High yield ratio high tension steel plate with excellent inhibition of fatigue craze progression and toughness of welding heat affected zone

A kind of steel plate and proportioning technology, applied in the field of high yield ratio and high tension steel plate, it can solve the problems that are not established, the crack progress speed and the state of grain boundaries are not considered, and the effect of good HAZ toughness and excellent inhibition of fatigue crack progress can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0122] The steel (steel types A to R) having the chemical composition shown in Table 2 below was used to manufacture steel sheets under the production conditions shown in Table 3 below. In addition, Table 2 also shows the PM value stipulated in the present invention. In addition, the steel types A to M in Table 2 satisfy the chemical composition composition specified in the present invention, and the steel types N to R deviate from the necessary conditions (chemical composition composition, PM value) specified in the present invention.

[0123] 【Table 2】

[0124]

[0125] 【table 3】

[0126]

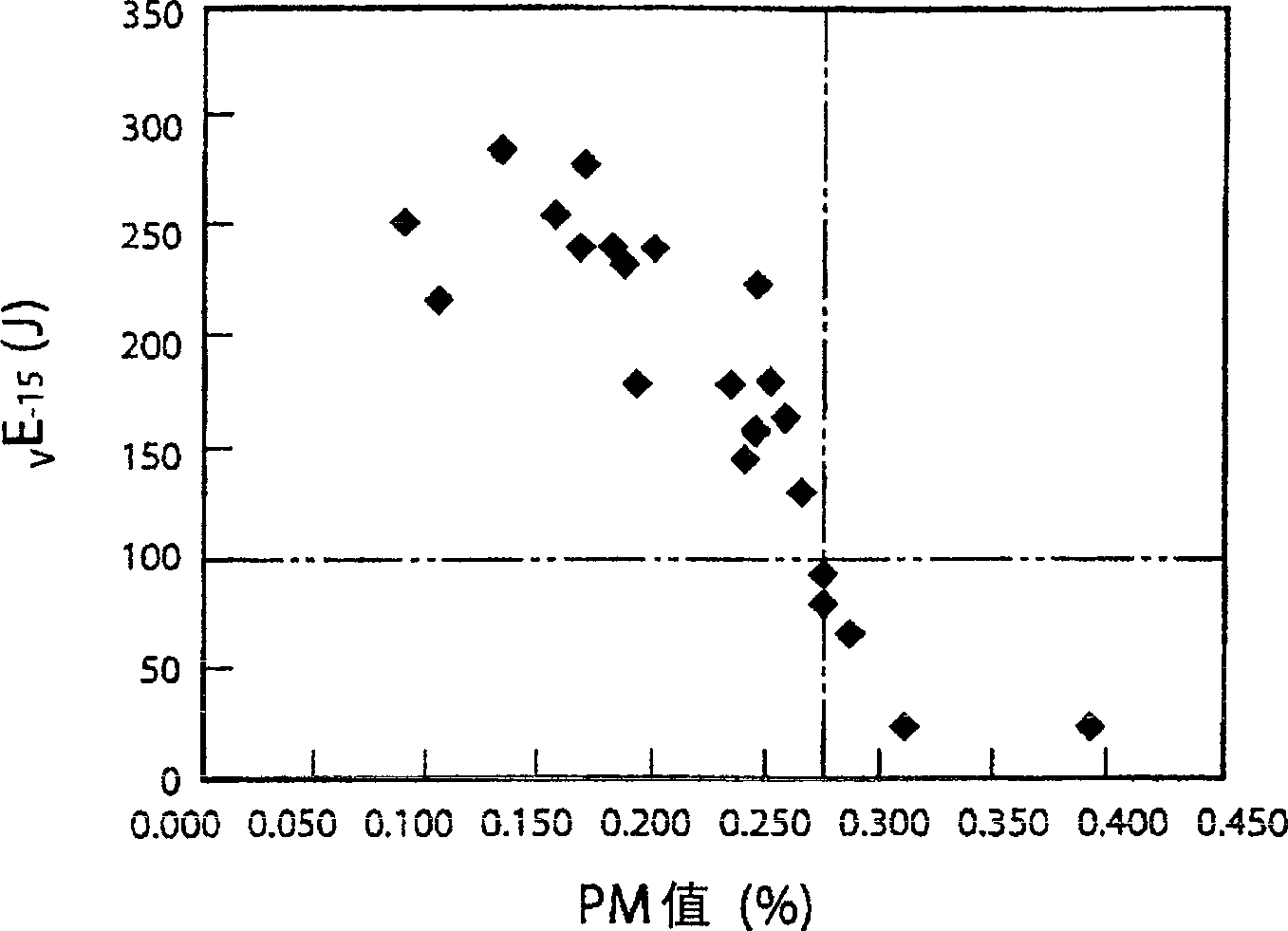

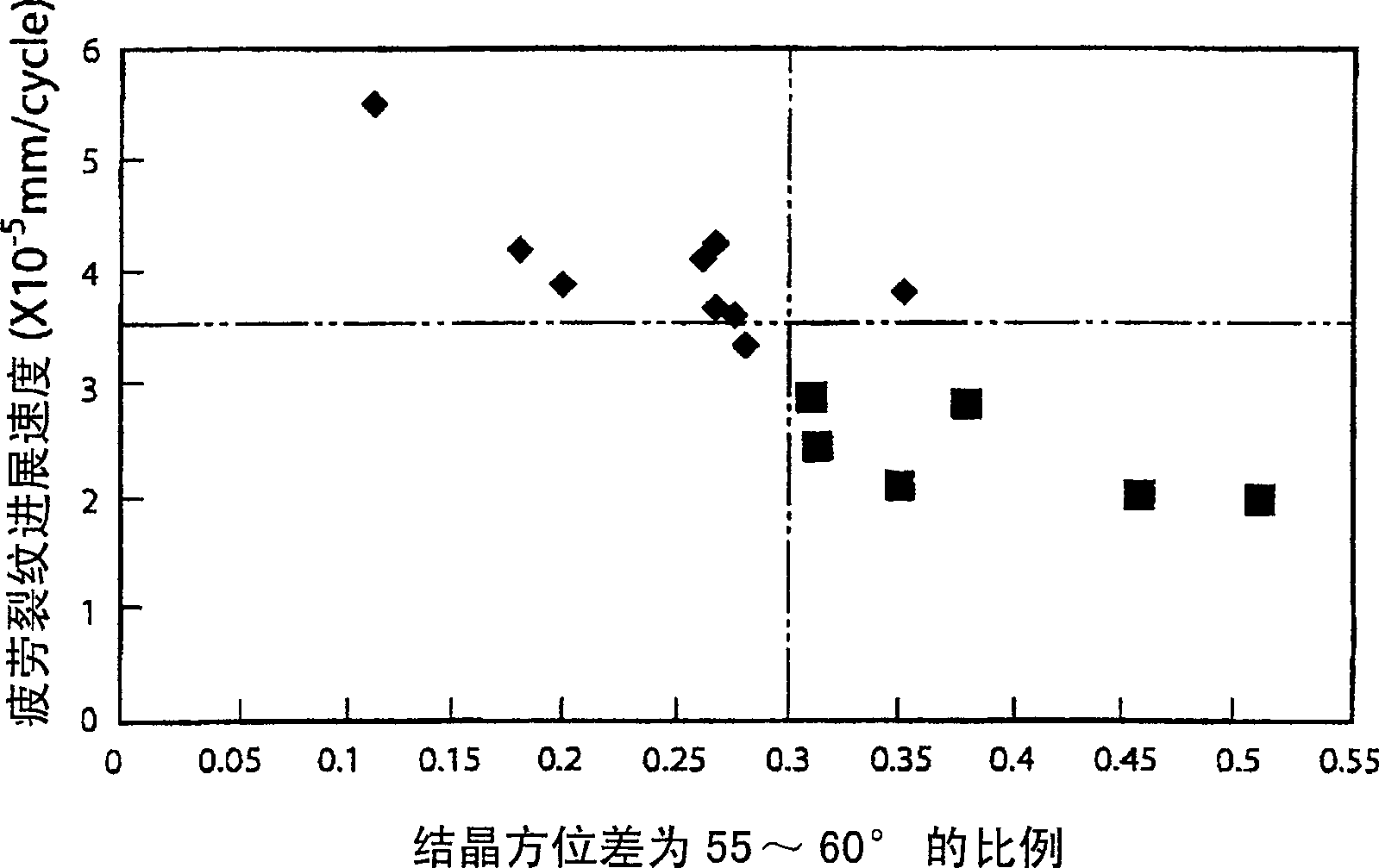

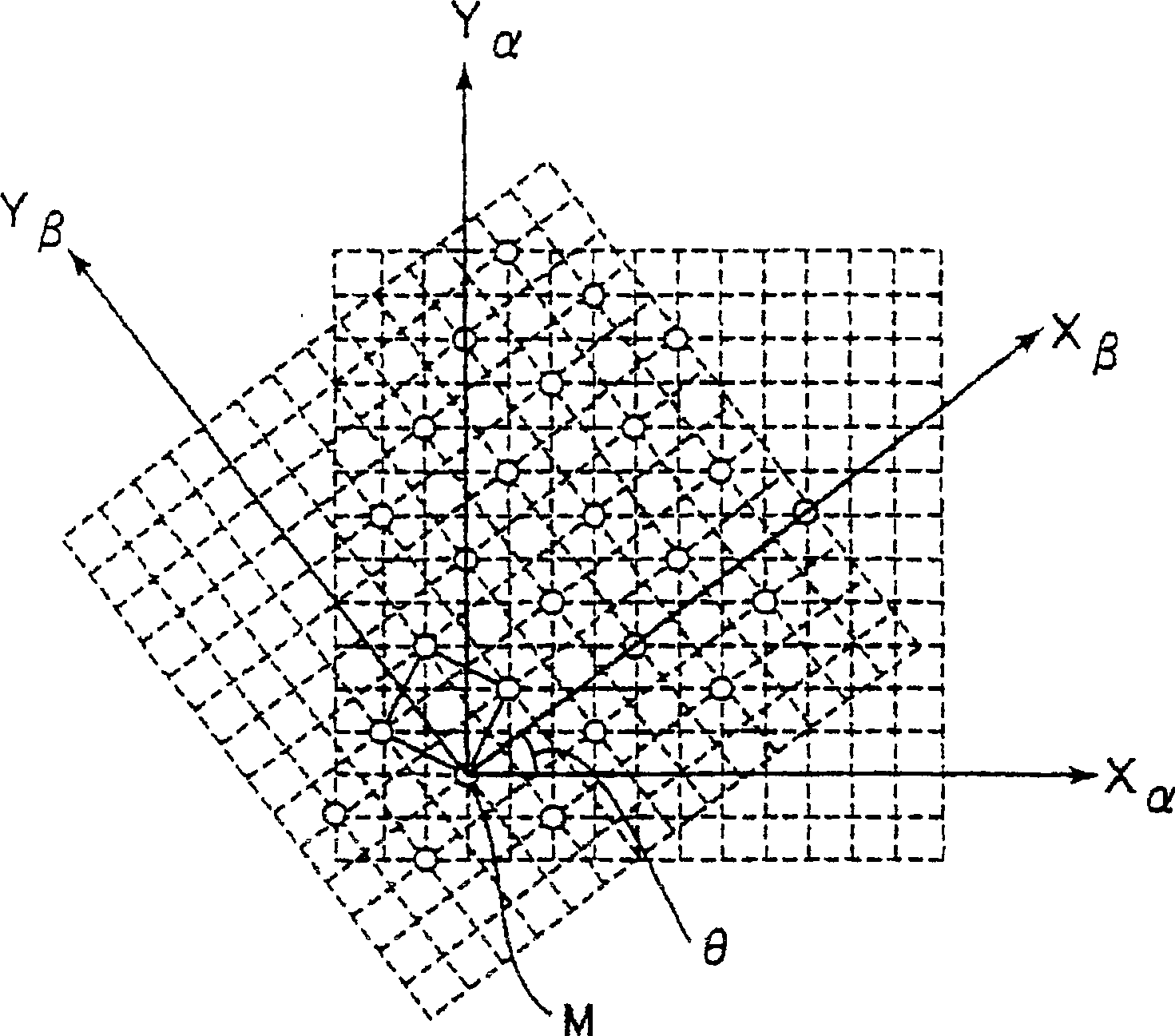

[0127] For each steel plate obtained, the bainite fraction and the tensile properties of the steel material (base material) [0.2% yield point (YS), tensile strength (TS), yield ratio (YR: YS / TS)], impact characteristics (fracture transition temperature vTrs), welding low-temperature cracking resistance, HAZ toughness, etc., and the large-angle grain boundary diameter (average equivalent ...

Embodiment 2

[0157] Using the steel type A shown in Table 2 above, the same HAZ reproduction test as in Example 1 except for changing the heat energy was performed. Heat energy input at this time: equivalent to 1-20KJ, change the cooling time to 800-500℃ to conduct the thermal cycle test. In addition, the cooling time is 10 seconds when the heat input is 1KJ / mm, the cooling time is 20 seconds when the heat input is 2KJ / mm, the cooling time is 40 seconds when the heat input is 5KJ / mm, the cooling time is 60 seconds when the heat input is 7KJ / mm, and the heat input is 15KJ. The cooling time is 120 seconds when / mm, and the cooling time is 160 seconds when the heat input is 20KJ / mm.

[0158] After that, two pendulum impact test pieces (JIS Z 2202V notched test pieces) were extracted from each test piece, and 10 pieces for each steel plate were calculated to obtain the average impact absorption energy vE at -15°C -15 .

[0159] The results are shown in Table 5 below. However, in the high-tensile s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com