High tension steel plate with excellent weldability

A high-tensile and weldable technology, applied in the field of high-tensile steel plates, can solve the problems of unreachable, and achieve the effect of good HAZ toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

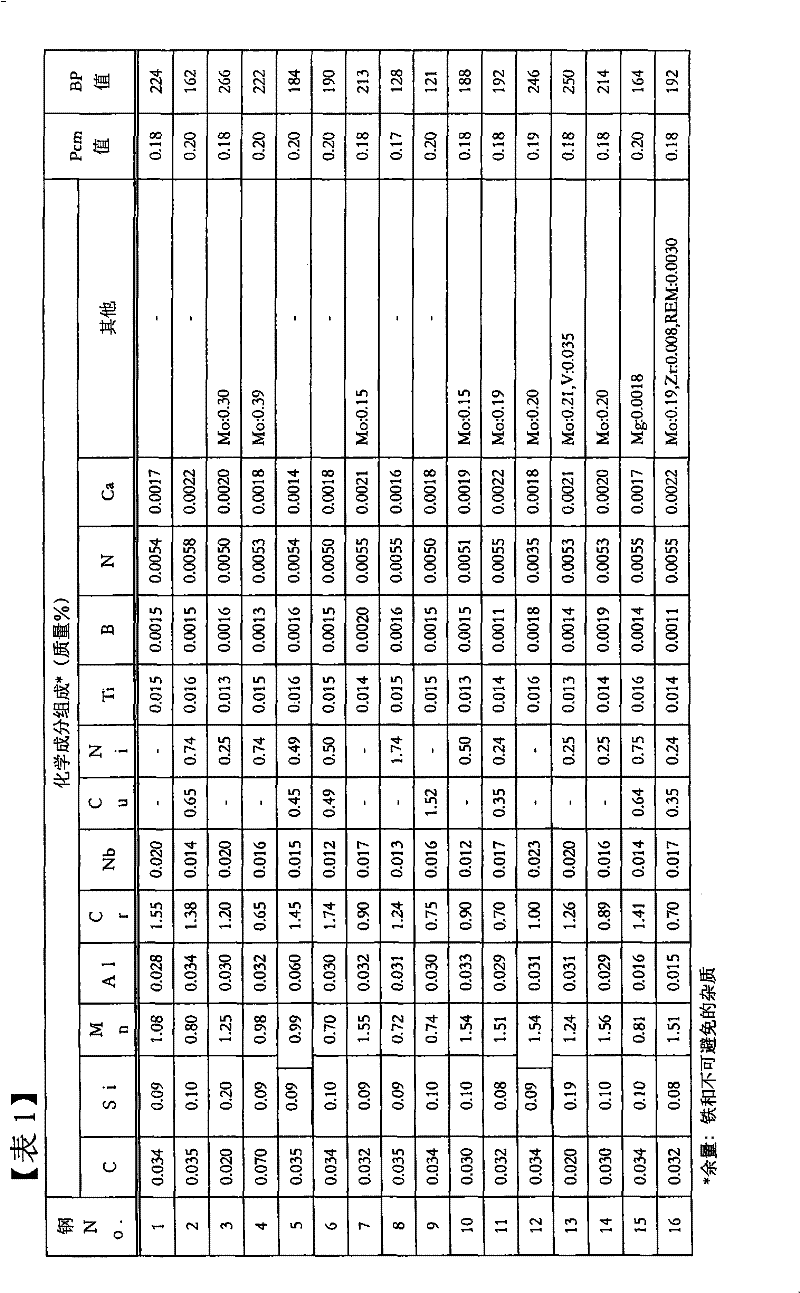

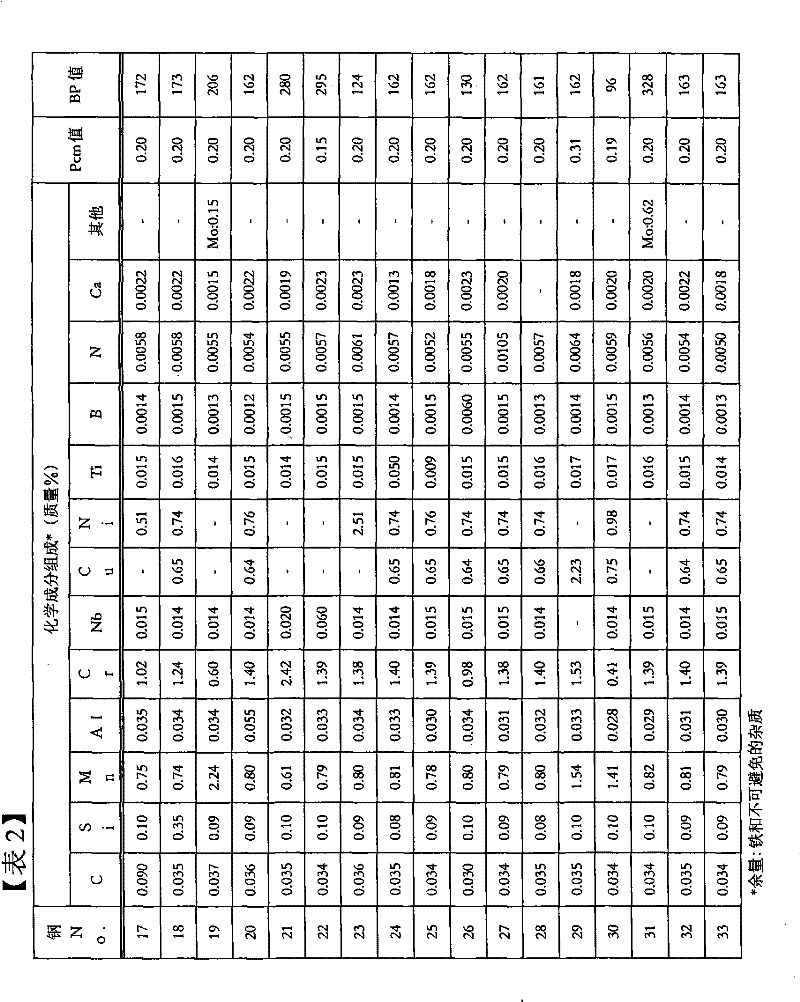

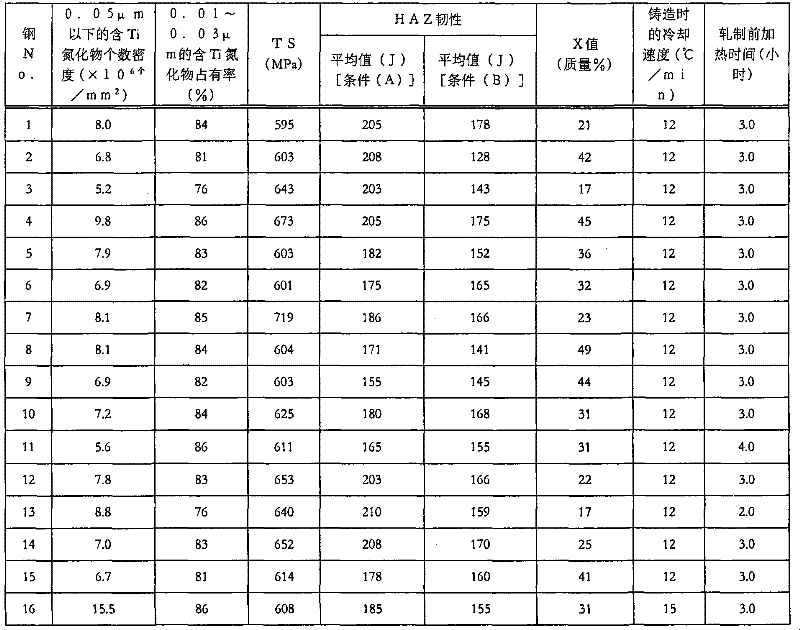

Examples

Embodiment Construction

[0021] A steel plate with a strength exceeding 590 MPa will form a bainite structure in the HAZ, but there are many unknown points about the influence of alloying elements on the bainite structure. The inventors of the present invention conducted research on the bainite microstructure and alloy design principles in order to understand the influence of alloying elements on the HAZ toughness of bainite steel sheets.

[0022] As a result, the idea was obtained that good HAZ toughness can be ensured if the bainite structure (bainite block size) of the HAZ is made finer than 10 μm. Next, the miniaturization of the bainite block is considered to be related to the transformation driving force of the bainite structure, and the influence of various alloys was studied considering that it is only necessary to design the composition to increase the transformation driving force.

[0023] If the formation process of bainite transformation is considered, it is considered that the driving for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com