Silicone filling head

A filling head and silicone grease technology, which is applied in the field of dispensing machines, can solve problems such as uncontrollable silicone grease filling volume, and achieve the effects of improved pass rate and quality, uniform filling, and clean glue breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The silicone grease filling head of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples:

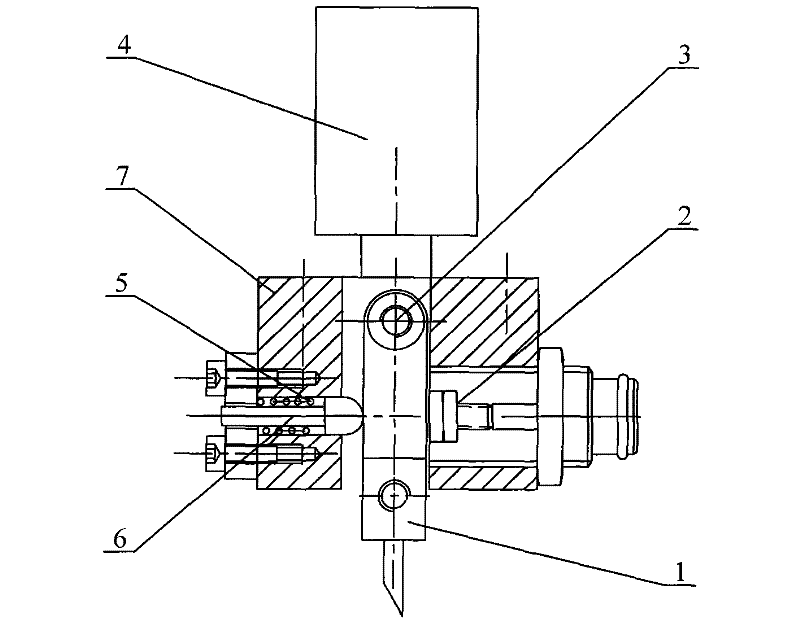

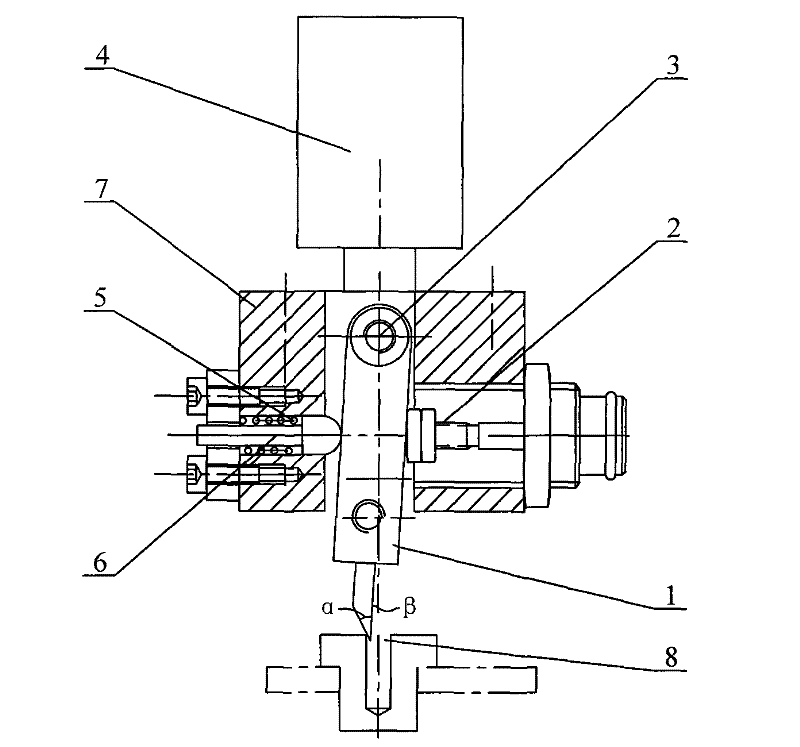

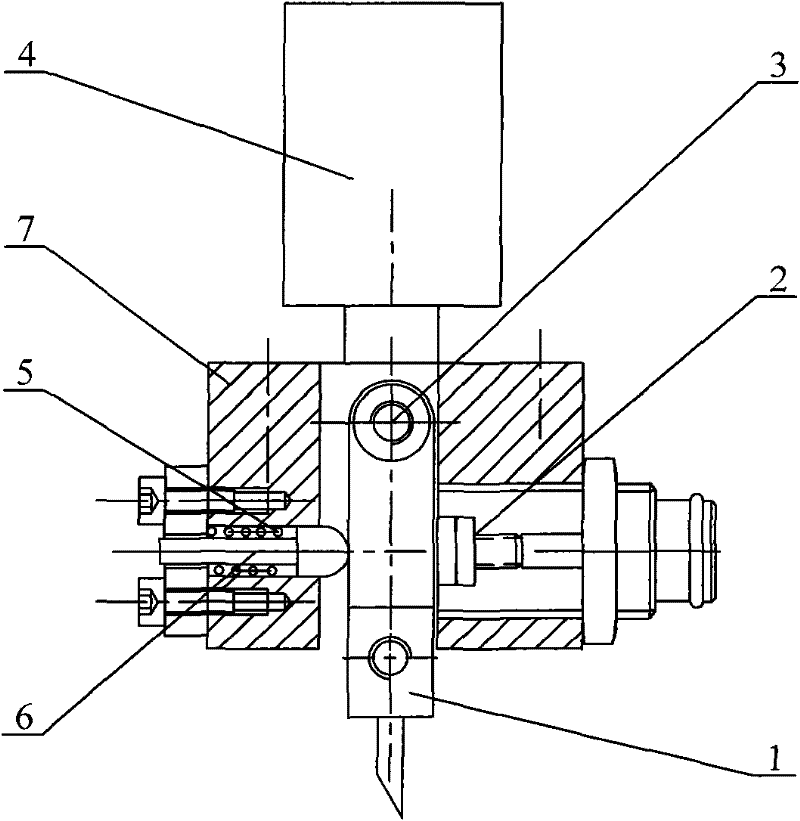

[0016] Such as figure 1 As shown, the silicone grease filling head of the present invention includes a filling needle 1 and a main cylinder 4 for driving the filling needle 1 to enter and exit the hole 8 of the part to be filled. The end of the piston rod of the main cylinder 4 is provided with a connecting block 7, and the afterbody of the filling needle 1 is hinged in the through hole vertically provided on the connecting block 7. The connecting fast 7 is also horizontally provided with a filling needle swing mechanism, which is used to drive the filling needle 1 to swing around its hinge shaft 3 . The filling needle swing mechanism in this embodiment includes a small air cylinder 2 and a push rod 6 arranged horizontally on both sides of the through hole of the connecting block 7 .

[0017] The pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com