Thick armor plate with high tension and method for manufacturing the same

A manufacturing method and technology for thick steel plates are applied in the field of thick steel plates to achieve the effects of increasing uniform elongation, reducing fracture area and preventing fracture openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] The steel obtained by smelting in a small vacuum furnace and having the composition shown in Table 1 below (the balance is Fe and unavoidable impurities) was heated at 1100° C. for 30 minutes to form an austenite single phase, and then hot rolled. The final rolling temperature was 800°C, and the final plate thickness was 12.5 mm.

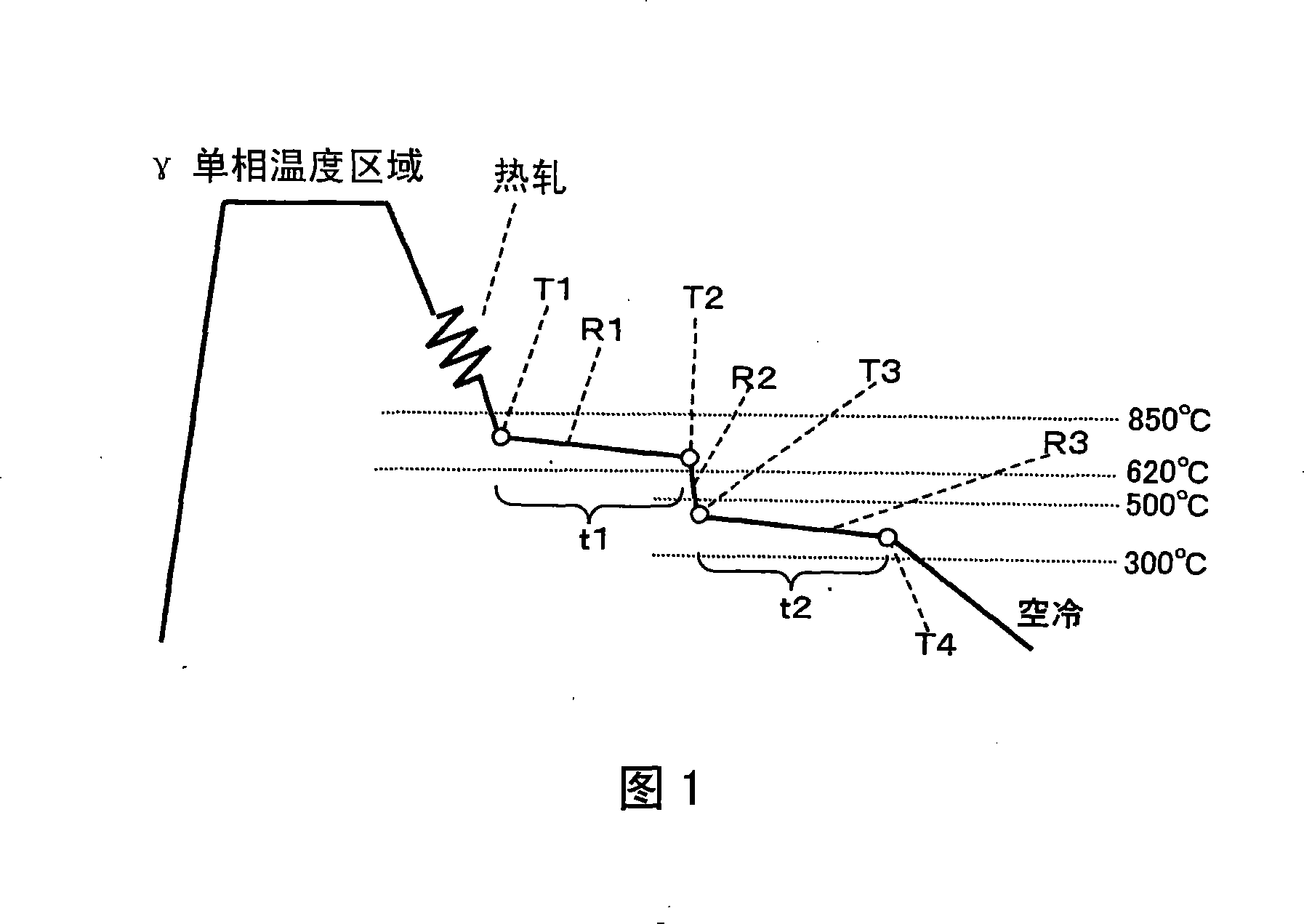

[0106] The obtained hot-rolled material was cooled under the conditions shown in Table 2 below using water cooling equipment and a heat treatment furnace. In Table 2, T1 to T4, t1 to t2, and R1 to R3 correspond to the numbers attached to the aforementioned FIG. 1 .

[0107] After cooling to the slow cooling end temperature T4, it was air-cooled to room temperature, and a thick steel plate (thickness 12.5 mm) was produced.

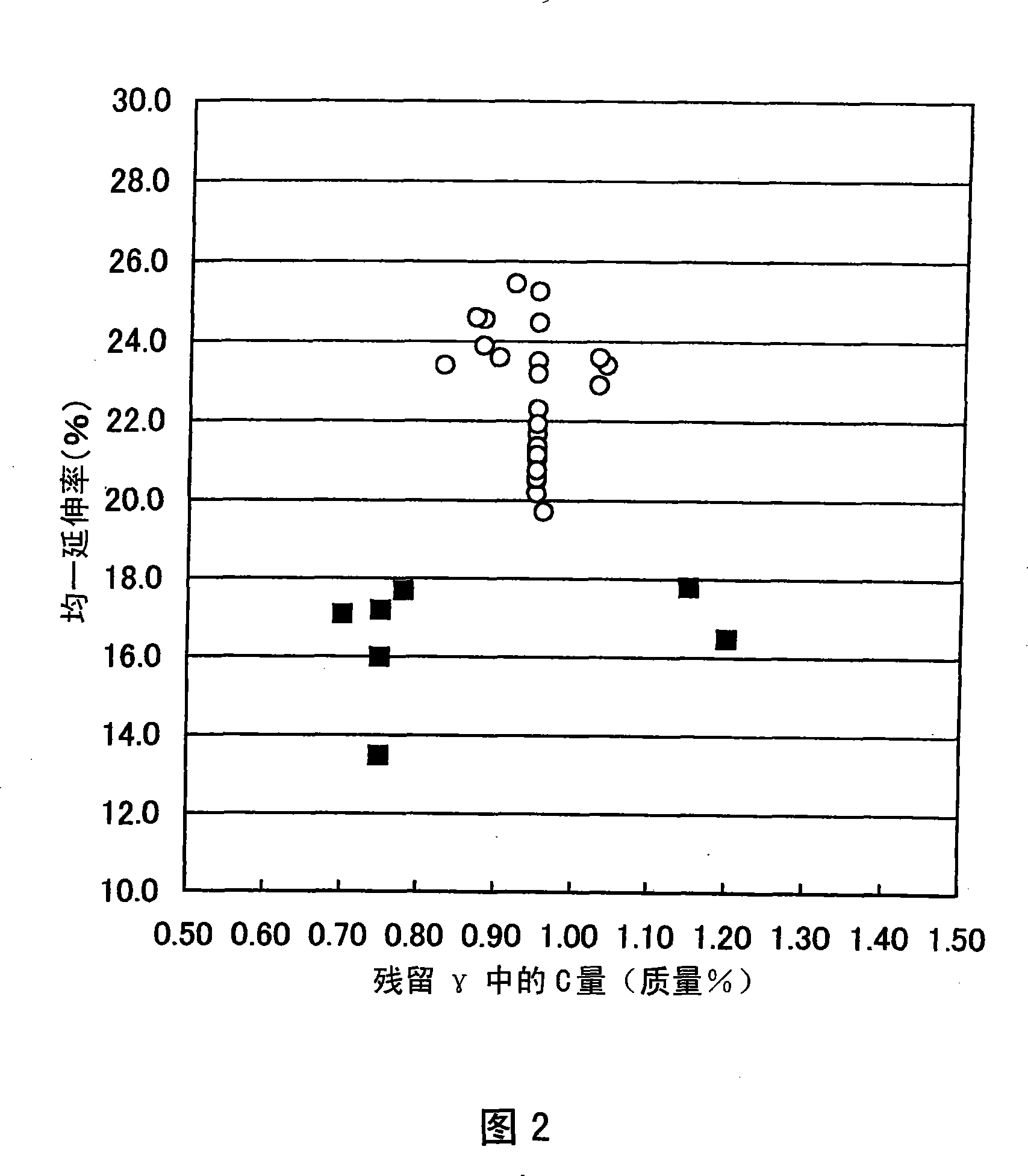

[0108] Measure the microstructure [ferrite fraction, residual γ fraction, C content in residual γ] and base metal properties [yield point (YP), tensile strength (TS)] of the obtained thick steel plate according to the fol...

Embodiment 2

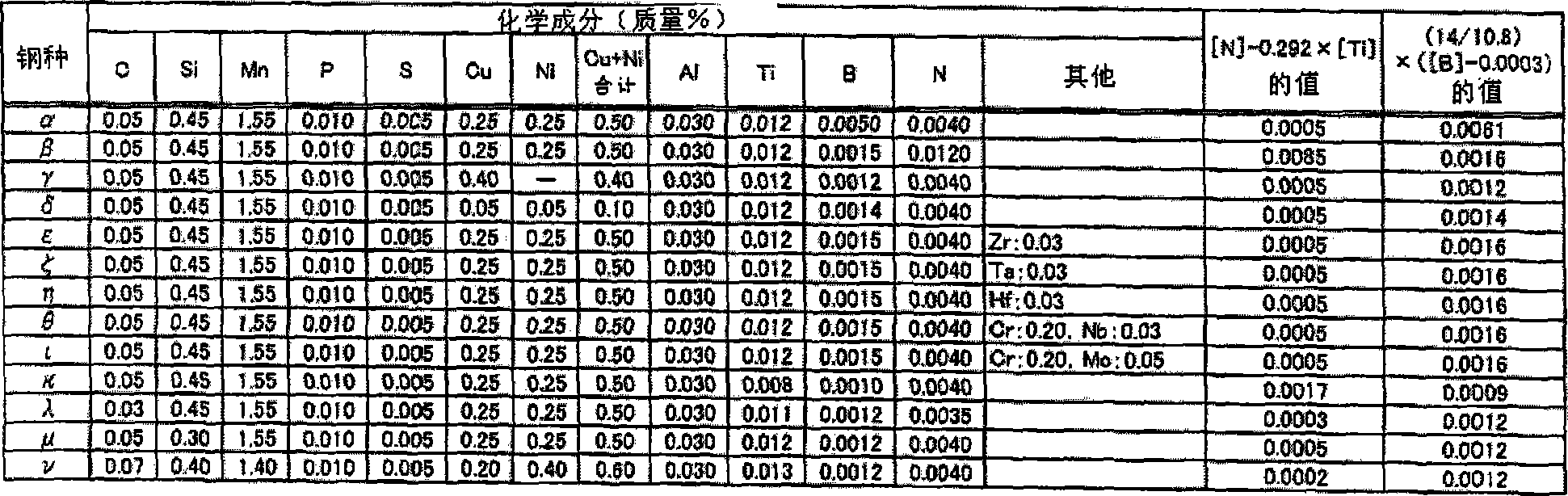

[0138] The steel obtained by smelting in a small vacuum furnace with the composition shown in the following Table 5 or Table 6 (the balance is Fe and unavoidable impurities) was heated at 1100° C. for 30 minutes to form an austenite single phase and then hot rolled. The final rolling temperature was 800°C, and the final plate thickness was 12.5 mm. In the following Table 5 or Table 6, use the following formula (1) to calculate the value of “[N]-0.292×[Ti]” according to the composition of the steel, and “(14 / 10.8)×([B]-0.0003 )" and display the value.

[0139] The obtained hot-rolled material was cooled under the conditions shown in Table 7 below using water cooling equipment and a heat treatment furnace. In Table 7, T1 to T4, t1 to t2, and R1 to R3 correspond to the numbers attached to the aforementioned FIG. 1 .

[0140] After cooling to the slow cooling end temperature T4, it was air-cooled to room temperature, and a thick steel plate (thickness 12.5 mm) was produced.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com