Mud-sucking device provided with dredging mechanism

A mud suction pipe and mud collecting tank technology, which is applied in the direction of mechanically driven excavators/dredgers, can solve the problems of inconvenient mud suction pipes, sludge blockage, low work efficiency, etc., and achieve the effect of dredging and easy to see.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

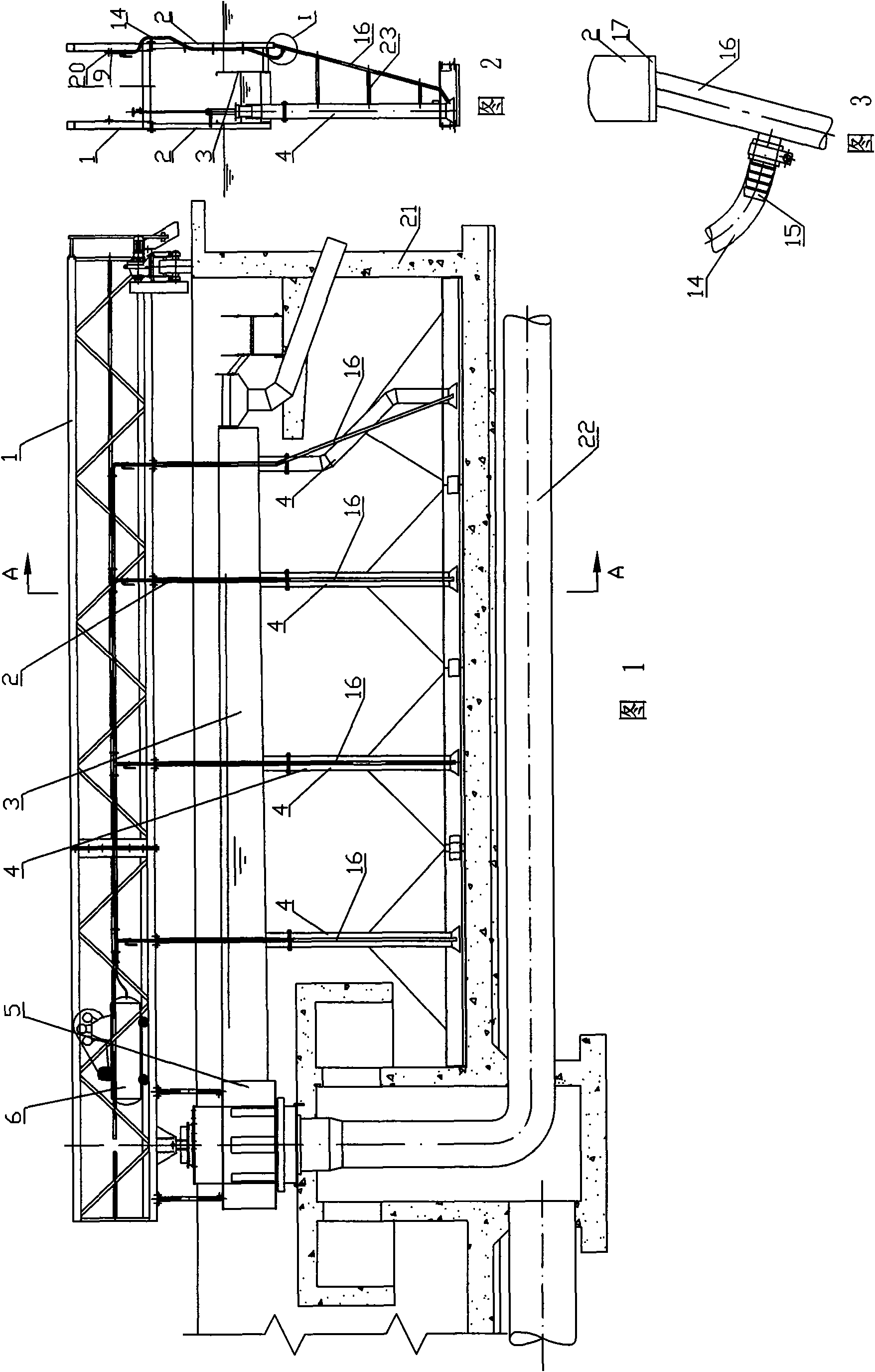

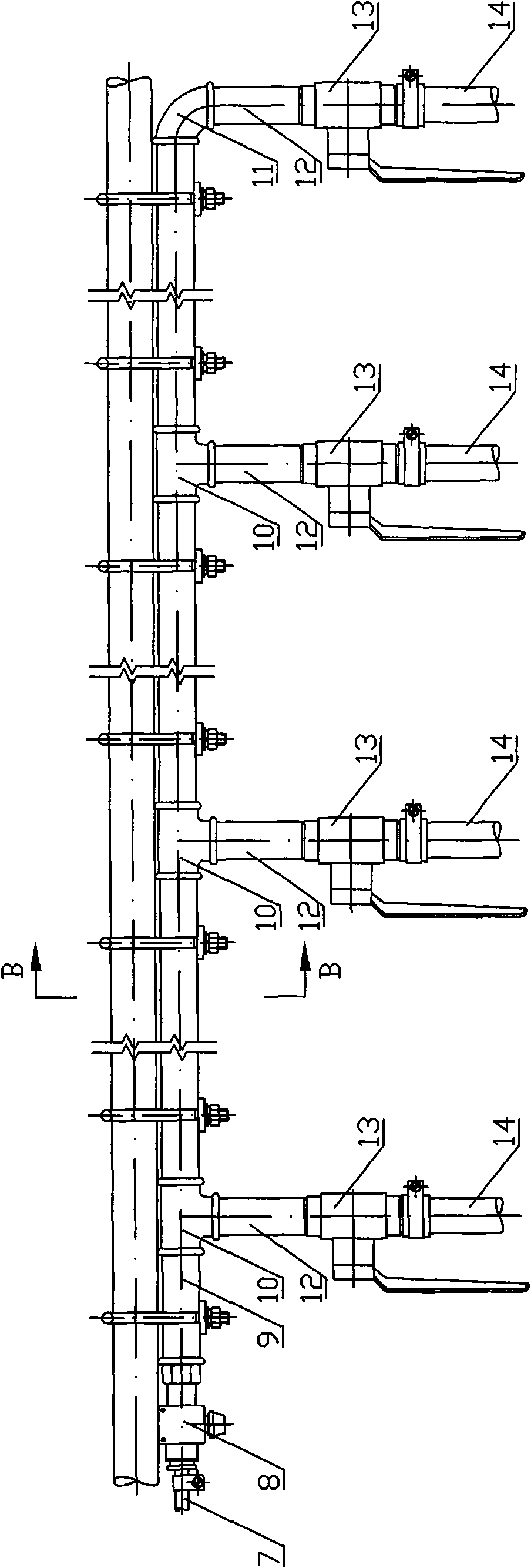

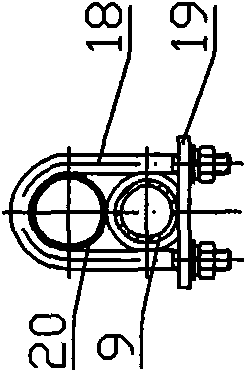

[0015] As shown in the figure: the mud suction device with a dredging mechanism includes the working bridge 1 and the mud collecting tank 3 located below the working bridge 1. The inner end of the mud collecting tank 3 arranged in the horizontal direction is the central mud tank 5. Several vertically arranged dredging pipes 4 are arranged below the groove 3, and a total dredging pipe 22 is arranged below the center mud tank 5; 4 corresponds to the branch pipes 12 one by one, and the outlet end of each branch pipe 12 is connected to the bottom of the corresponding dredge pipe 4 by means of a respective air branch rubber pipe 14 .

[0016] The outlet end of the air branch rubber pipe 14 can be connected with the cable-stayed pipe 16 first, and the outlet end of the cable-stayed pipe 16 is then connected with the bottom of the suction pipe 4 . The main air hose 7 should be installed at the inlet end of the main pipe 9, and the inlet end of the air hose 7 is connected to the air c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com