Insole structure of sneakers

A technology of sports shoes and mesh cloth, which is applied in the field of shoe soles to achieve the effect of improving tear resistance and tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

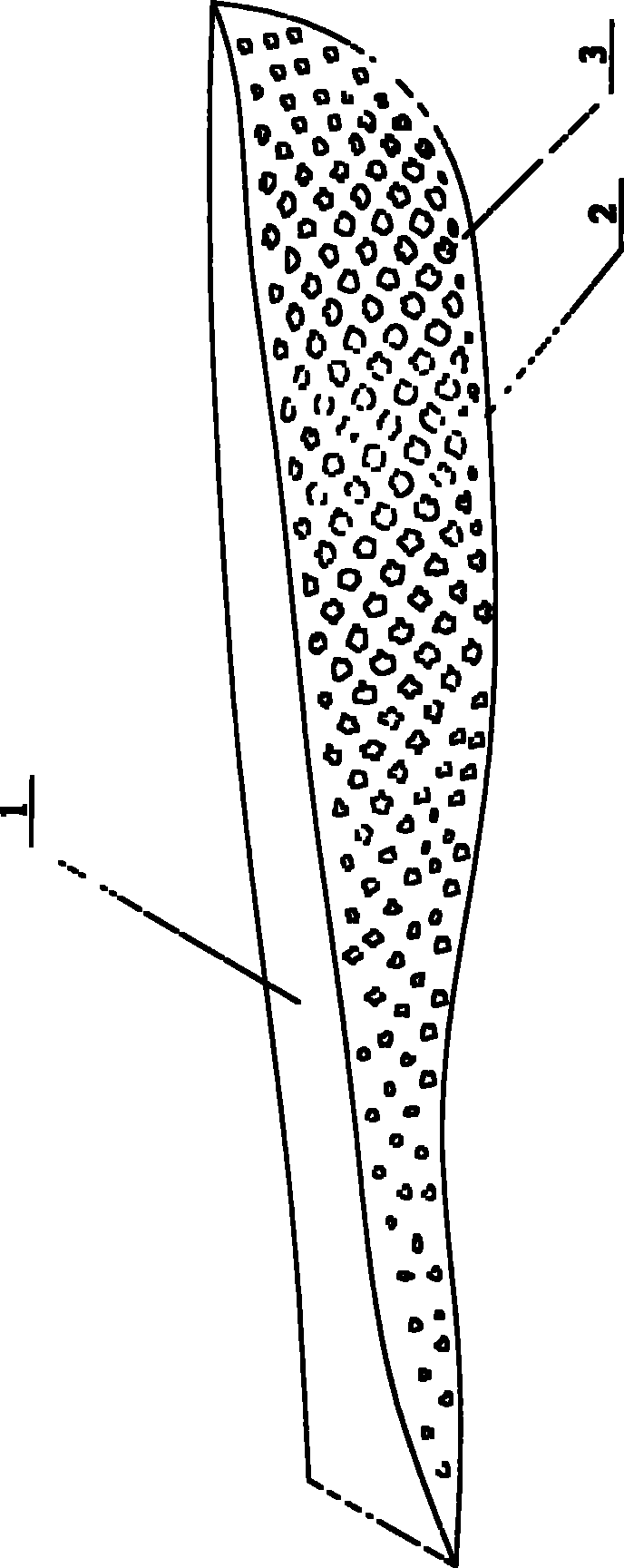

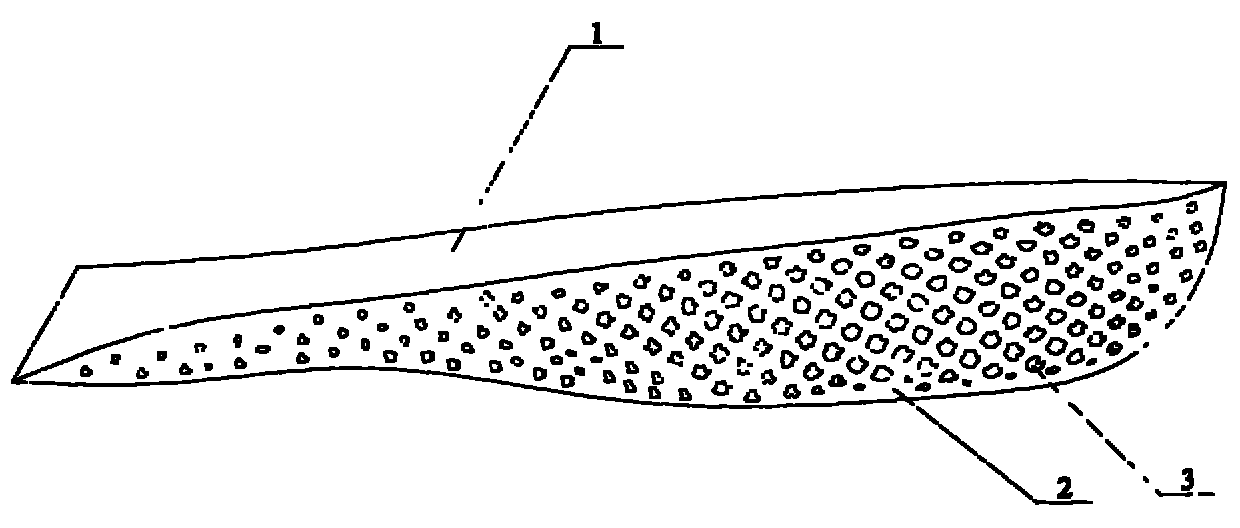

[0017] Table 1 shows the tearing load test data of the midsole without mesh and inlaid hexagonal or circular mesh shape mesh, where the area of a single mesh is 5mm 2 , the grid area in the mesh 2 accounts for 90% of the entire mesh area, and the height of the protrusion 3 is 0.5mm. When using the crack load method, the laboratory researchers first thought of the hexagonal shape, that is, the shape of the honeycomb. This shape can fully disperse the pressure well during the stretching and tearing process in all directions. For other shapes, the circle is the most suitable. Close to the hexagon, in advanced mathematics, the polygon is infinitely close to the circle, but the circle is easy to deform under the force and the pressure distribution is not as good as the hexagon, and other geometric shapes are not as good as the six in terms of force resistance, deformation resistance and pressure distribution. polygon. The tensile testing machine conforms to the regulations of QB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com