Thick steel plate

A thick steel plate, high-quality technology, applied in the field of thick steel plate, can solve the problems of low yield ratio, small line energy, etc., achieve the effect of low yield ratio, ensure the toughness of the base metal, and good HAZ toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

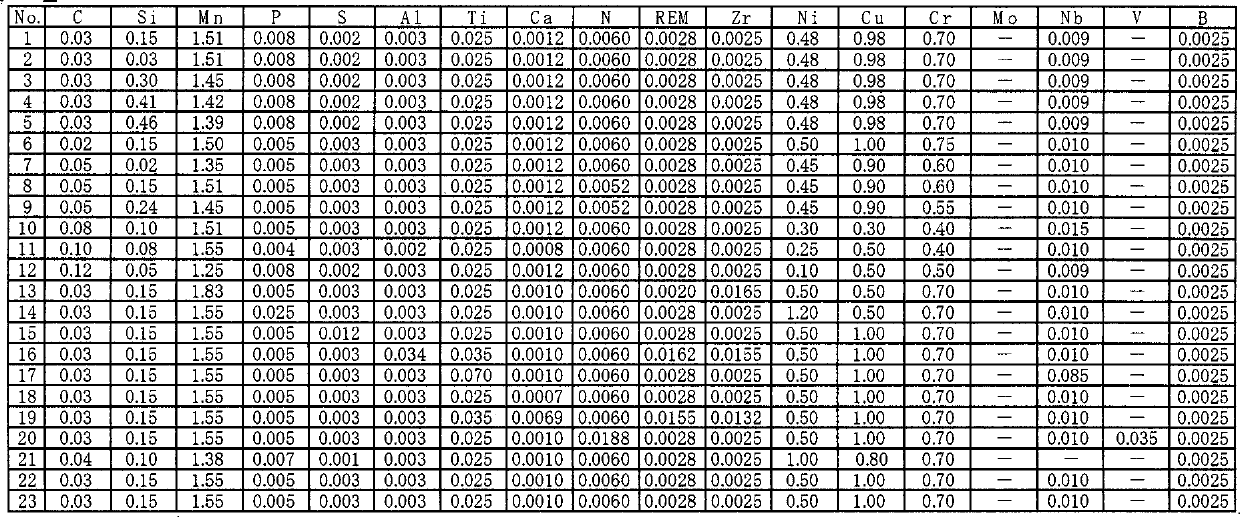

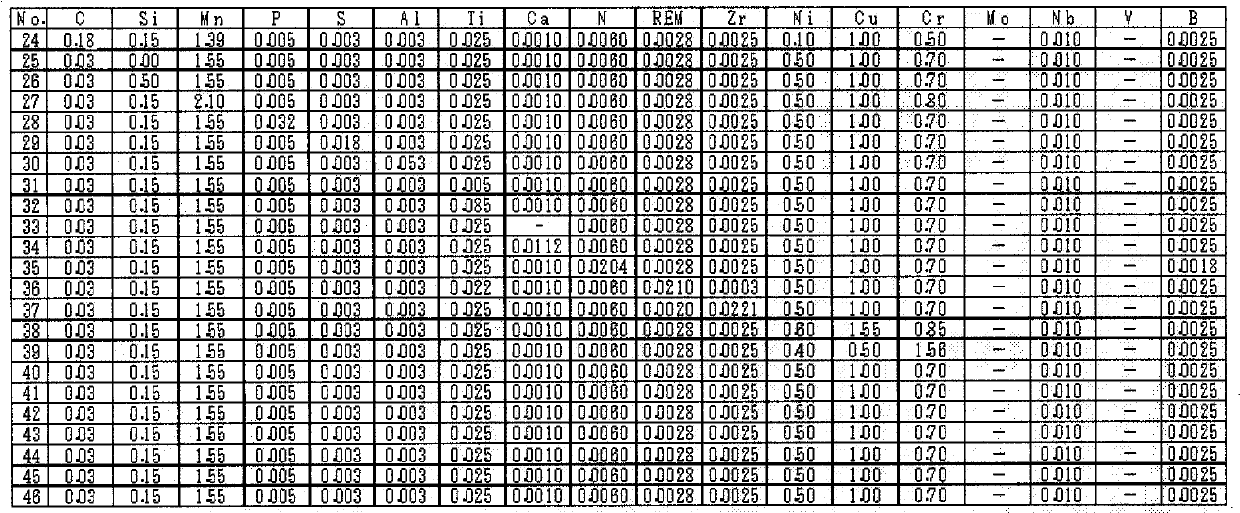

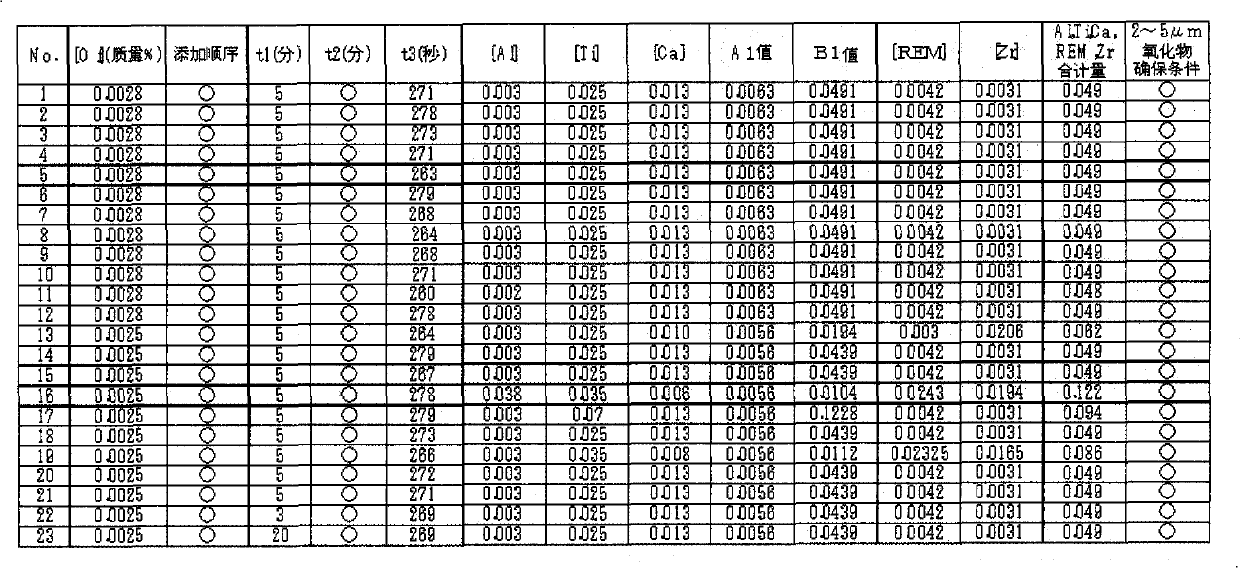

Examples

Embodiment Construction

[0057] Hereinafter, first, the basic configuration of the present invention will be described.

[0058] Develop thick steel plates used in welded structures such as bridges, high-rise buildings, and ships, especially thick steel plates with excellent toughness in the weld heat-affected zone when welding with a large heat input of 100kJ / mm or more. In the case of steel sheets, first, the inventors focused on the fact that high HAZ toughness can be secured by utilizing oxide-based inclusions (hereinafter, all are simply referred to as oxides), and studied from various angles.

[0059] There are advantages and disadvantages in the HAZ toughness improvement technology of a thick steel plate using this oxide. The advantage is that the oxide becomes the starting point of intragranular α formation, which makes the HAZ structure finer and improves the toughness of the HAZ. On the contrary, the disadvantage is that the oxide itself becomes the starting point of destruction, which adver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com