Integral type level oil extraction wellhead equipment

A wellhead device and integrated technology, applied in the field of integrated horizontal oil production wellhead devices, can solve the problems of bulky, increased platform construction costs, cumbersome and other problems, and achieve the effect of simplifying workover operations and saving installation and workover time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

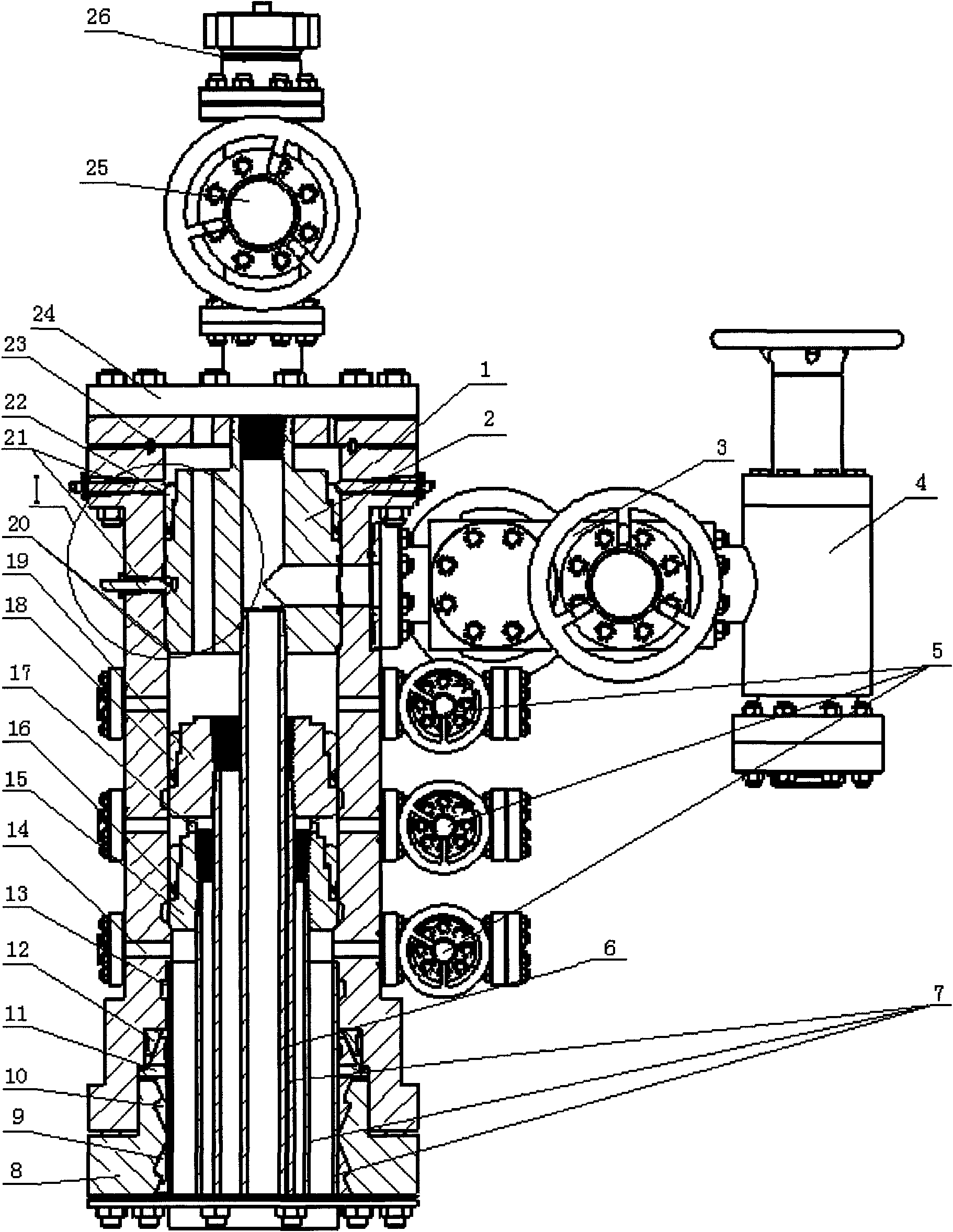

[0021] Embodiment 1: Taking an integral horizontal oil recovery wellhead device as an example, the invention is further described in detail.

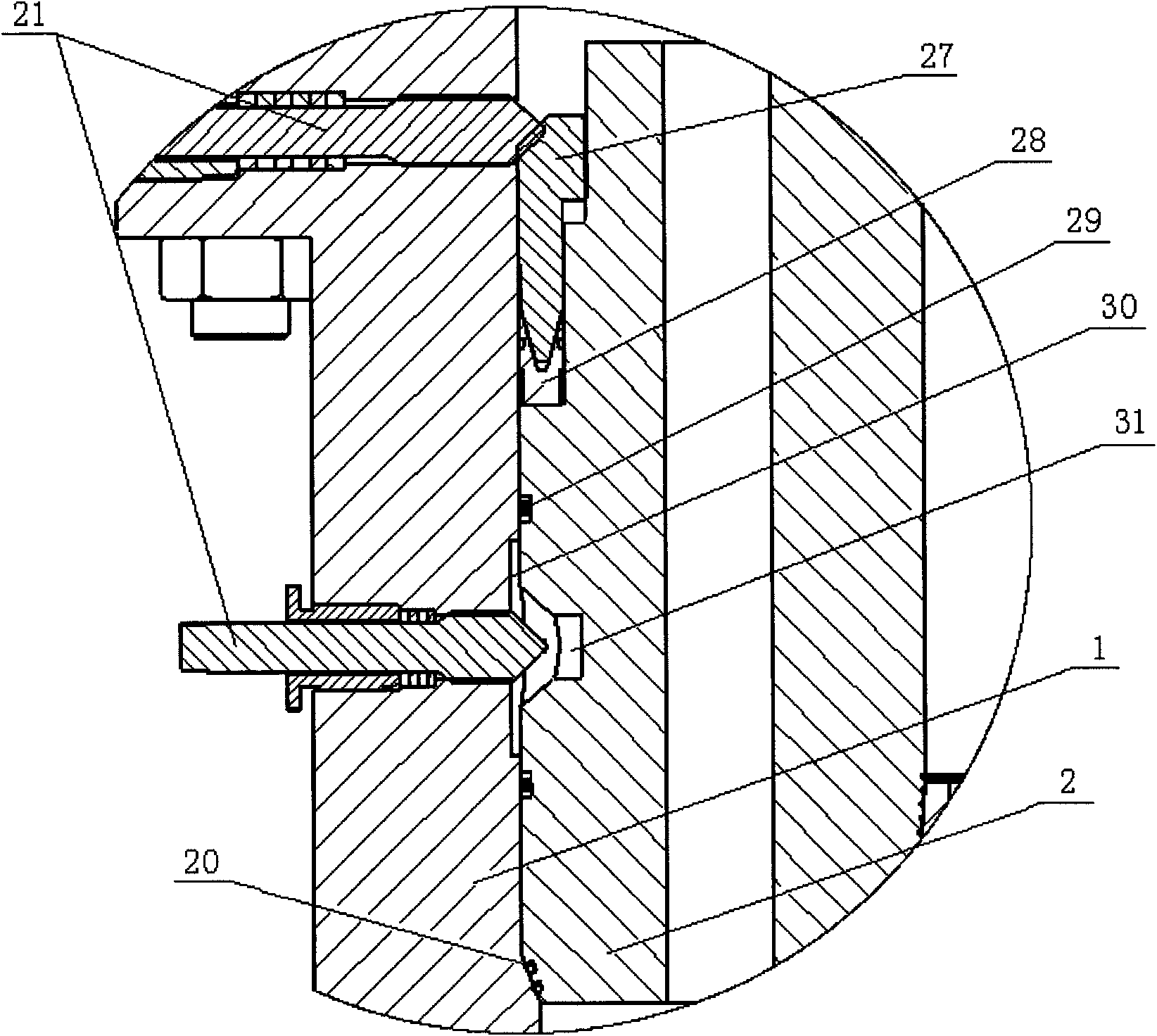

[0022] refer to figure 1 . The integral horizontal oil production wellhead device of the present invention consists of a wellhead body 1, a tubing hanger 2, a gas-hydraulic safety valve 3, a throttle valve 4, a flat valve 5, a WD casing hanger slip shell 8, and an anti-slip 9 , positive slip 10, sealing baffle 11, double C-shaped sealing ring 12, BT sealing ring 13, plug 14, casing hanger 15, 19, V-shaped metal seal 16, 18, 22, bimetallic hollow O-shaped Sealing ring 20, top wire assembly 21, steel ring 23, different diameter flange 24, cleaning wax valve 25, christmas tree cap 26 are formed.

[0023] The wellhead body 1 is cylindrical and has an upper cavity, a middle cavity and a lower cavity in the wellhead body 1 . The upper cavity and the middle cavity are cylindrical cavities, and the lower ends of the upper cavity and the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com