Steel having excellent toughness in welding heat affected zone, and manufacturing method thereof

A technology of welding heat influence and manufacturing method, which is applied in the field of steel, can solve problems such as toughness and easy deterioration, and achieve the effect of improving HAZ toughness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

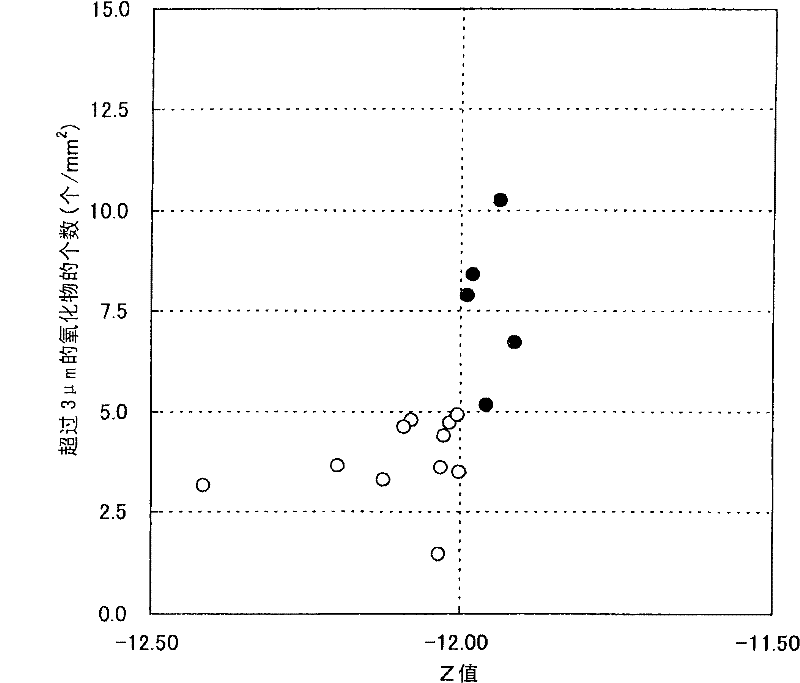

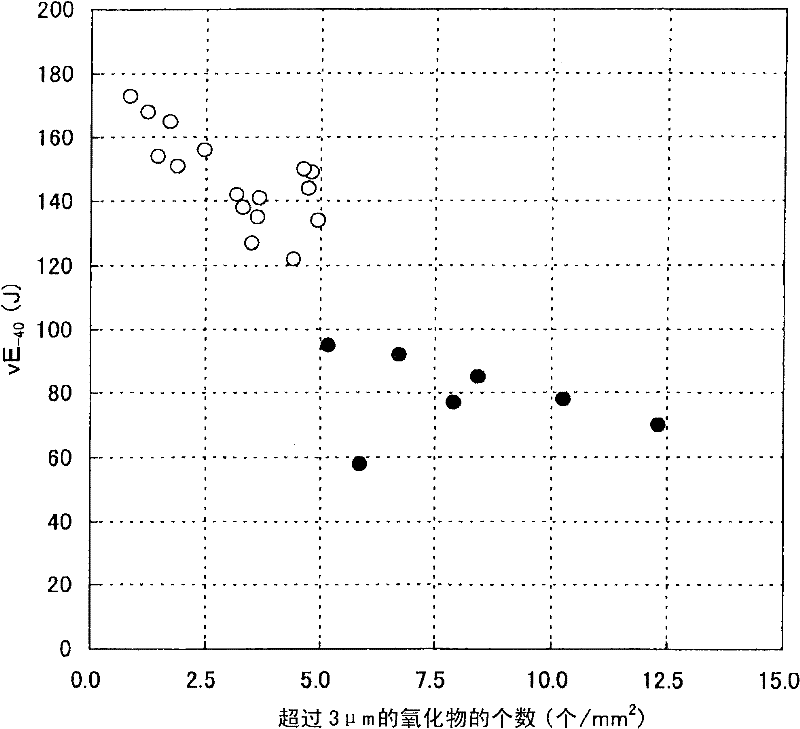

[0155] In Experimental Example 1, the relationship between the requirements specified in (a) to (c) above and HAZ toughness was studied, and in Experimental Example 2, the above (d) and (e) The relationship between the elements and HAZ toughness is studied.

[0156] [Experimental example 1]

[0157] Using a vacuum melting furnace (capacity 150kg), under the conditions shown in the following Table 1, the test steel (the balance is iron and unavoidable impurities) with the composition (mass %) shown in the following Table 2 and Table 3 was melted. , cast into 150kg ingots and cooled. Thereafter, heating and rolling are performed to produce thick steel plates. In addition, among the test steels shown in Table 2 and Table 3 below, it was confirmed that the total O content of the test steel satisfying the requirements specified in the present invention was in the range of 0.0005 to 0.010%.

[0158] When melting the above test steel in a vacuum melting furnace, adjust the composi...

experiment example 2

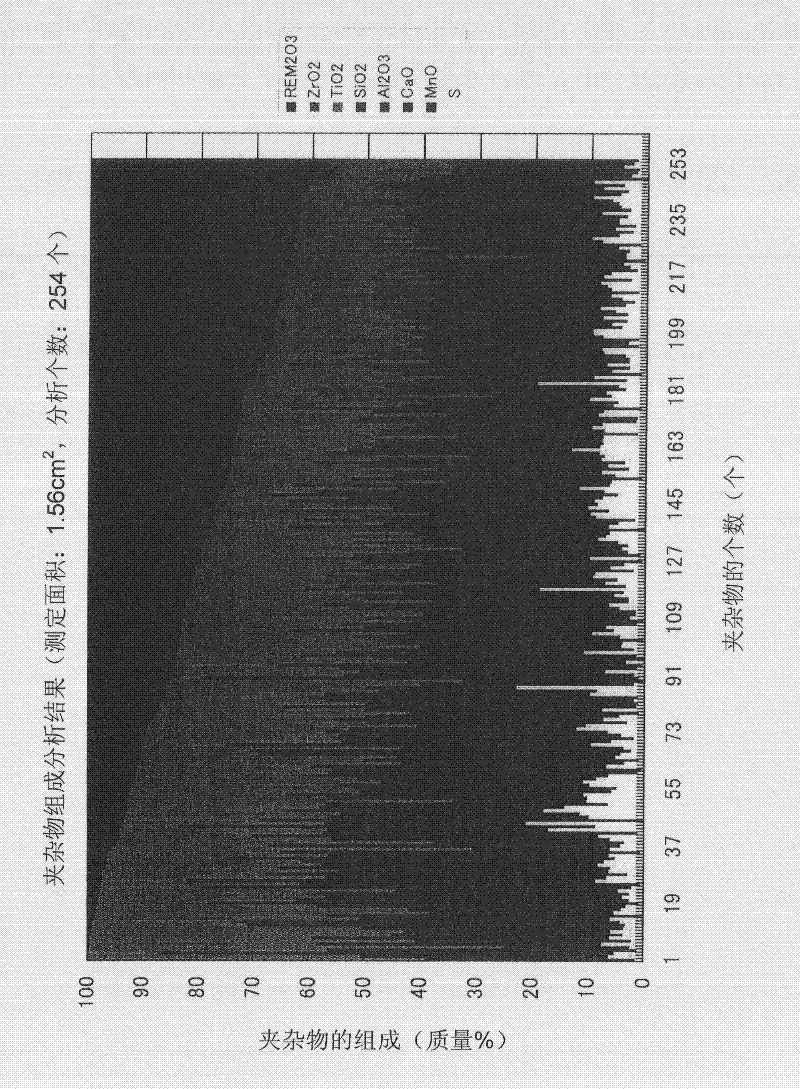

[0187] Regarding Nos. 1, 3, 8, 11, and 13 to 16 shown in Table 4 above, the relationship between the composition of each inclusion contained in the steel material and the HAZ toughness was investigated.

[0188] The composition of each inclusion contained in the steel material was measured in the following procedure. That is, in the same manner as in Experimental Example 1 above, using EPMA ("JXA-8500F (device name)") manufactured by JEOL Datum Co., Ltd., the surface of the cut sample was observed, and the inclusions with an equivalent circle diameter of 0.1 μm or more were quantitatively analyzed. ingredients.

[0189] As an example of quantitative analysis, the composition of each inclusion contained in No. 1 steel shown in Table 4 above was analyzed, and the results are shown in image 3 middle. The X-axis represents the number of observed inclusions, and the Y-axis represents the composition of each inclusion, and each component is distinguished by color. at 1.56cm 2 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com