Minitype bearing five-point positioning ultra-precision bearing positioning mechanism

A technology of miniature bearings and positioning mechanisms, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as inaccurate positioning and unstable ultra-precision depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

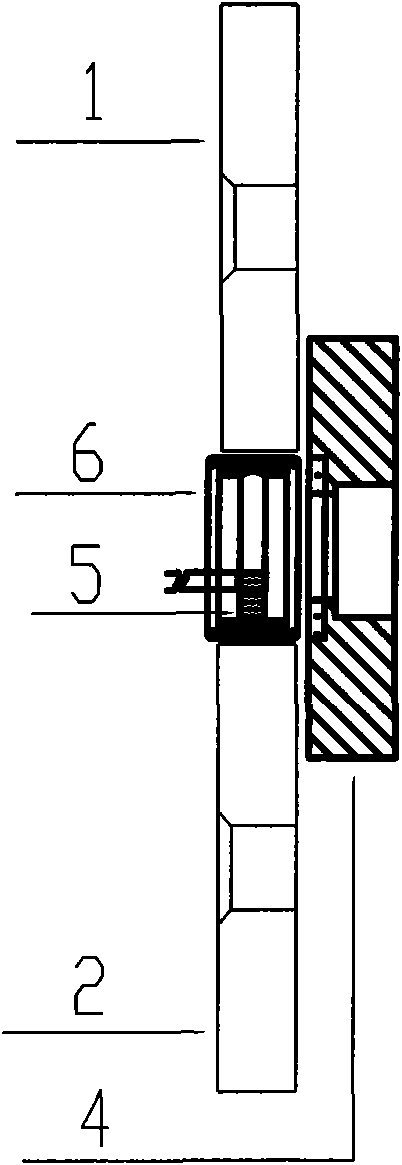

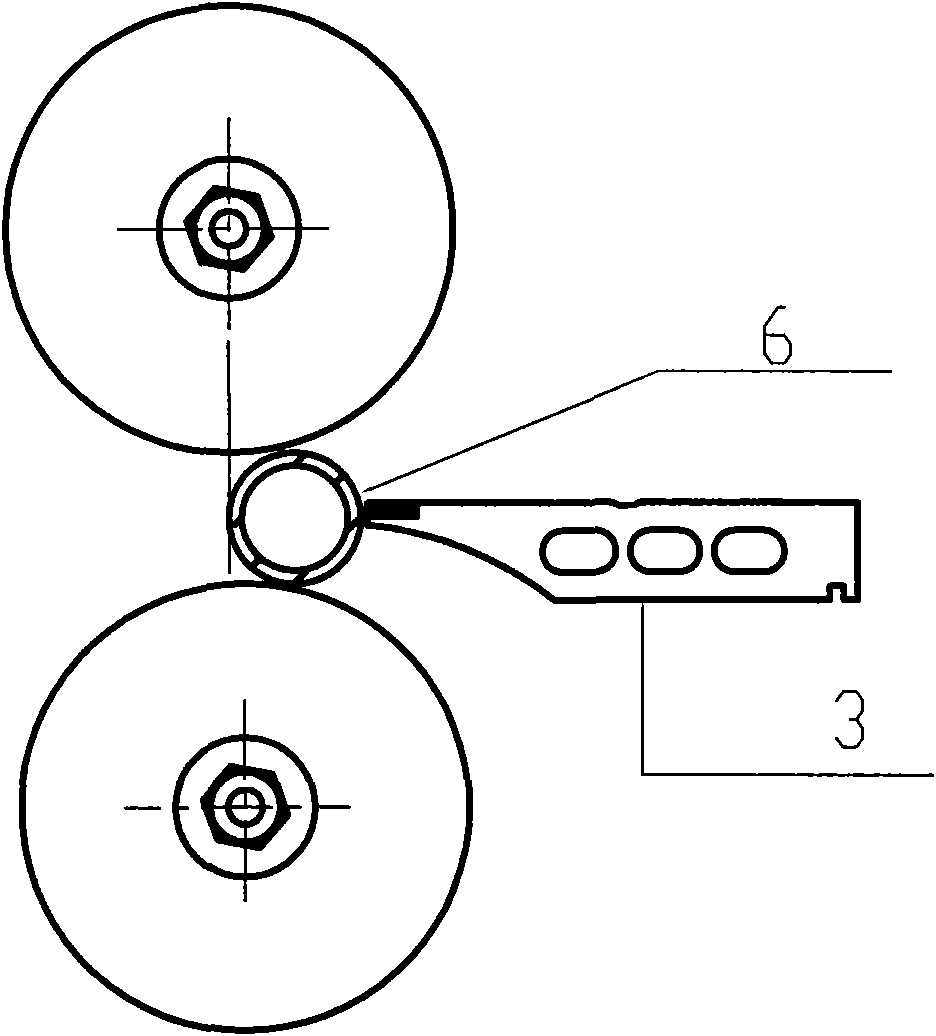

[0009] Miniature bearing five-point positioning ultra-precision support positioning mechanism, the workpiece is clamped by the upper and lower pressure rollers 1 and 2 to achieve up and down stability, and the rotation of the workpiece is realized by the motor driving the upper and lower pressure rollers. When installing, first Install the pressure roller, since the front and rear positions are fixed, you only need to determine the up and down positions, the up and down positions are just tangent to the outer circle of the workpiece, and the left and right are in the middle of the workpiece, but make sure to tilt to the right about 5-10 degrees, and then Install the pressure roller, because the upper and lower positions of the upper pressure roller are fixed, so it is only necessary to determine the front and rear positions of the upper pressure roller, that is, the center line of the upper pressure roller is tangent to the outer circle of the workpiece, but the direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com