Thick steel plate

A technology of thick steel plate and plate thickness, applied in the field of thick steel plate with excellent base metal and HAZ toughness, can solve the problems of toughness deviation, adverse effect of toughness, base metal and HAZ toughness deviation, etc., to achieve the effect of toughness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

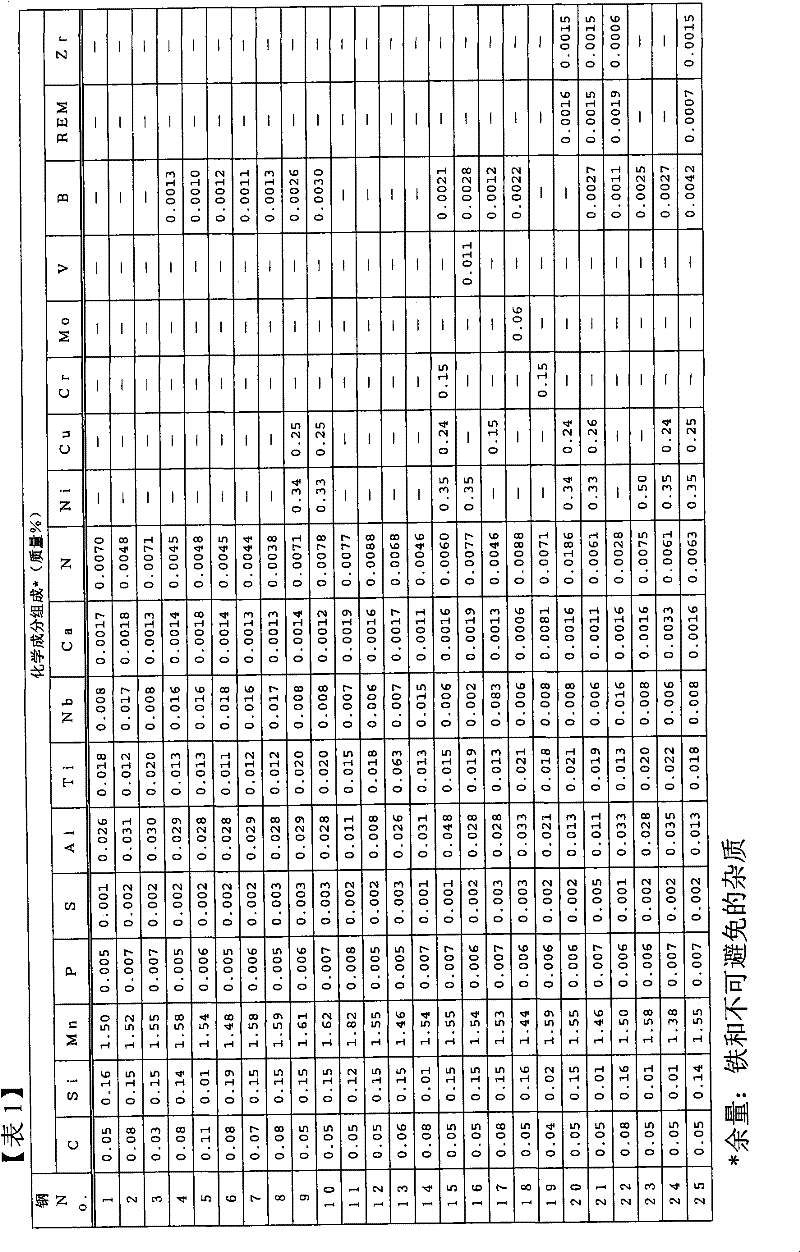

[0110]While controlling the conditions shown in the following Tables 3 and 4 (the order of addition of Al and Ca, and the holding time T1 until casting), the steel with the composition shown in the following Tables 1 and 2 was smelted while controlling the casting time (1500~ 1400°C temperature range) for the cooling time T2, while cooling the molten steel to form a slab (cross-sectional shape: 150mm×250mm), the rolling conditions shown in the following Tables 3 and 4 (heating temperature Th before rolling, Pre-rolling heating time T3, rough rolling end temperature Tf) rolling to become a hot-rolled sheet with a plate thickness of 80 mm, and cooling to the cooling stop temperature Ts at the cooling rate Rc after rolling. In addition, tempering treatment is performed at 500° C. as necessary. In addition, in Table 1, REM is added in the form of misch metal containing about 50% of la and about 25% of Ce. In addition, "-" in Table 1 indicates that no element was added. In Tables...

Embodiment 2

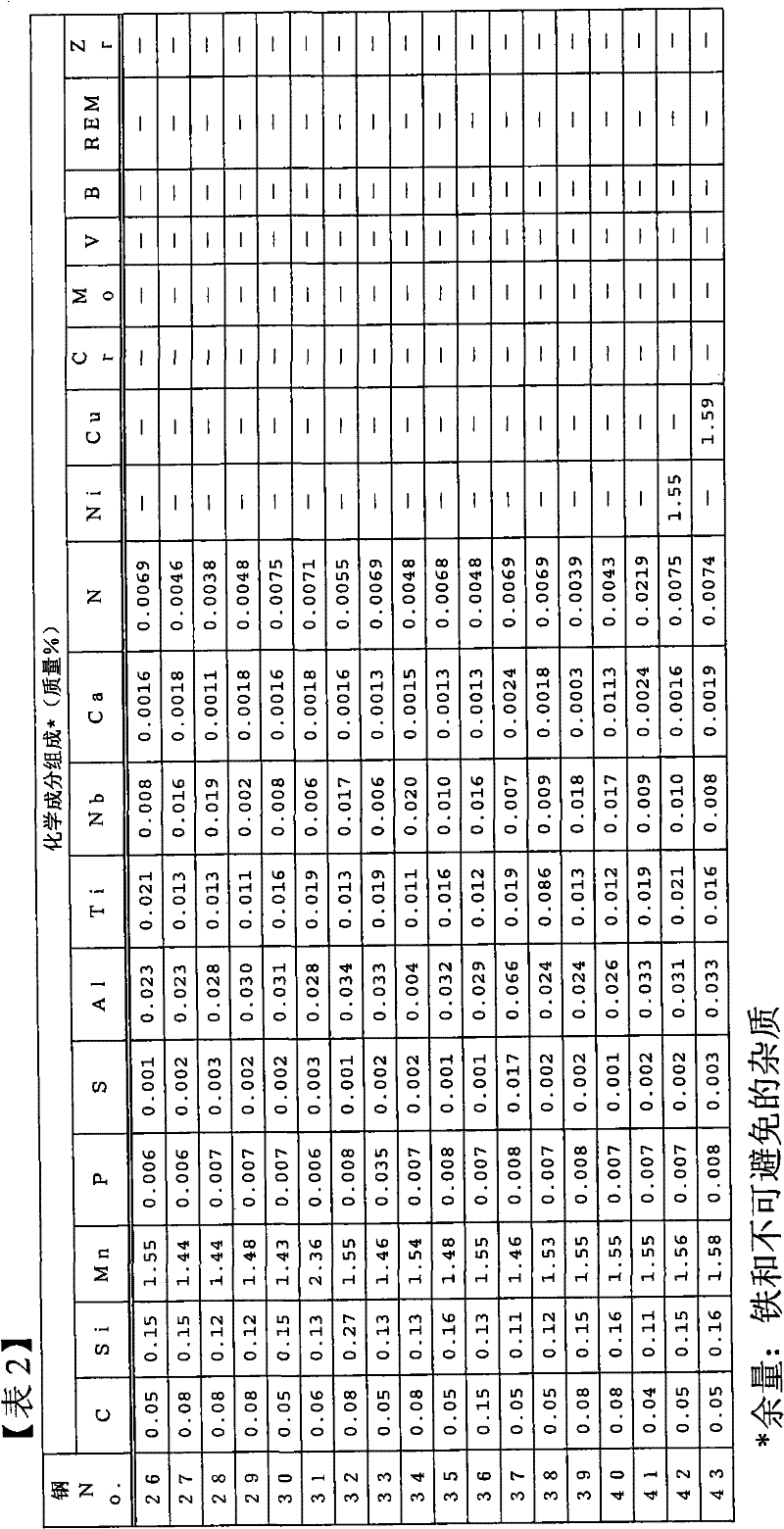

[0144] Under the conditions shown in Tables 10 to 12, steels with the chemical composition shown in Tables 7 to 9 were smelted and cast to form slabs (cross-sectional shape: 150 mm × 250 mm), and then hot rolled to obtain hot rolled slabs with a thickness of 80 mm. plate. In addition, in Tables 7 to 9, REM is added in the form of mischmetal containing about 50% of la and about 25% of Ce. In addition, in Tables 10 to 12, the addition order of Al and Ca is "◯", which means that they are added in the order of Al→Ca.

[0145]

[0146]

[0147] Test pieces were cut from the hot-rolled sheets obtained above, and the number density of Ti-containing nitrides of various sizes was measured in the same manner as in Example 1, and the HAZ toughness was measured in the following manner.

[0148] Determination of HAZ toughness

[0149]A pendulum impact test piece (standard test piece specified in JISZ 2242) was taken from a position t / 4 deep from the surface of each hot-rolled she...

Embodiment 3

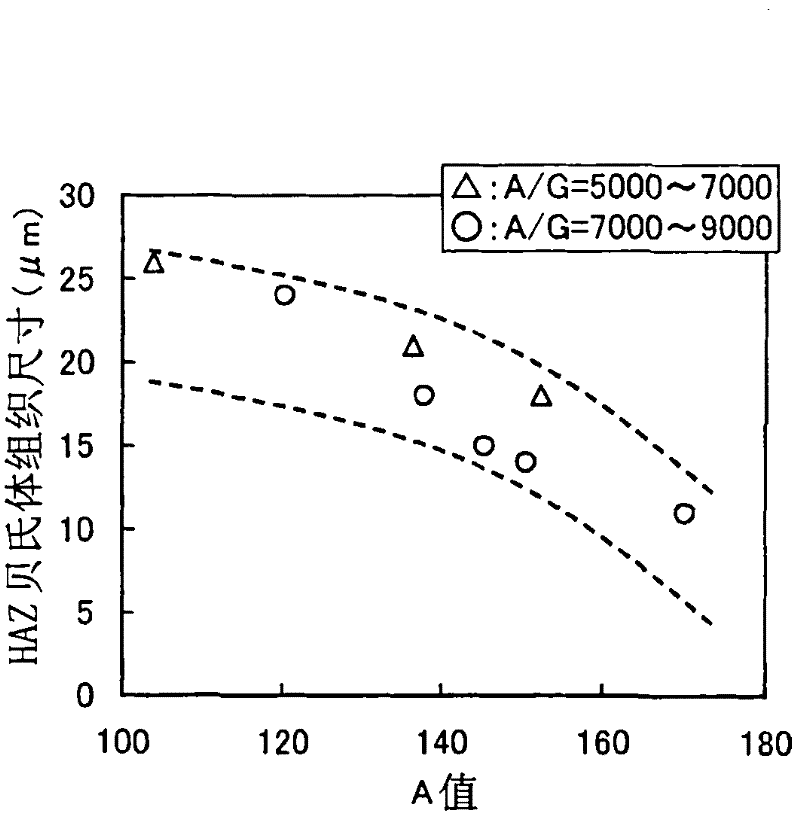

[0158] In No.1~3,5,14 of table 10 of described embodiment 2, No.31 of table 11 and Ni.c, d of table 12, extract test piece (12.5mm * 32mm) from the hot-rolled plate × 55mm), the same thermal cycle test as in Example 2 was carried out. In this test piece, EBSP (Electron Back-Scattering Pattern) measurement (field of view: 200 μm × 200 μm) was performed on a portion corresponding to a position at a depth of t / 4 from the surface of the hot-rolled sheet. The average grain size of the HAZ bainite structure surrounded by high-angle grain boundaries with a crystal orientation difference of 15° or more. The results are shown in Table 13, figure 1 middle.

[0159] 【Table 13】

[0160]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com