Bi-component valve

A two-component, valve body technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of easy wear of the sealing ring gasket, slow dispensing speed, inconvenience, etc., to achieve the sealing structure is not easily damaged, functional Diversified, clean glue break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

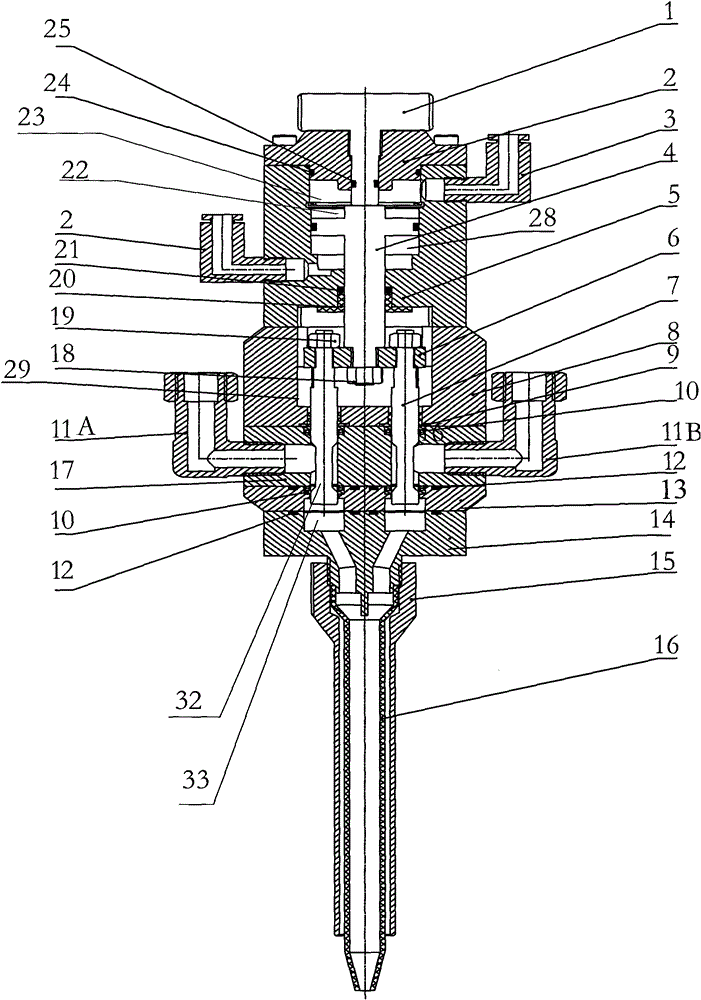

[0028] Such as figure 1 as shown,

[0029] A two-component valve, a valve body includes an upper valve body 5 and a lower valve body 18, the head of the upper valve body 5 is provided with an adjustment knob 1, and a cylinder 28, the A cavity 29 is set in the middle of the lower valve body 18, a first channel 20 is set between the cylinder 22 and the cavity 29, and at least one glue outlet hole is set at the bottom of the lower valve body 18, and the glue outlet hole and the The cavity 29 is connected; as required, one, two, three or even more glue outlet holes can be set. In this embodiment, two glue outlet holes are provided, namely the first glue outlet hole 33 and the The second glue hole.

[0030] A first piston 4, the head of the first piston 4 is a cross-shaped head, the cross-shaped head is arranged in the cylinder 22, and the cross-shaped head is connected with the adjusting knob 1 , the middle part of the first piston 4 is set in the first channel 20, the tail of ...

Embodiment 2

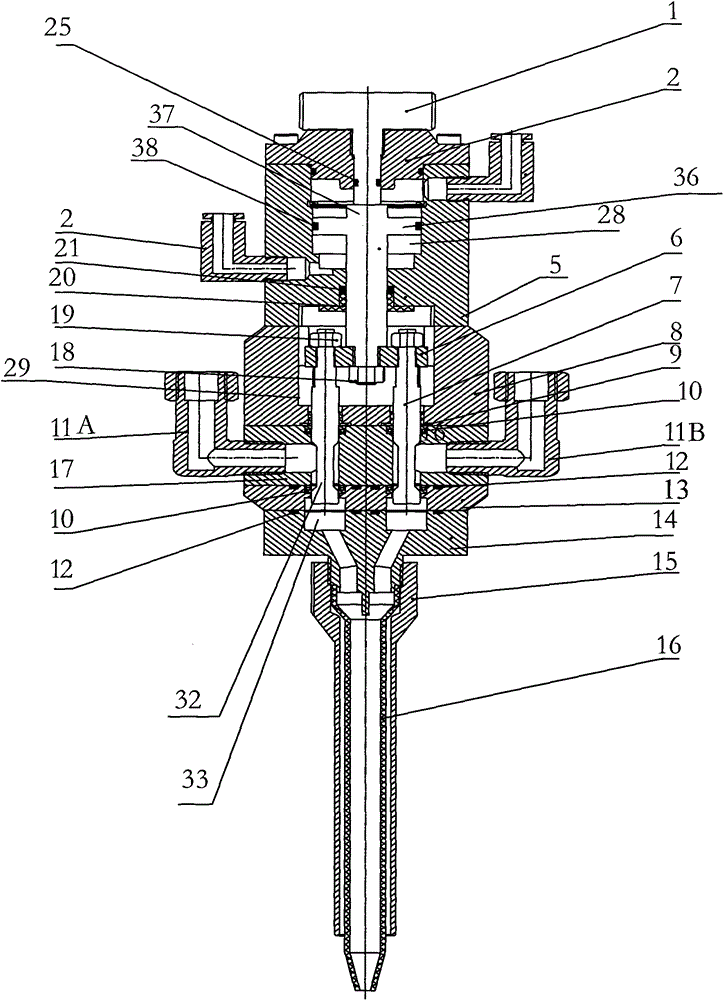

[0039] Such as figure 1, figure 2 as shown,

[0040] In the process of daily use, the two-component valve is usually installed on the fixed end of the glue dispensing machine or manipulator or robot to complete the glue spraying process. First, adjust the head adjustment knob 1 set on the upper valve body 5 to make the upper valve The size of the volume of the cylinder 28 in the body 5 meets the needs of the first piston 4 to move up and down. The head of the first piston 4 is a cross-shaped head, and the cross-shaped head is arranged in the cylinder 22. The upper side of the upper valve body 5 is provided with a first air inlet 2 and a second air inlet 3, which are distributed on both sides of the cross-shaped head, such as figure 2 As shown, more specifically, the cross-shaped head is composed of a horizontal part 36 and a vertical part 37, and the first air inlet 2 and the second air inlet 3 are respectively arranged on the upper valves on both sides of the cross-shaped...

Embodiment 3

[0044] Such as figure 1 , figure 2 Shown, in embodiment 1, do further explanation on the basis of embodiment 2, the diameter of the first glue outlet hole 33 in the present embodiment is different from the diameter of described second glue outlet hole; The second piston The diameter of the tail of the tail is different from the diameter of the tail of the third piston; according to the use of different glue ratios, the diameter of the first glue outlet 33 in the valve body is different from the diameter of the second glue outlet. And the diameter of the tail portion of the second piston and the diameter of the tail portion of the third piston are set according to a certain ratio, and the ratio of the diameter of the first glue outlet hole 33 to the diameter of the second glue outlet hole is, 1:2, 1:3, until 1:100, or the ratio of the diameter of the second glue outlet 33 to the diameter of the first glue outlet is 1:2, 1:3, until 1:100 , the diameter of the second glue outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com