Side guard plate

A technology for side guards and mainboards, applied in furniture parts, applications, household appliances, etc., can solve the problems of unstable assembly connection, complicated operation, and the overall appearance is not beautiful, so as to achieve flexible and diverse assembly structures, expand the scope of use, and have a beautiful appearance. and concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

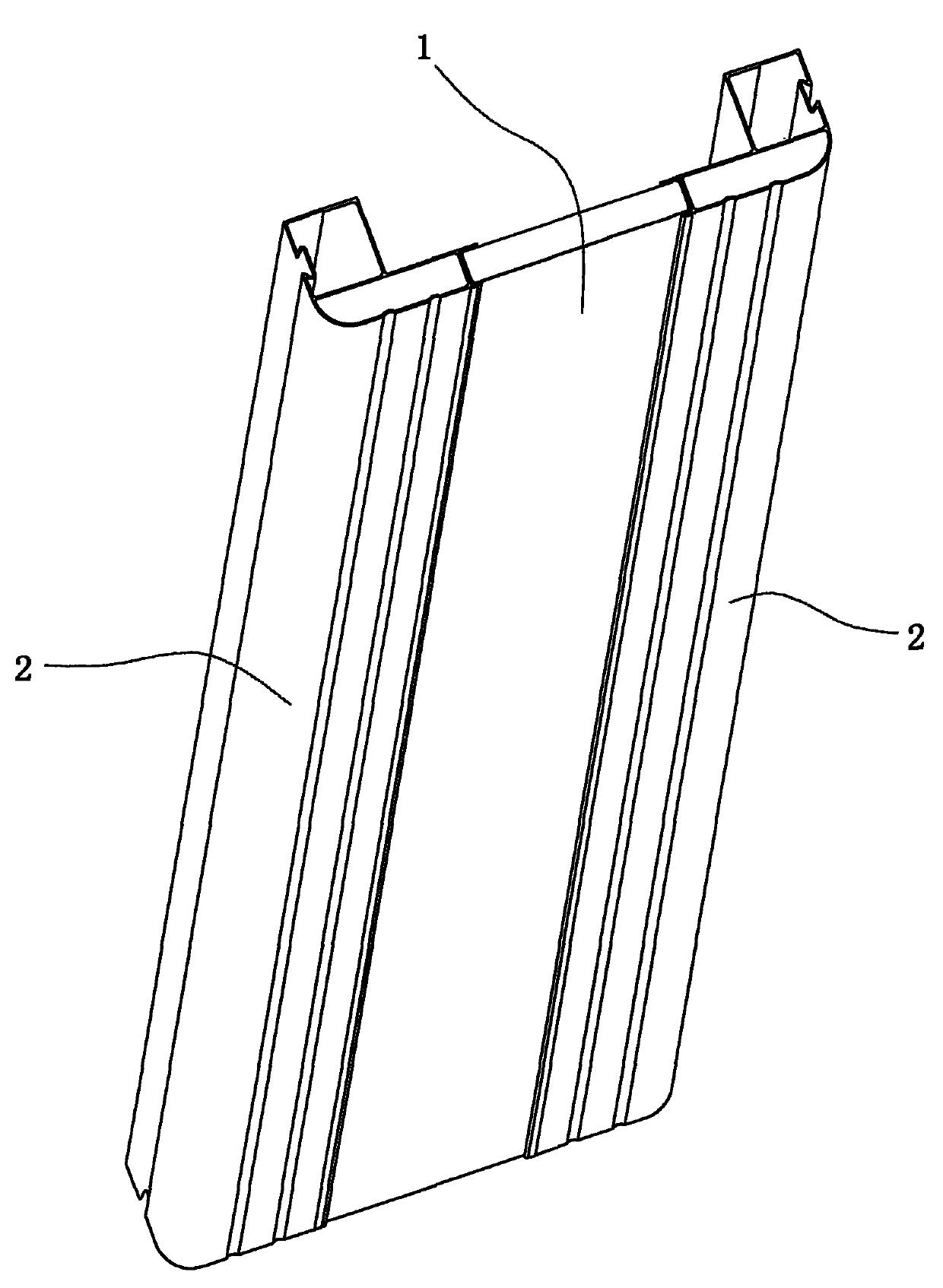

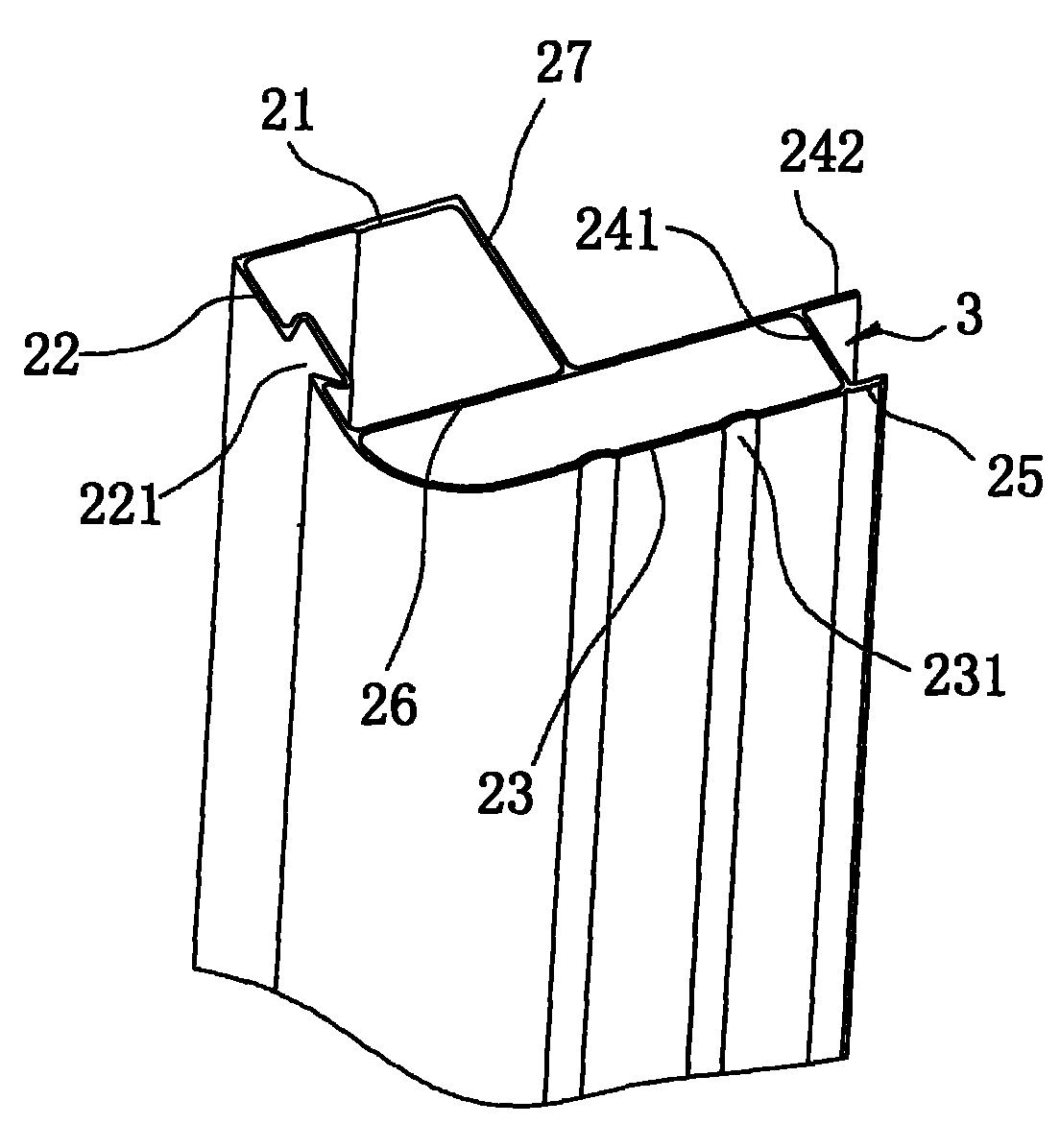

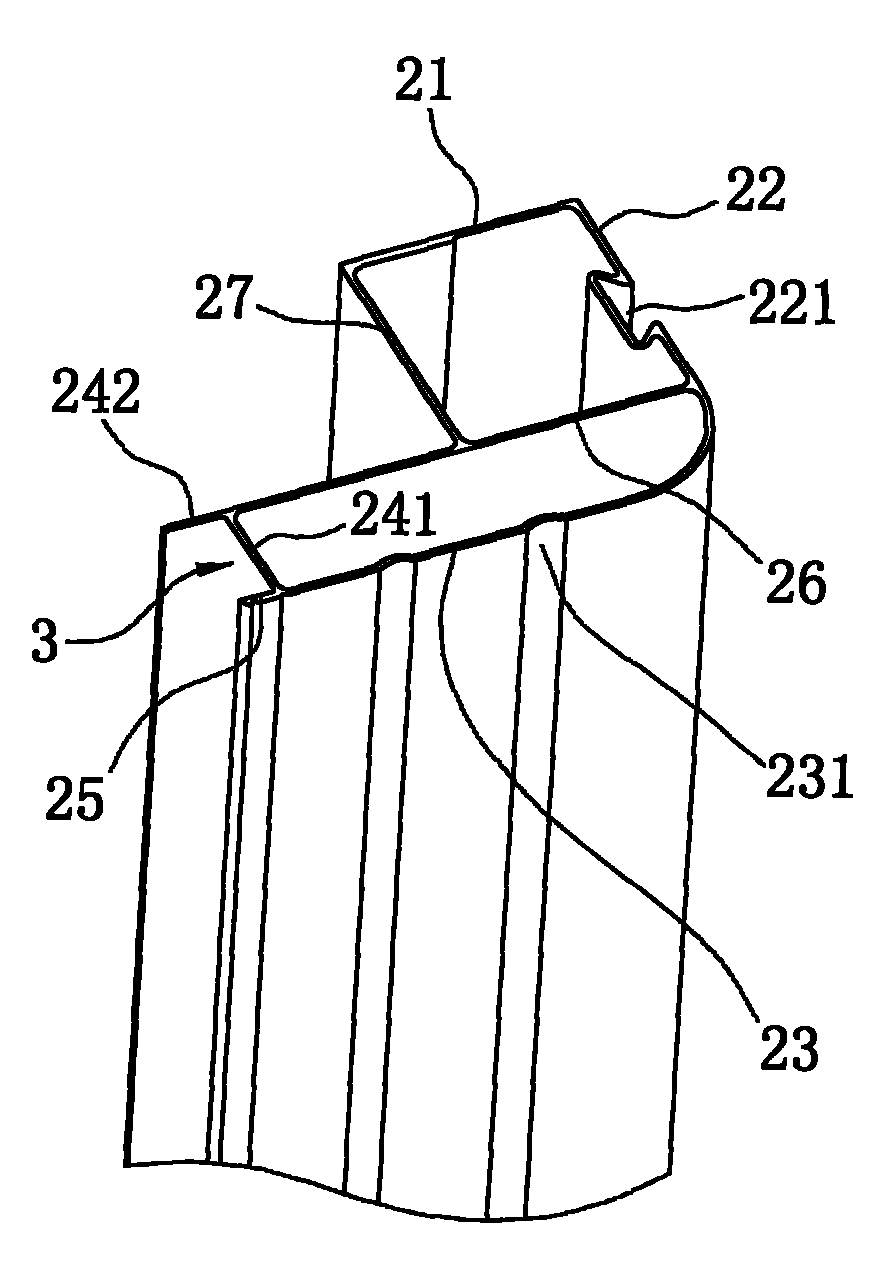

[0017] like Figure 1 ~ Figure 4 As shown, it is a specific embodiment of the present invention. The side guard includes a rectangular main board 1 and side posts 2 connected to both sides of the main board. The side posts 2 include a first side 21 integrally formed by die casting, a second The two sides 22 and the third side 23, the first side 21, the second side 22 and the third side 23 form a columnar structure that is arranged transversely and is U-shaped in section, and the longitudinal direction of the third side 23 The edge is bent toward the first side 21 to form an L-shaped flange 24, and the joint portion of the side and the back of the main board 1 abuts against the L-shaped flange 24 connected to the corresponding side, so that the main board 1 and the two side columns 2 are integrated into one piece ;

[0018] Wherein, the posit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap