Steel material having superior toughness of welded heat-affected zone, and method for manufacturing same

A technology for welding heat impact and steel, applied in the field of steel, can solve the problem of easy deterioration of toughness, and achieve the effect of improving the toughness of HAZ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

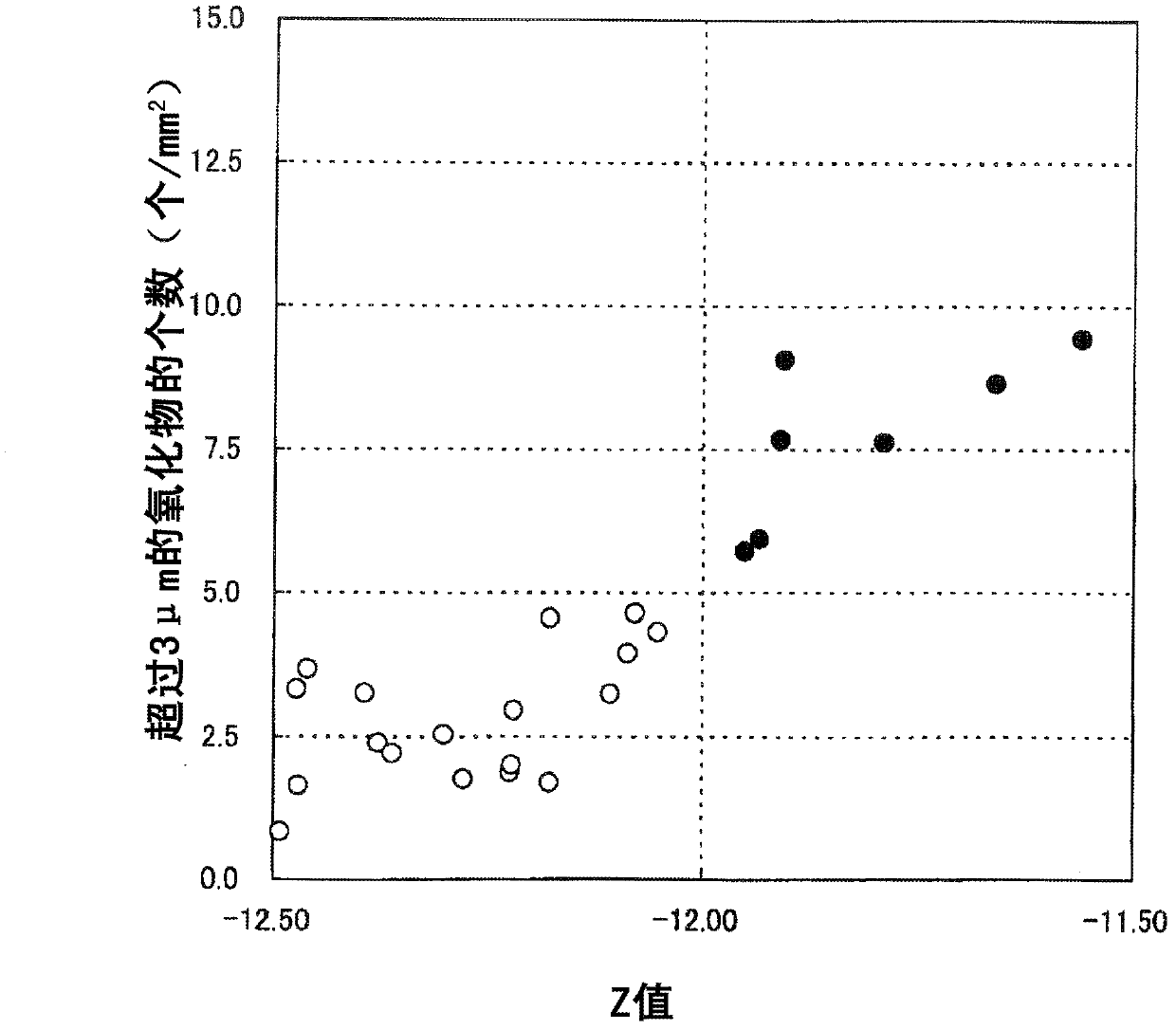

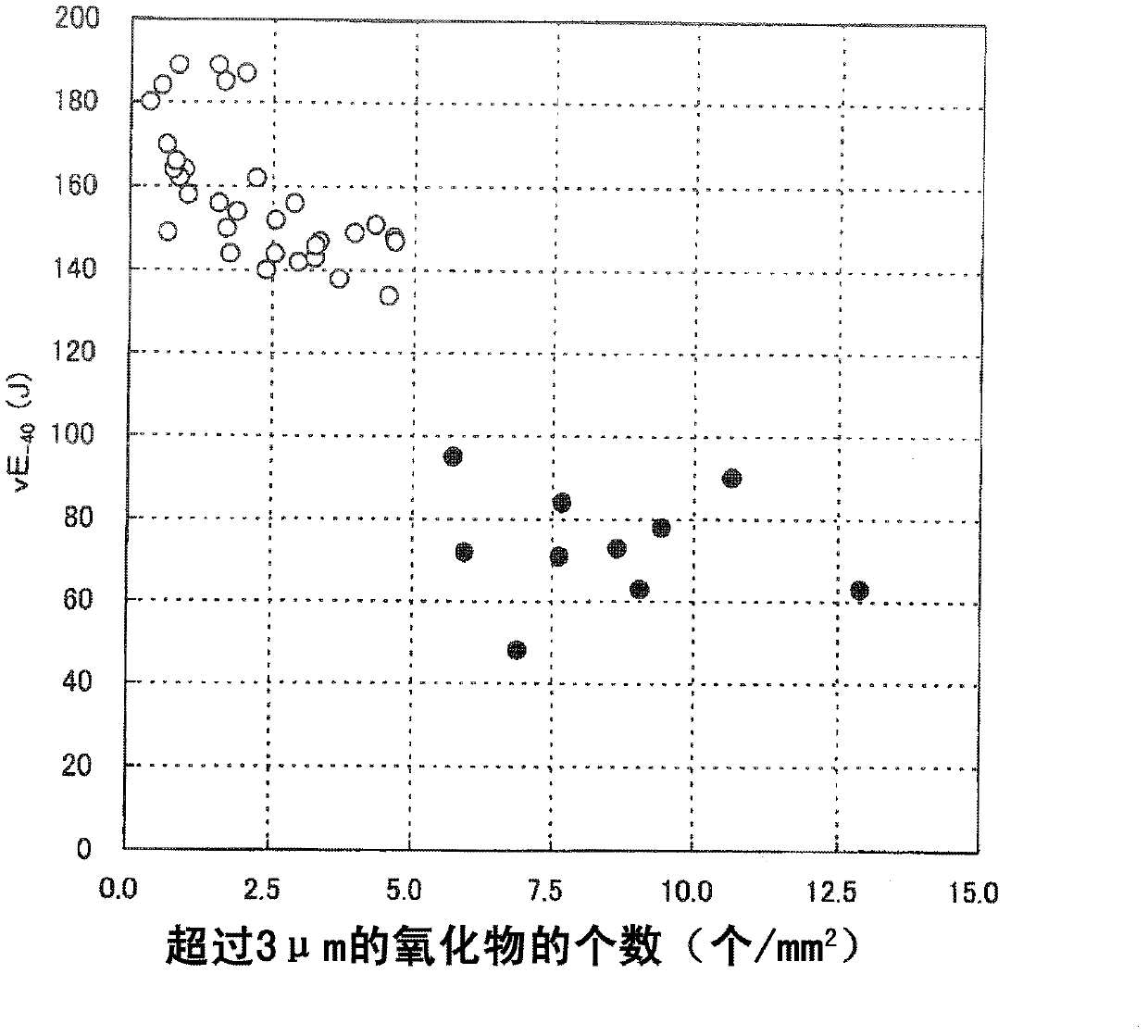

[0059] The present invention improves the technique of using the oxides that serve as nuclei for intragranular α transformation disclosed in the above-mentioned Patent Documents 1 to 4, and provides a method for obtaining welding without deterioration of HAZ toughness even with a larger heat input amount. steel technology.

[0060] That is, after the present inventor proposed the above-mentioned Patent Document 4, he conducted research in order to provide a steel material superior in HAZ toughness at the time of higher-grade high-heat-input welding. As a result, it was found that in order to provide a heat input even under the conditions of giving a larger heat input than Patent Document 4, that is, "after holding at a heating temperature of 1450° C. for 5 seconds, cooling at a temperature of 800° C. to 500° C. for 400 seconds In the case of "cycle" (heat input conditions: 1450°C x 5 seconds, cooling time Tc = 400 seconds), the steel material with excellent HAZ toughness only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com