Spraying valve

A valve body and nozzle technology, which is applied to coatings, devices that apply liquid to the surface, etc., can solve the problems of easy wear of the sealing ring gasket, slow dispensing speed, inconvenience, etc., so that the sealing structure is not easy to be damaged, and the function is better. Diversified, fast dispensing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

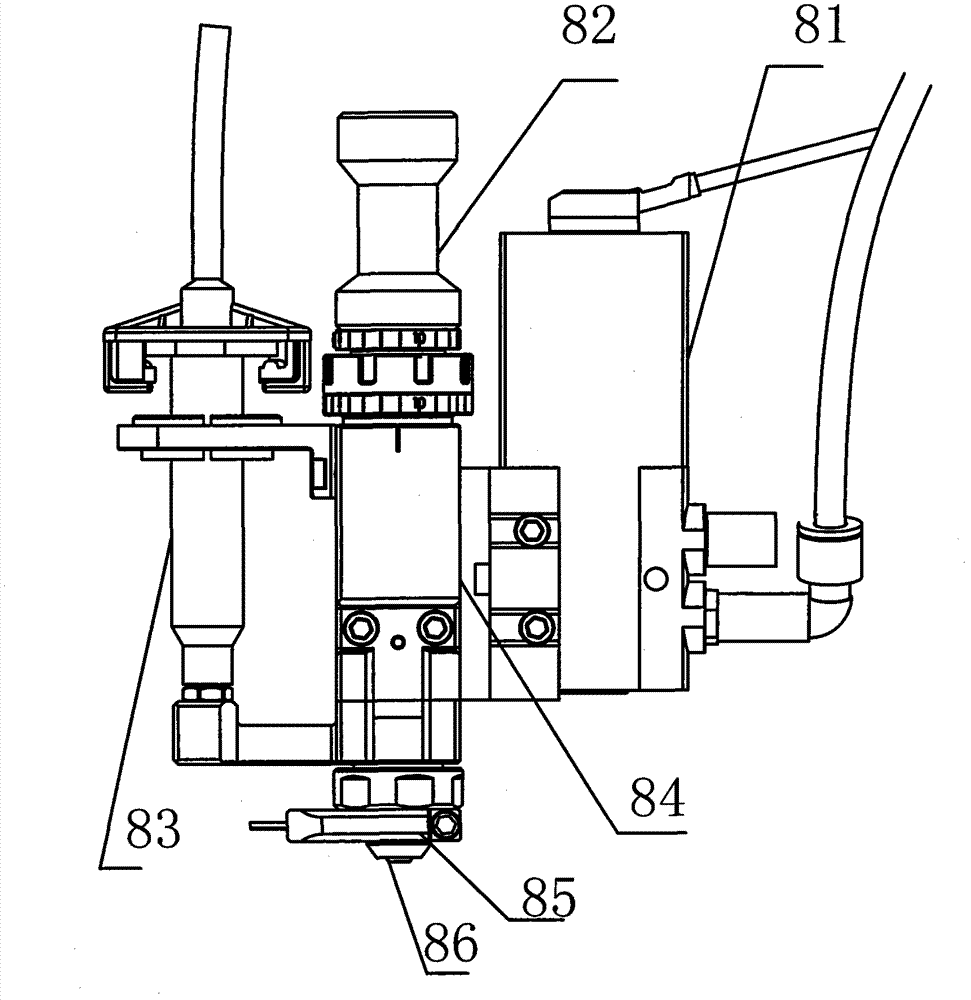

[0022] Such as figure 1 , figure 2 As shown in , a spraying valve includes a main valve body, a stroke adjustment device 82 arranged on the upper part of the main valve body, a feeding device 83 arranged on the side of the first body of the main valve body, and arranged on the side of the main valve body. The solenoid valve 81 on the second body side of the main valve body, a heating device 85 is arranged at the bottom of the main valve body, and a shower head 86 is arranged directly below the heating device 85;

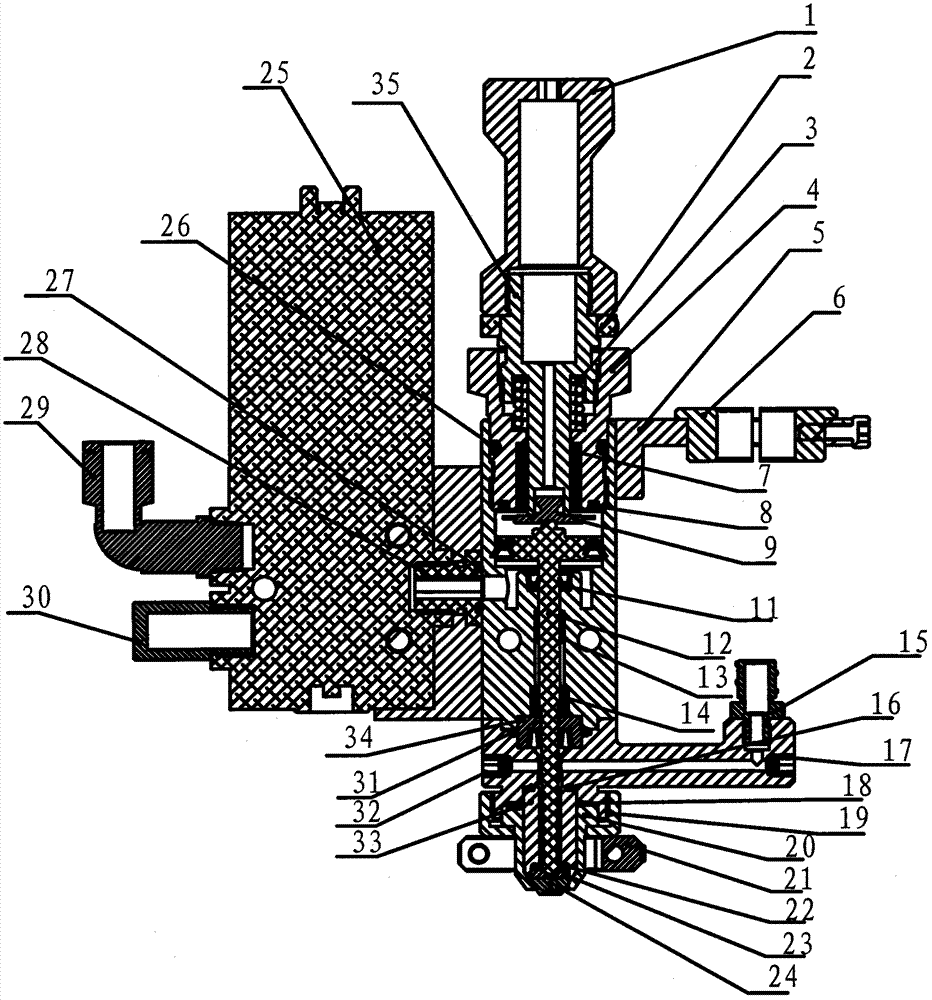

[0023] The main valve body includes an upper valve body 26 and a lower valve body 31, the upper valve body 26 and the lower valve body 31 are connected by a fixing device, the upper valve body is provided with a first body cavity, and the head of a striker assembly 12 Arranged in the first body cavity, the middle part of the striker assembly 12 runs through the entire lower valve body, and the tail of the striker assembly 12 fits with the spray head arranged below ...

Embodiment 2

[0035] Such as figure 1 , figure 2 , as shown, on the basis of the above-mentioned implementation examples, the spray valve is usually used in conjunction with a glue dispenser or a desktop robot or a manipulator or other glue dispensing devices.

[0036] In the process of daily use, the spray valve is usually installed on the fixed end of the dispenser or the manipulator or the robot to complete the glue spraying process. In this example, as figure 1 , figure 2 The main valve body of a spraying valve is installed on the manipulator end of the dispensing robot, the stroke adjustment device 82 is arranged on the upper part of the main valve body, the feeding device 83 is arranged on the side of the first body of the main valve, and is arranged on the The solenoid valve 81 on the side of the second body of the main valve, a heating device 85 is arranged on the lower part of the main valve body, and a nozzle 86 is arranged directly below the heating device;

[0037] The main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com