impurities), cast the molten steel to form a slab, and heat the slab to the temperature shown in Table 3 or Table 2. The temperature (measured value) shown in Table 4 is then hot-rolled to become a hot-rolled sheet with a thickness of 60mm. After the hot-rolling is completed, it is water-cooled and quenched to produce a tensile strength of 490-780MPa (50-80kg / mm 2 Grade) of various high-tensile steel plates (test panels). Also, in the steelmaking stage, the deoxidation time is 30 minutes.

[0095] In Table 1 and Table 2 below, REM is added in the form of misch metal containing about 50% of La and about 25% of Ce.

[0096] The heating temperature of the slab is controlled in consideration of the slab heating temperature (calculated value) calculated by Thermo-calc in relation to the amount of solid solution N as described above.

[0097] In ...

Embodiment 2

[0114] The HAZ toughness when the welding conditions were changed was evaluated for the steel sheet shown in Example 1 above.

[0115] Plates with a thickness of 25 mm were cut from various high-tensile steel plates (60 mm thick) obtained in Example 1 above, and the heat input was 15 kJ / mm, and gas-electric welding was performed to produce welded joints.

[0116] The other welding conditions are the same as in the above-mentioned Example 1.

[0117] On the obtained welded portion, the V-notch pendulum impact value (vE -55 ), to evaluate the HAZ toughness. The measurement results are collectively shown in Table 3 or Table 4 below. At this time, the V-notch pendulum impact value (vE -55 ) is more than 100J as qualified.

[0118] The steel materials (No. 1 to 29) of the present invention were welded at a heat input of 15 kJ / mm, and the HAZ toughness was still good. Therefore, the steel plates (No.1-29) of the present invention, no matter whether the high heat energy input we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com