Constant tension micro-compensation trolley device used for papermaking mechanical felt tensioning machine

A technology of papermaking machinery and tensioner, applied in the field of constant tension micro-compensation trolley device, which can solve problems such as paper defects, easily damaged felt, and inability to perform felt length compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

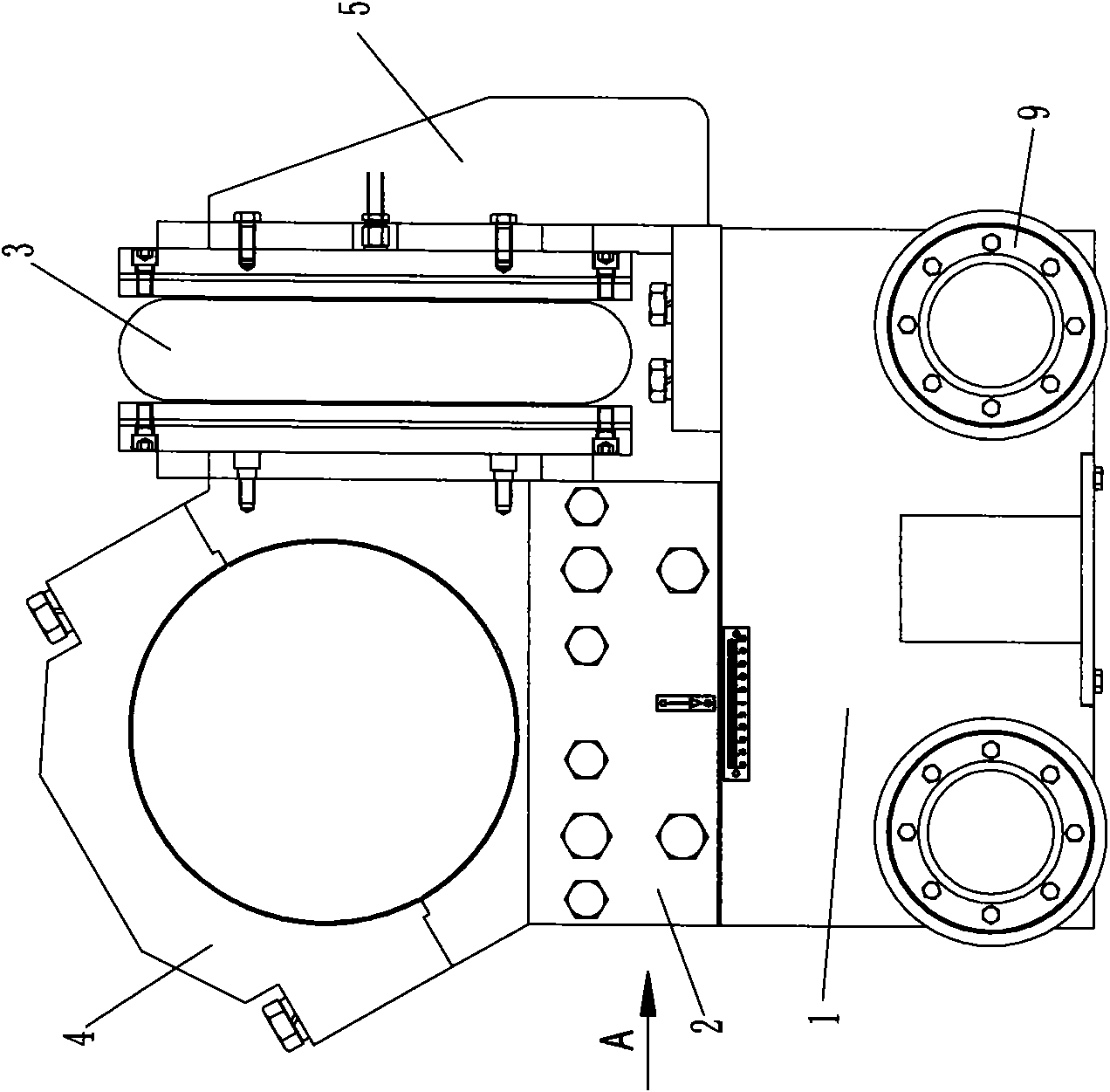

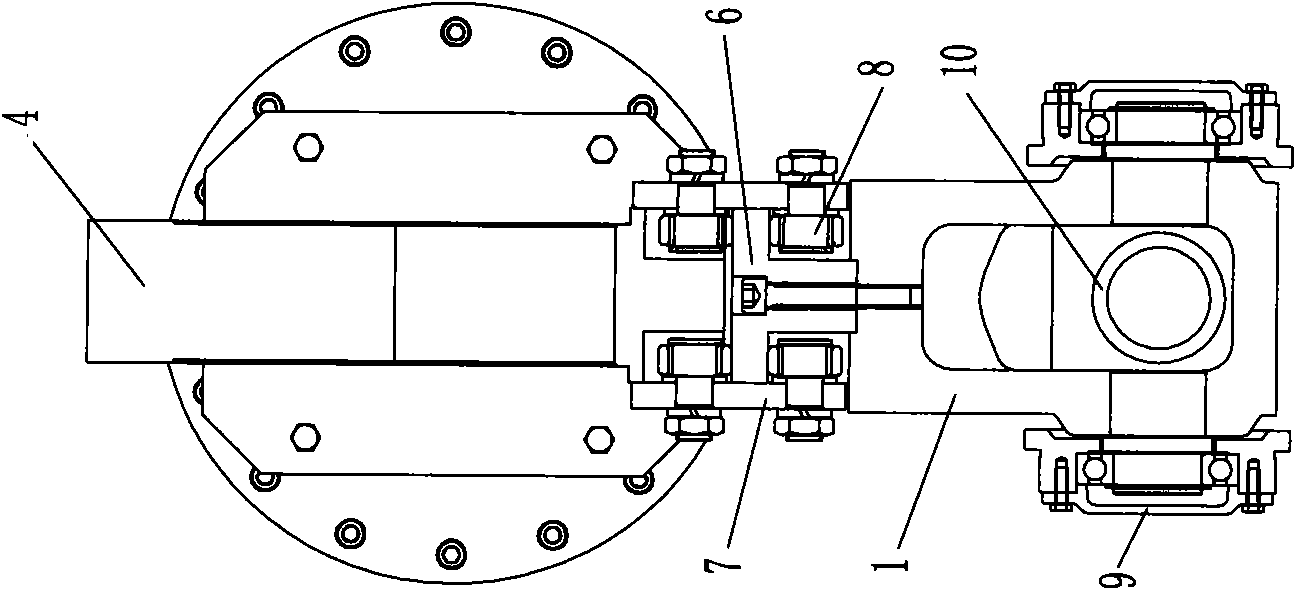

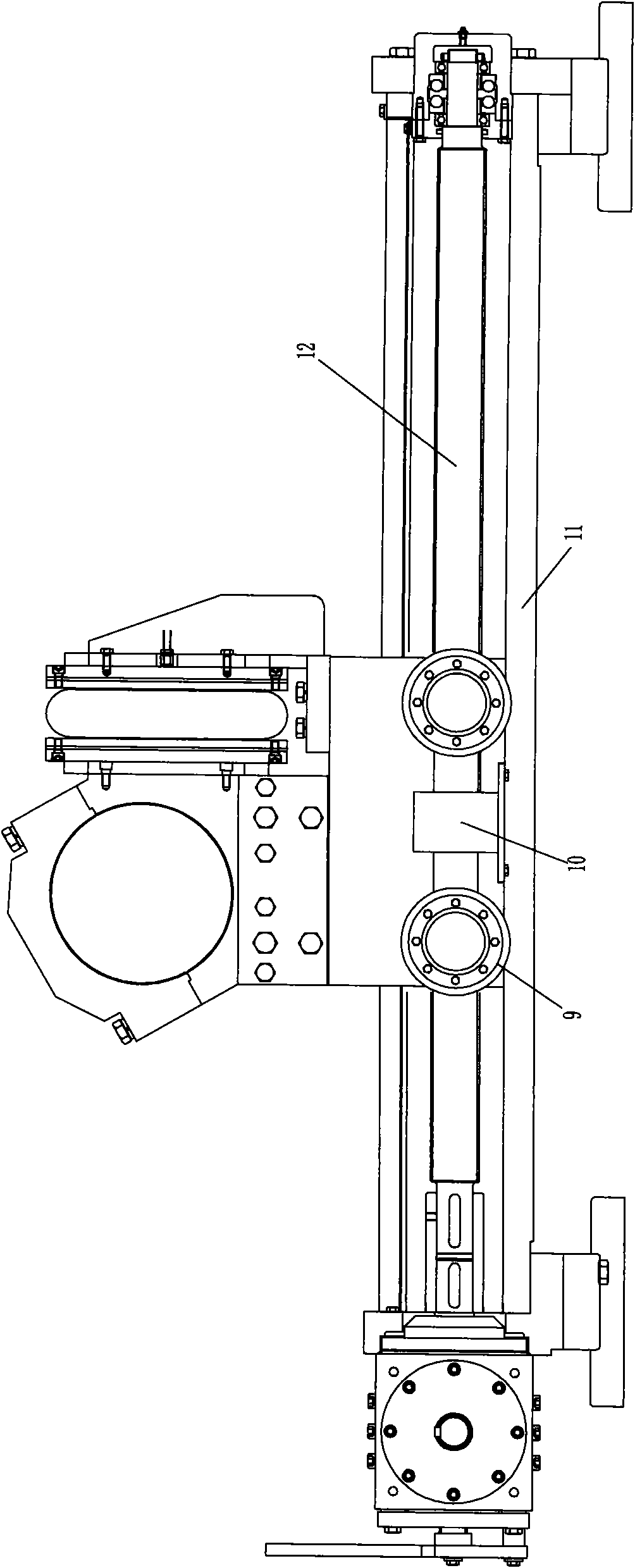

[0018] Embodiment: A constant tension micro-compensation trolley device for a felt tensioner of a papermaking machine, including a trolley 1, a slider 2 and a pneumatic tire 3, the trolley can be positioned and slid in a straight line on the guide rail of the felt tensioner, and the slider can be Do linear positioning sliding on the trolley, the trolley is parallel to the sliding direction of the slider, the upper part of the slider is fixed with a bearing seat 4 supporting the felt roller, one end of the pneumatic tire is fixed with the slider, and the other end of the pneumatic tire is fixed with the trolley. When the tire is inflated, it stretches to push the slider to slide (when the trolley device moves to a certain position, the felt has a certain tension, but at this time the tension is smaller than required, and the pneumatic tire starts to inflate, thereby pushing the slider and The bearing seat starts to move in a straight line relative to the trolley, and the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com