Double-circle polarization and difference beam broadband corrugation horn feed antenna

A dual circularly polarized, corrugated horn technology, used in waveguide horns, antennas, electrical components, etc., can solve the problems of difficult alignment of feeding points, unsatisfactory circular polarization axis ratio, etc., and achieve a good circular polarization axis ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

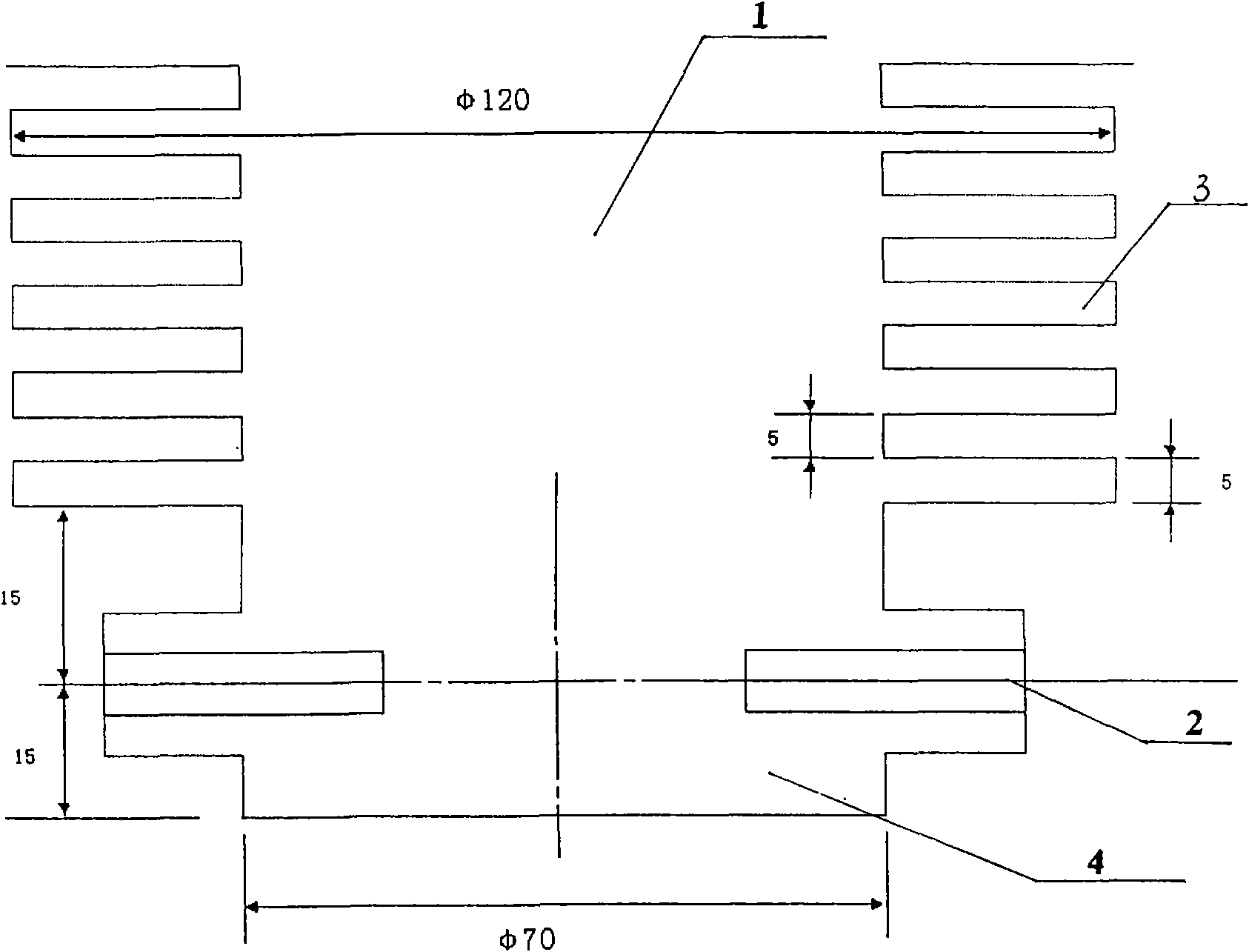

[0028] Now take the frequency 4.1GHz~6.9GHz feed antenna as an example to further illustrate the present invention, its center frequency is 5.5GHz, and its antenna size is shown in image 3 , see the measured lobe diagram Figure 4 ~ Figure 9 .

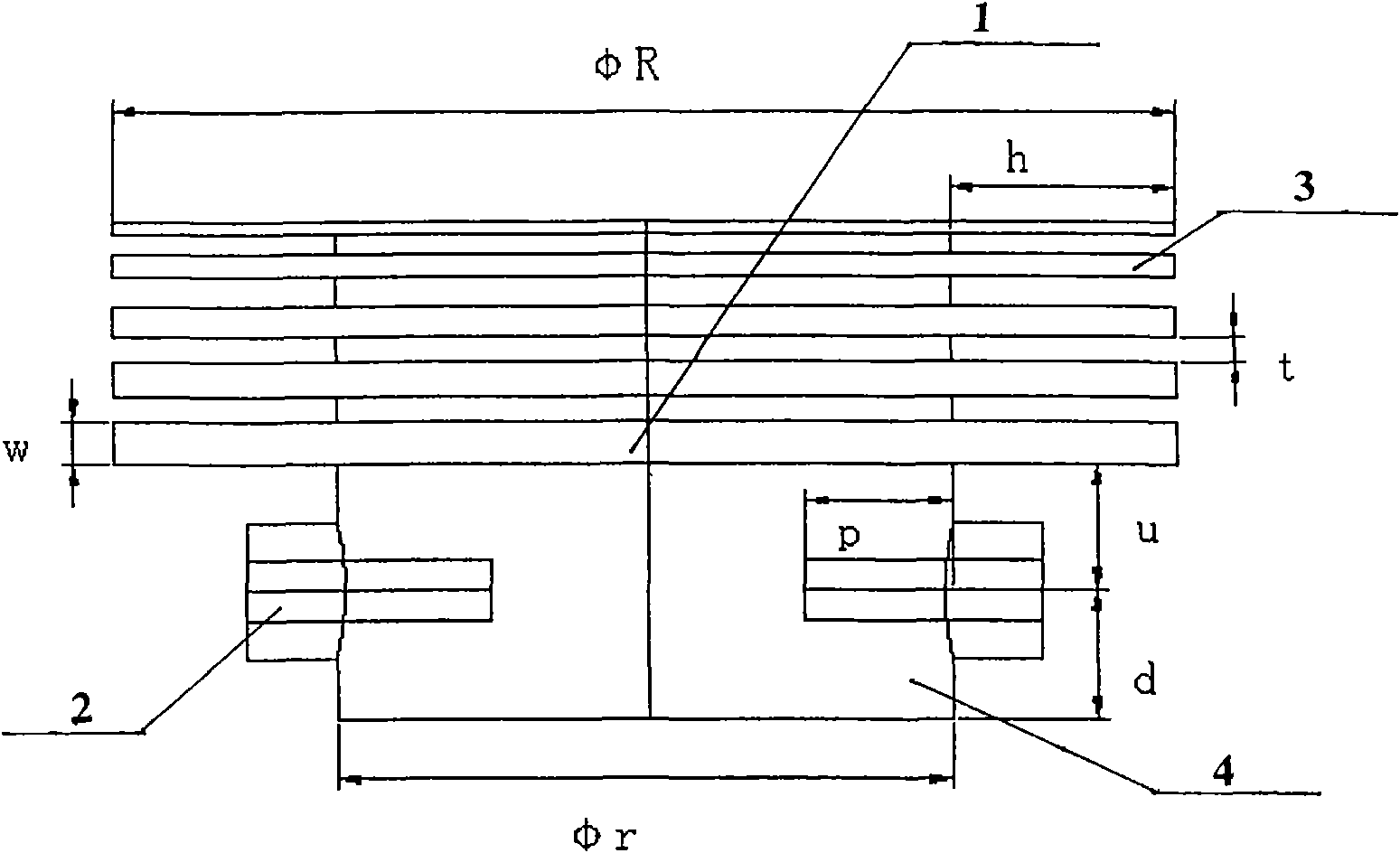

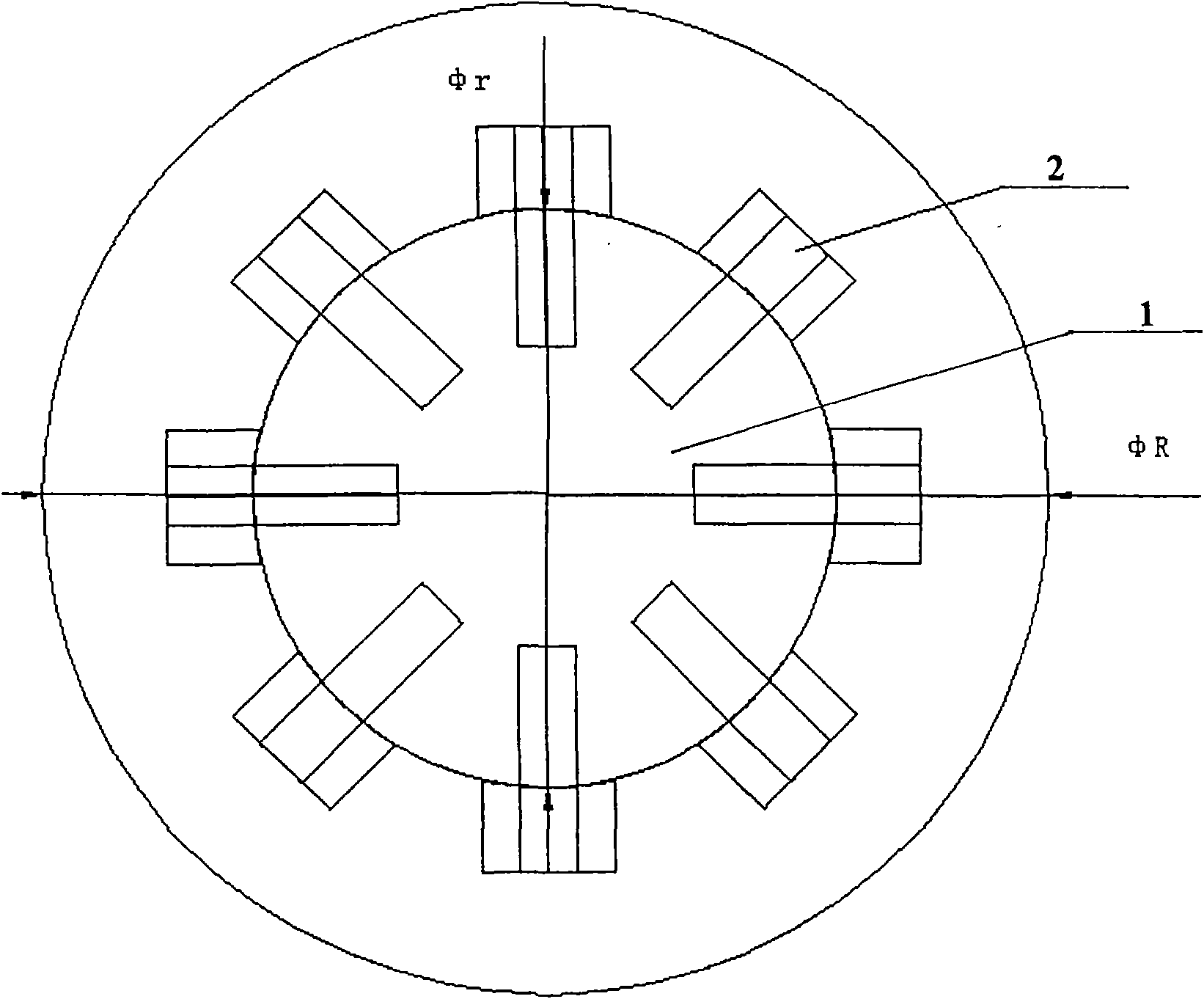

[0029] see figure 1 and figure 2 , the dual circular polarization and differential beam broadband corrugated horn feed antenna includes an antenna body 1 and a coaxial probe 2 . The antenna body 1 is cylindrical, the upper part is a corrugated part 3 , and the lower part is a feeding part 4 . The corrugated part of the upper part of the antenna body 1 is evenly distributed in the radial direction with five ring grooves, the groove depth of which is 1 / 4 wavelength of the center frequency, and the groove width and groove spacing are both less than 1 / 10 of the center frequency wavelength, respectively 5 mm ; And the slot width w and the slot spacing t are equidistant; the diameter of the corrugated part of the antenna body 1 is 120...

Embodiment 2

[0032] see figure 1 , the groove width w and the groove spacing t of the corrugated part of the present invention can also be gradually changed, which is determined according to the bandwidth requirement. Its feed part adopts six coaxial probes to feed power.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com