Support and alignment method for inhibiting large mirror astigmatic deformation

An installation and adjustment method and astigmatism technology, applied in the direction of installation, mirrors, measuring devices, etc., can solve the problems of complex support and adjustment measures, large amount and difficulty of analyzing data, and difficulty in correcting deformation errors, etc., to achieve the wavefront of the optical system Fast convergence of distortion error, easy implementation, and the effect of suppressing astigmatic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

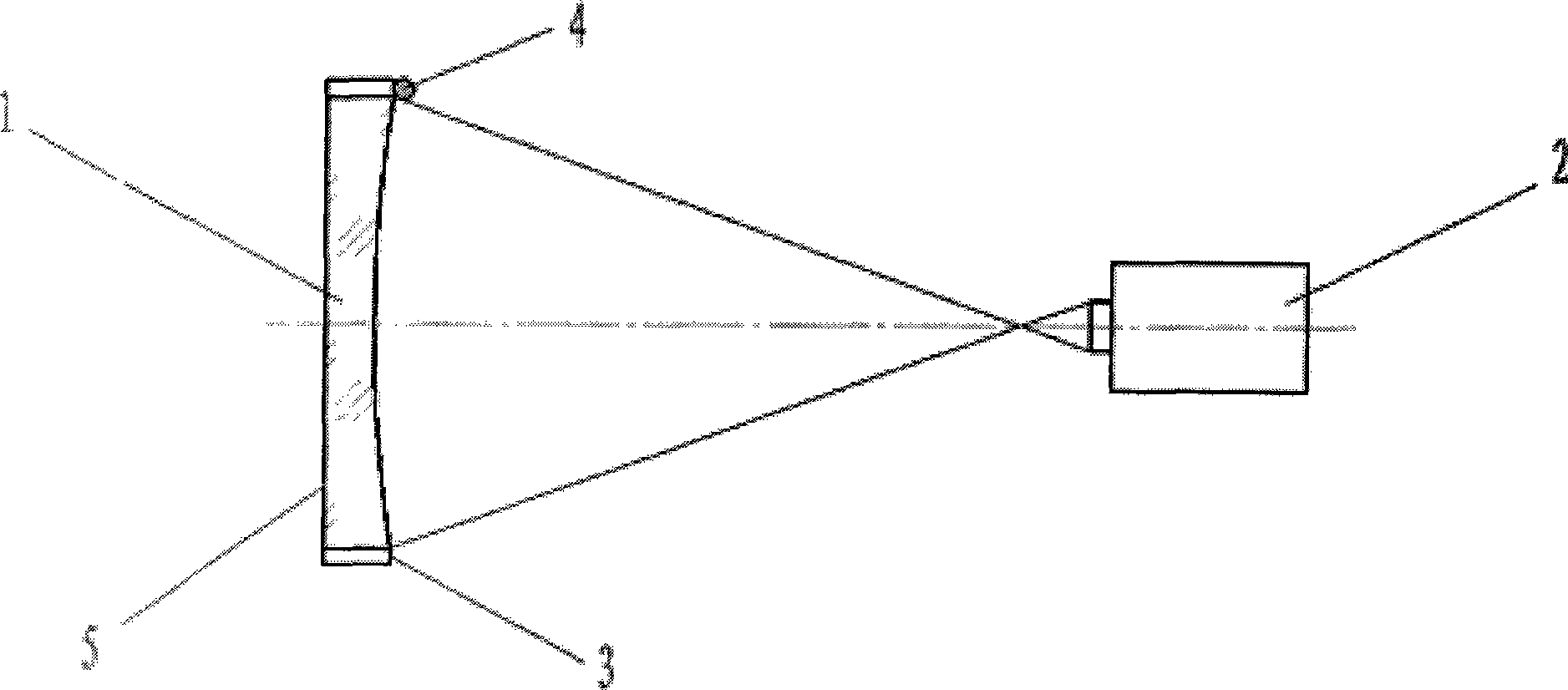

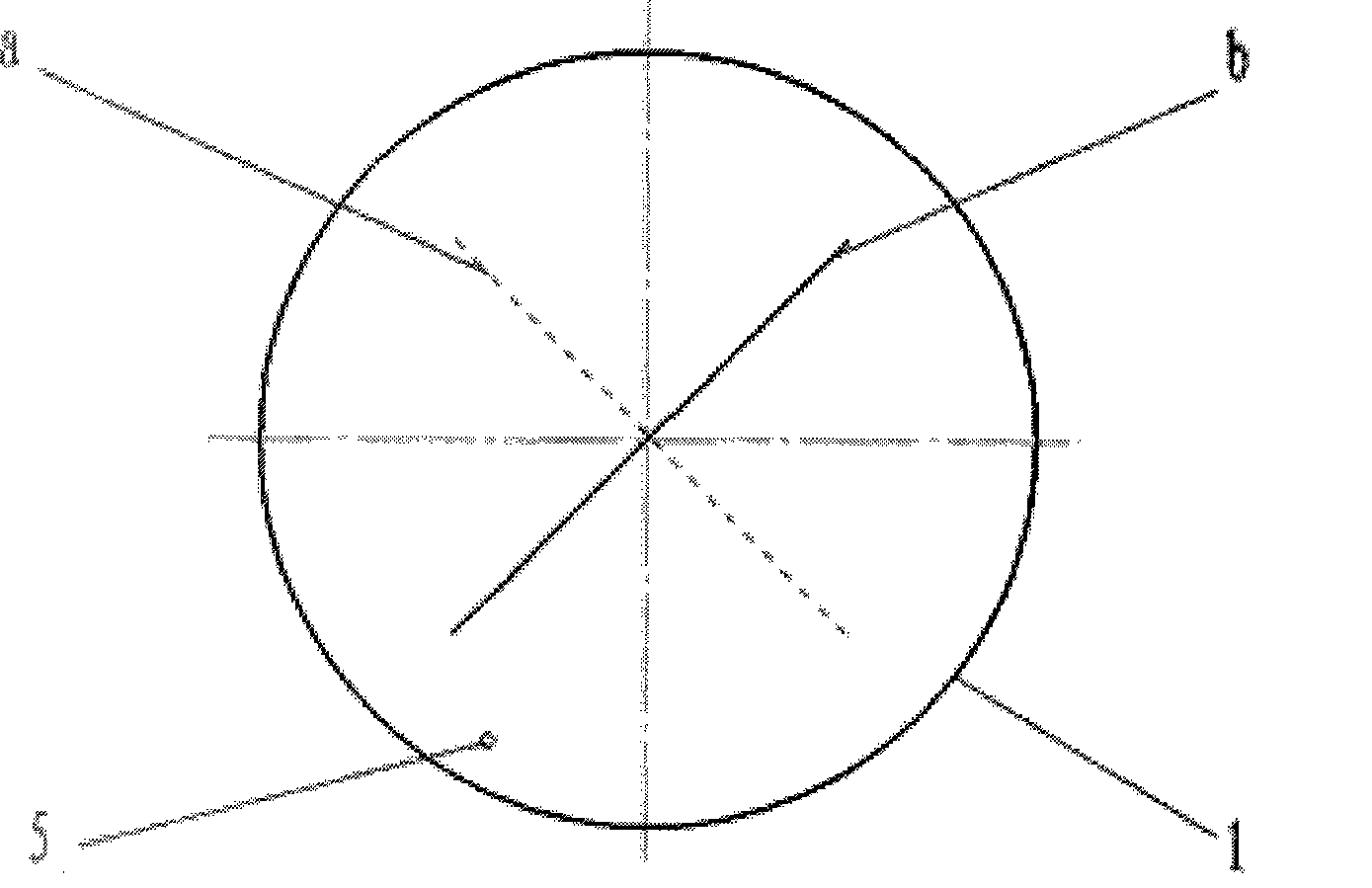

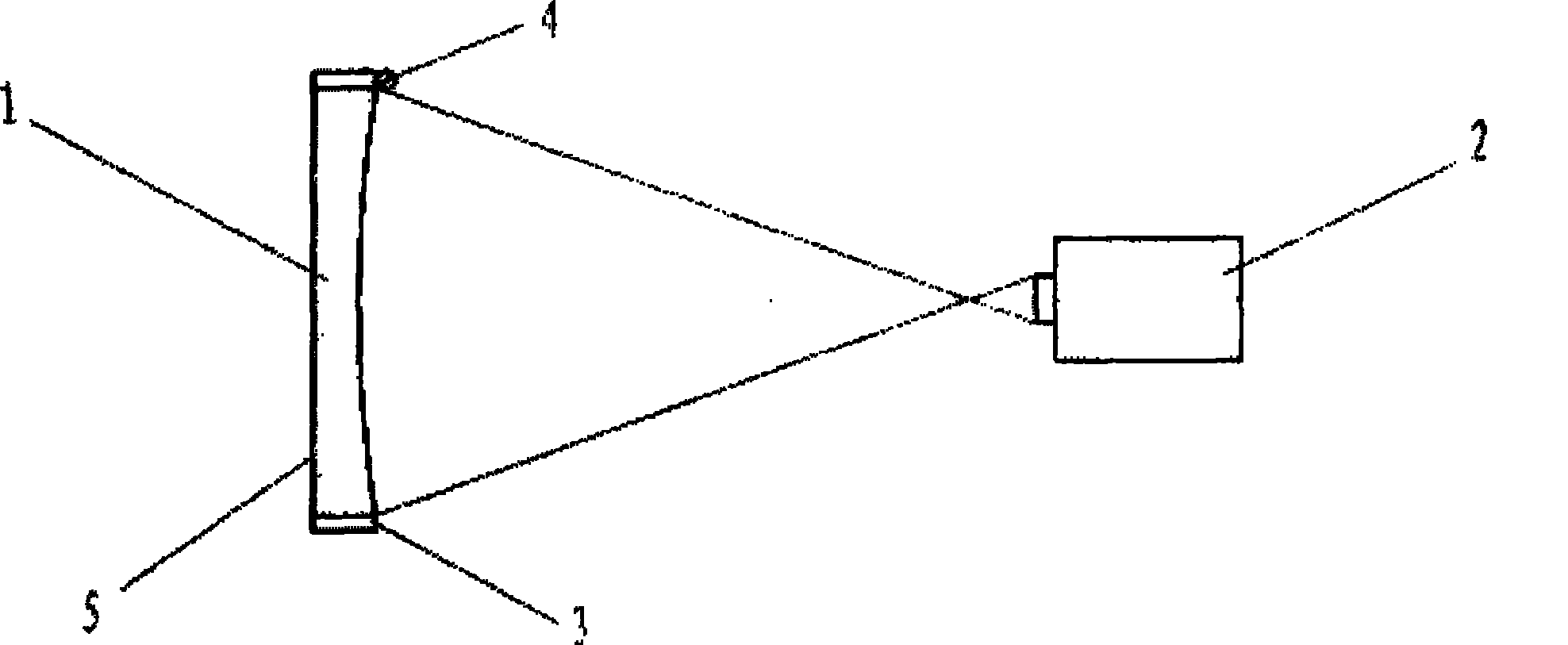

[0032] The principle of the present invention: the optical system with the large mirror as the main reflector, the astigmatic aberration that still exists after conventional installation is usually mainly caused by the deformation of the large mirror itself, then, the image obtained by analyzing the wavefront distortion measurement results of the optical system The direction of astigmatism, or the direction of astigmatism obtained by directly measuring the wavefront distortion of the large mirror, is directly related to the deformation direction of the large mirror itself. Any optical material can be regarded as an elastic body when analyzing its surface deformation, and its mechanical deformation relationship satisfies the generalized Hooke's law. The results of optical interferometry can characterize the distortion of the laser wavefront after being reflected by the large mirror, and the distortion of the laser wavefront can indirectly represent the surface shape change of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com