Compression molding device and process of multi-curved-surface inorganic glass

A compression molding and inorganic glass technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of unfavorable optical properties of glass surface, increase of glass surface imprint defects, and prolonged bending time. The effects of glass bursting, guaranteed bending temperature, and guaranteed curvature accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

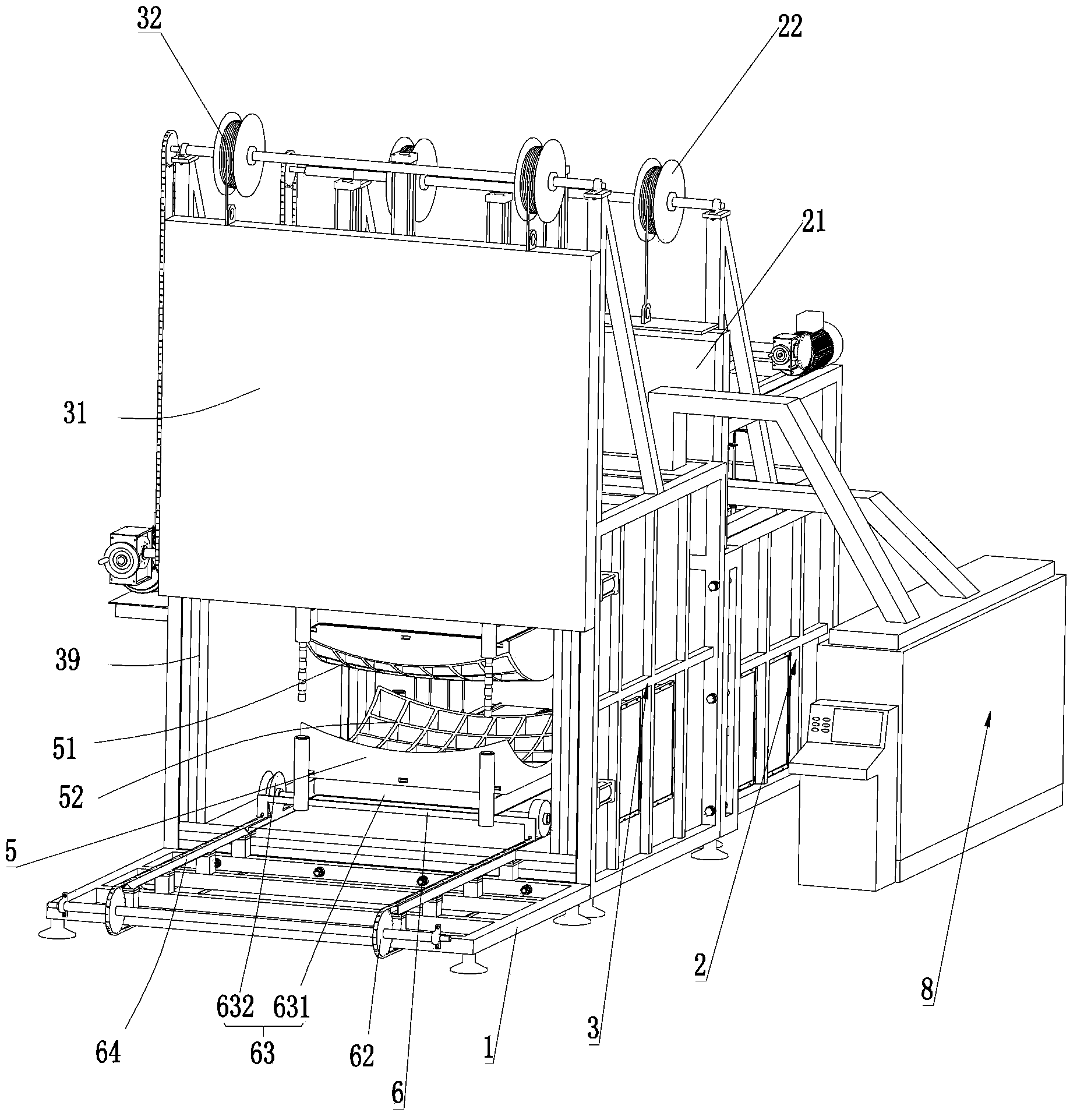

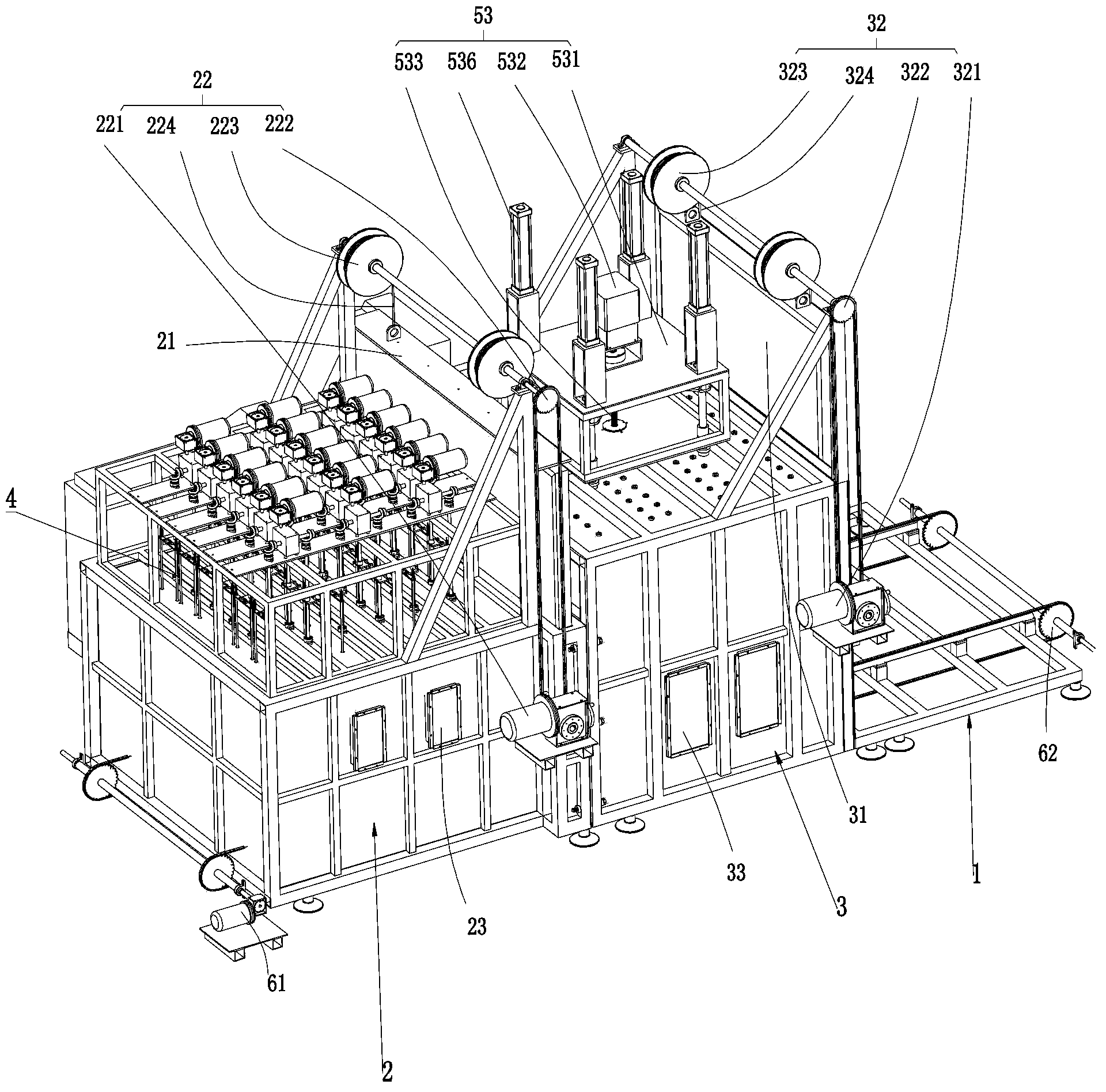

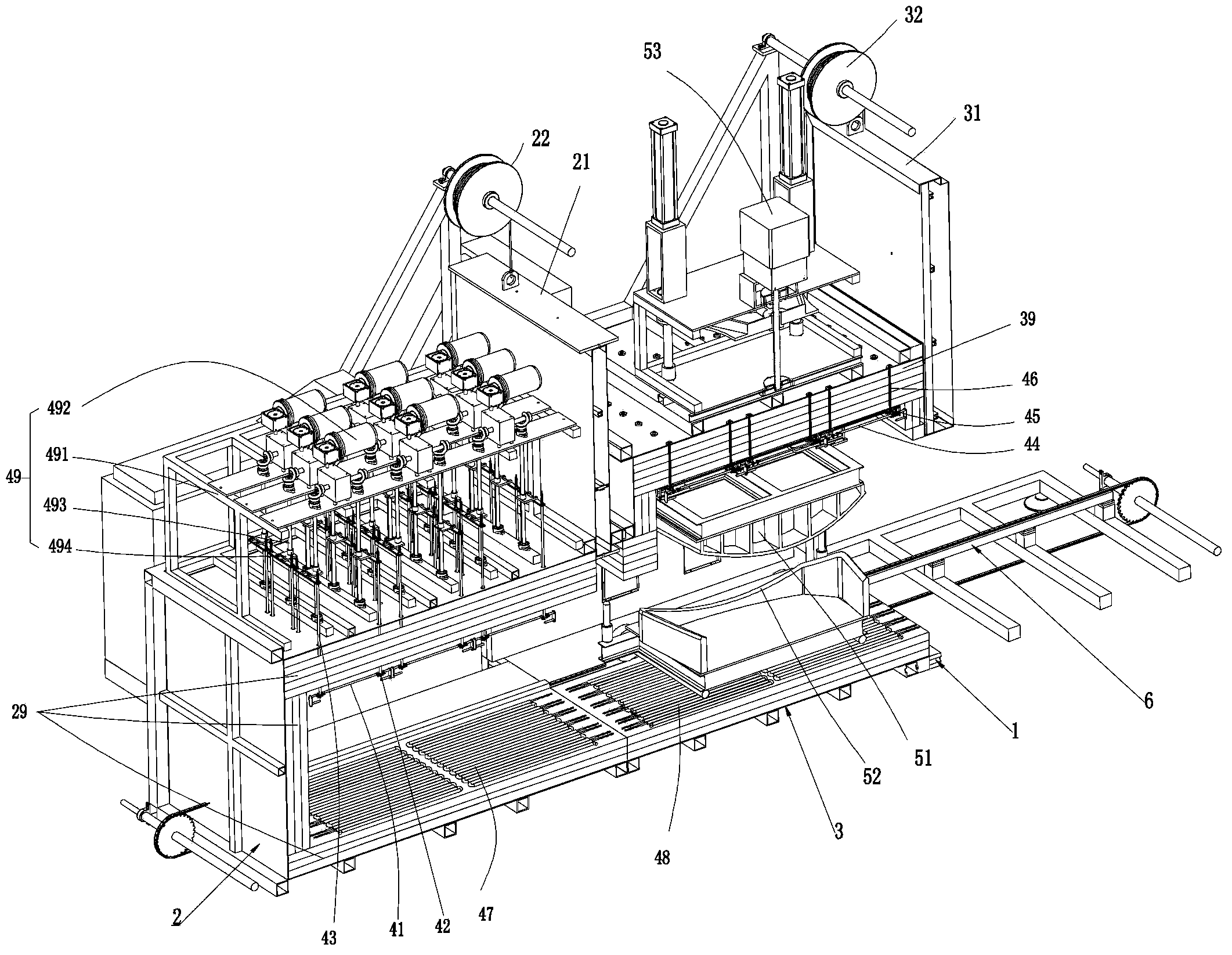

[0027] Such as Figures 1 to 3 As shown above, the embodiment of the present invention provides a molding equipment for multi-curved inorganic glass, which includes a support base 1, a heating box 2, and a molding box 3 for heating and heating the heating box 2 and the molding box 3 respectively. The heating device 4 of heat preservation, the molding die 5 that contains male mold 51, female mold 52 and male mold driving device 53, mold carrier 6, and the control box 8 that has equipment control system in it.

[0028] The heating box 2 is used to heat the inorganic glass fed into it to ensure and control the molding temperature of the inorganic glass. The heating box 2 is fixed on the support base 1 and is adjacent to the molding box 3 . The heating box 2 includes an inner door 21 and an inner door driving device 22 as a side wall of the heating box body, and the inner door 21 forms a square shape with a heating chamber together with the top wall, the bottom wall and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com