Heavy steel plate

A thick steel plate and quality technology, applied in the field of thick steel plate, can solve the problems of decreased productivity, increased number of processes, increased manufacturing cost, etc., to achieve the effect of good substrate toughness and improved uniform elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0121] (Example of the steel plate of the present first invention)

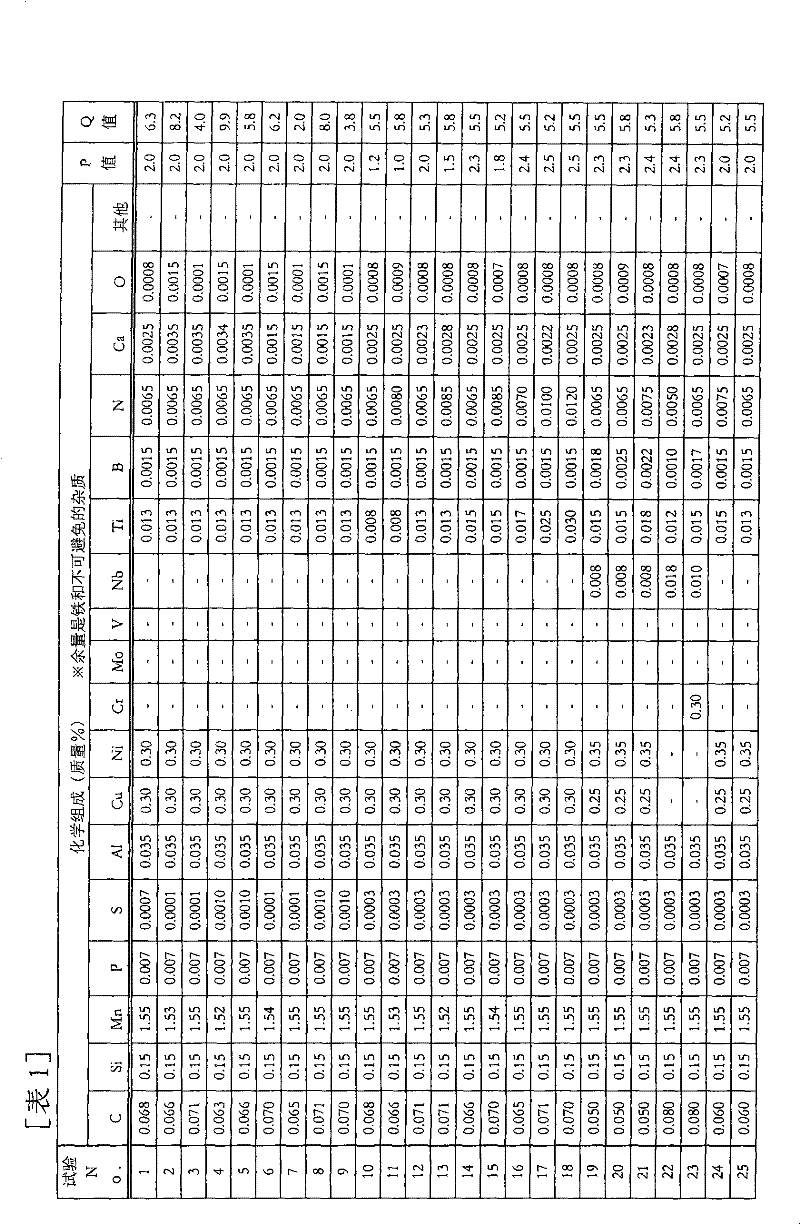

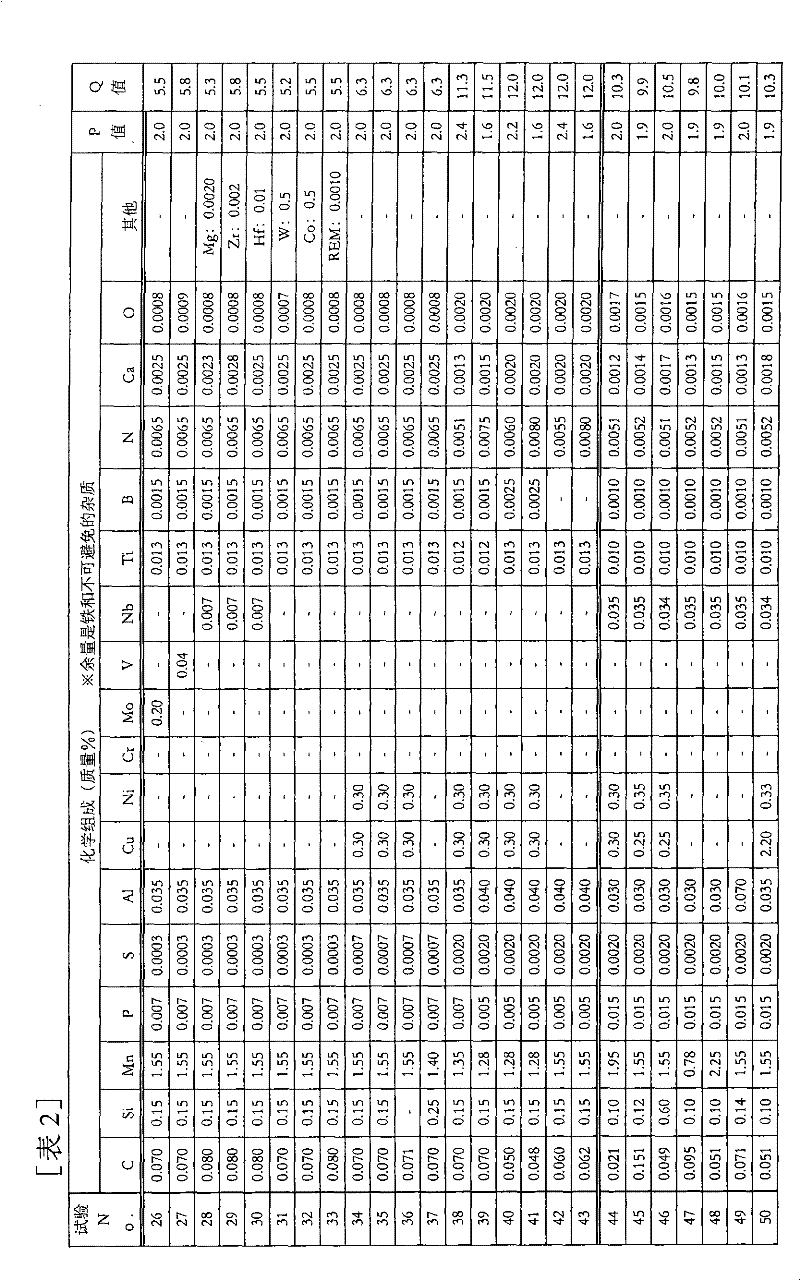

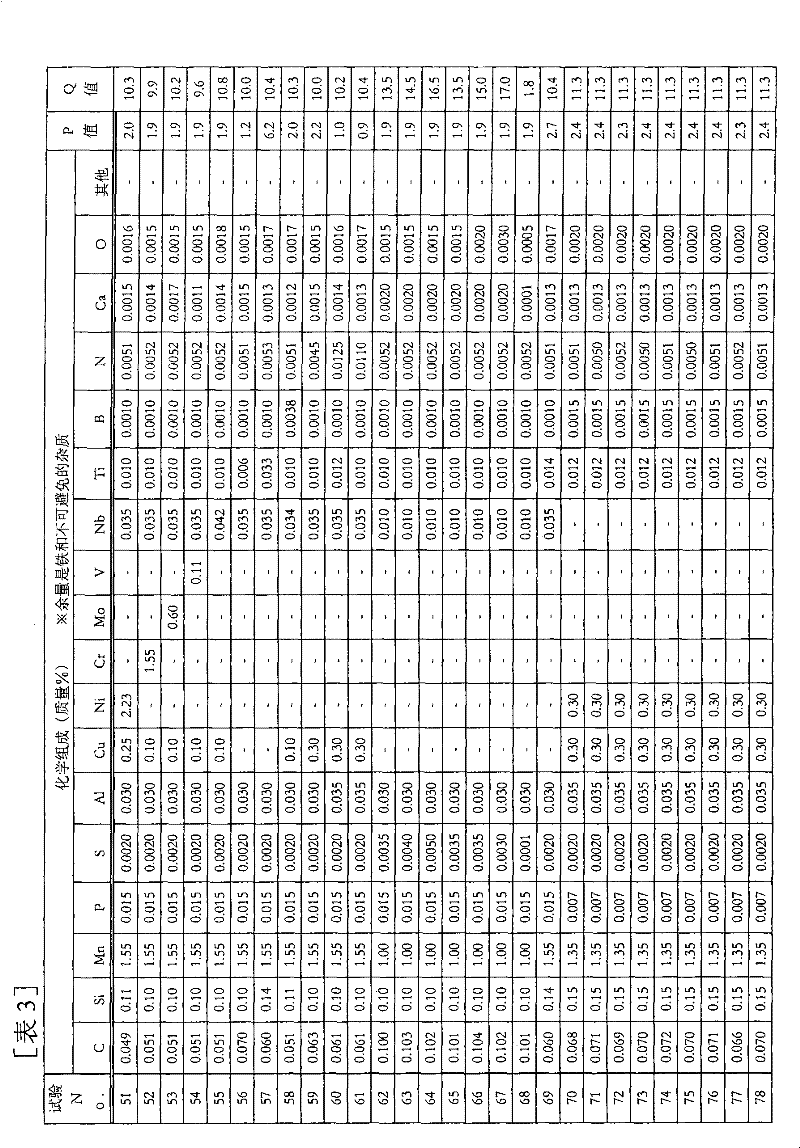

[0122] Smelt the steel with the composition shown in the following Tables 1 to 3 by a common melting method, and cool the molten steel from 1500°C to 1100°C at a cooling rate of 0.1 to 2.0°C / min to obtain a slab (slab thickness = 270mm ). Thereafter, hot rolling and quenching shown in Tables 4 and 5 were performed on this slab to obtain a steel plate with a thickness of 60 mm. In addition, Table 4 shows the conditions of quenching method A, and Table 5 shows the conditions of quenching method B. In addition, in Table 1, REM is added in the form of a rare earth metal alloy containing about 50% of La and about 25% of Ce. In addition, "-" in Tables 1-3 shows that no element was added. In addition, Tables 1 to 3 also show the P value ([Ti] / [N]) and Q value [1000×([Ca]+2×[S]+3×[O]) specified in the present invention.

[0123]

[0124]

[0125]

[0126]

[0127] The tensile properties of the various...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com