Screw tape locking device and nail tape transmission device therein

A technology of locking devices and screw straps, which is applied to screwdrivers, wrenches, manufacturing tools, etc., can solve the problems of inaccurate screw strap displacement, inaccurate screw locking positions, and high cost, and achieve the effect of preventing the screw strap from retreating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below with regard to the structural composition of the screw belt locking device of the present invention and the effect that can be produced, with reference to the accompanying drawings, a preferred embodiment is described in detail as follows:

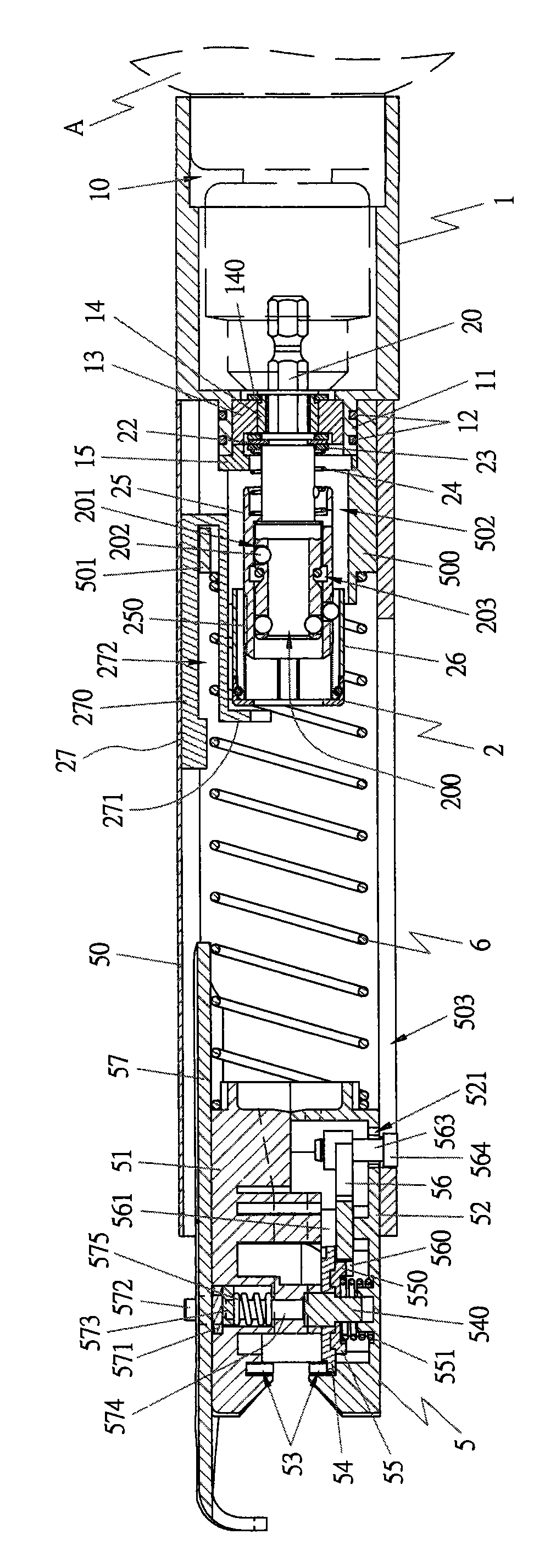

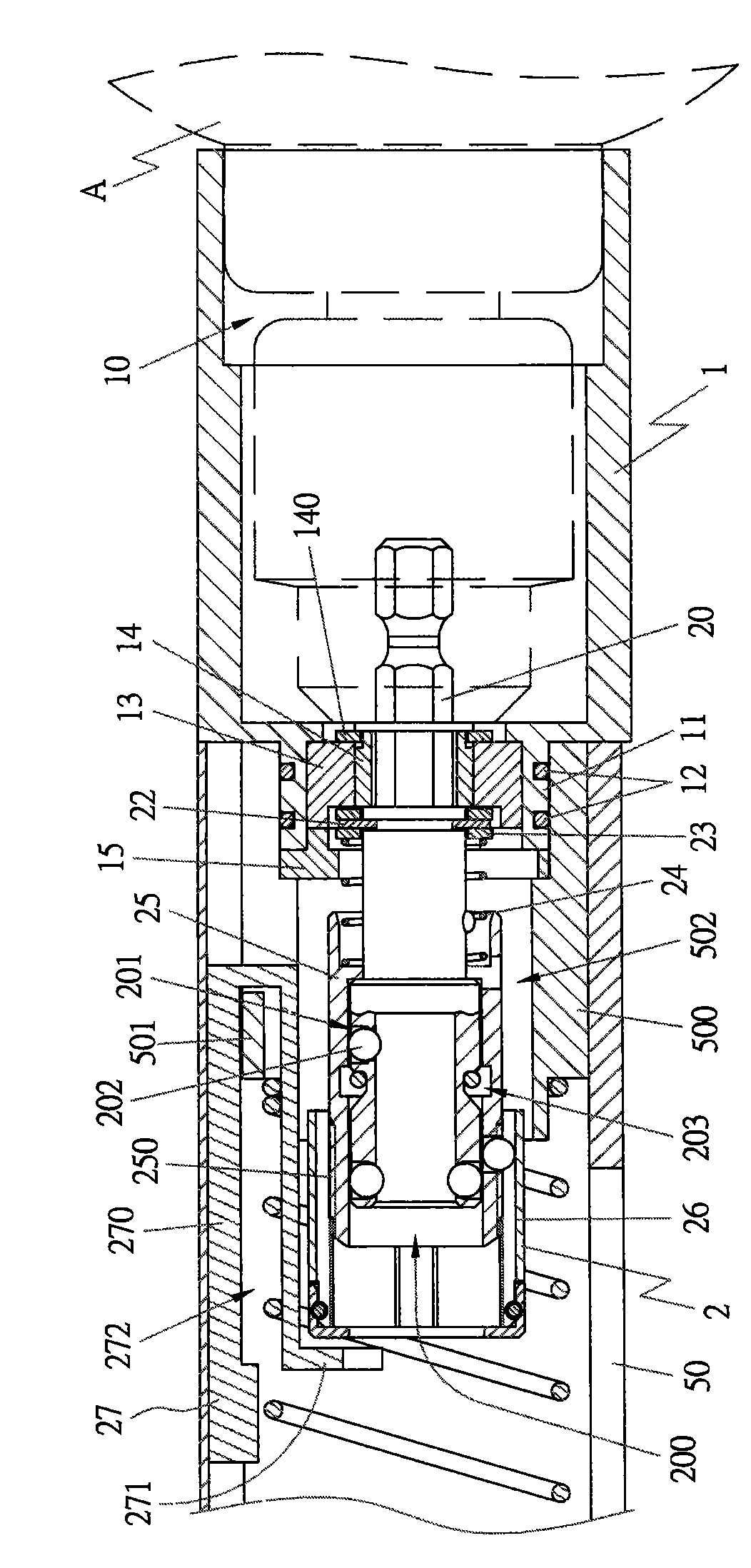

[0059] Such as figure 1 As shown, it is a cross-sectional view of the screw belt locking device of the present invention, which includes: a sleeve assembly 1, a torque release device 2, and a screw belt transmission device 5,

[0060] The sleeve assembly 1 is provided with a sleeve groove 10, and is connected with the power hand tool A through the sleeve groove 10, and the power hand tool A is used to drive the following components to operate.

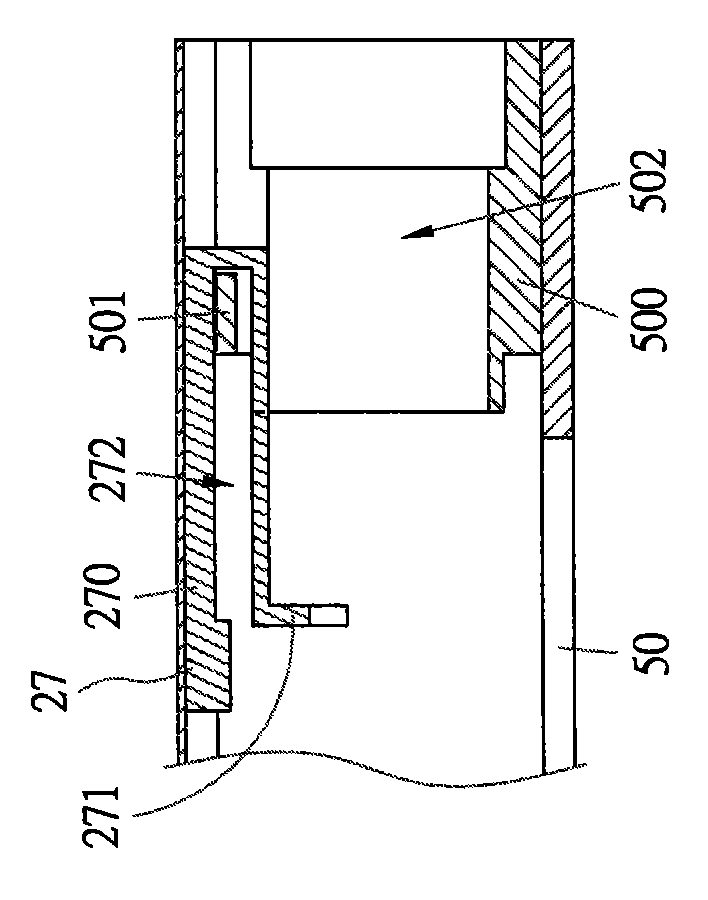

[0061] Such as figure 2 and 3 As shown, a bonding ring 11 with a smaller outer diameter is provided at the other end of the sleeve assembly 1, and a plurality of sealing rings 12 are provided on the surface of the bonding ring 11. The sealing rings 12 can be made of elastic plastic,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com