Logistics conveying track bent rail device and manufacturing method thereof

A technology for conveying rails and rails, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of difficult to achieve precision requirements, low rail strength, and difficult to manufacture curved rails, and achieve rail stability and reliability. The effect of lifting, good curvature accuracy, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

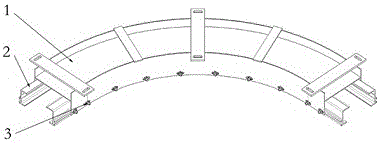

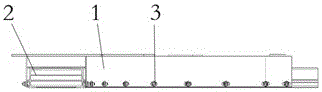

[0018] Such as Figure 1-2 As shown, the present invention comprises a fixed split track structure 1, a sub-section track 2 and a bolt connector 3. The logistics transportation track bending device includes a fixed split track structure 1, a sub-section track 2 installed on the fixed split track structure 1, and the sub-section track 2 is connected by bolts on a plurality of corresponding mounting holes evenly arranged. The parts 3 are aligned, twisted, and fastened so that they are close to the two inner curved surfaces of the fixed and split track structure 1.

[0019] The manufacturing method of the curved track device of the logistics transportation track of the present invention includes the manufacturing process steps of the sub-section track 2. The first step is to use laser cutting and other precision processing techniques to cut steel materials, assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com