Automatic dispensing machine for bonding bipolar plate of proton exchange membrane fuel cell

A technology of proton exchange membrane and fuel cell, which is applied to the device and coating of the surface coating liquid, which can solve the problems of many parts, complex structure of dispensing machine, large floor space, etc., to achieve enhanced suction force, Quick and clean glue breaking, stable and precise dispensing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is a specific embodiment of the present invention and a further description of the technical solutions of the present invention, but the present invention is not limited to these embodiments.

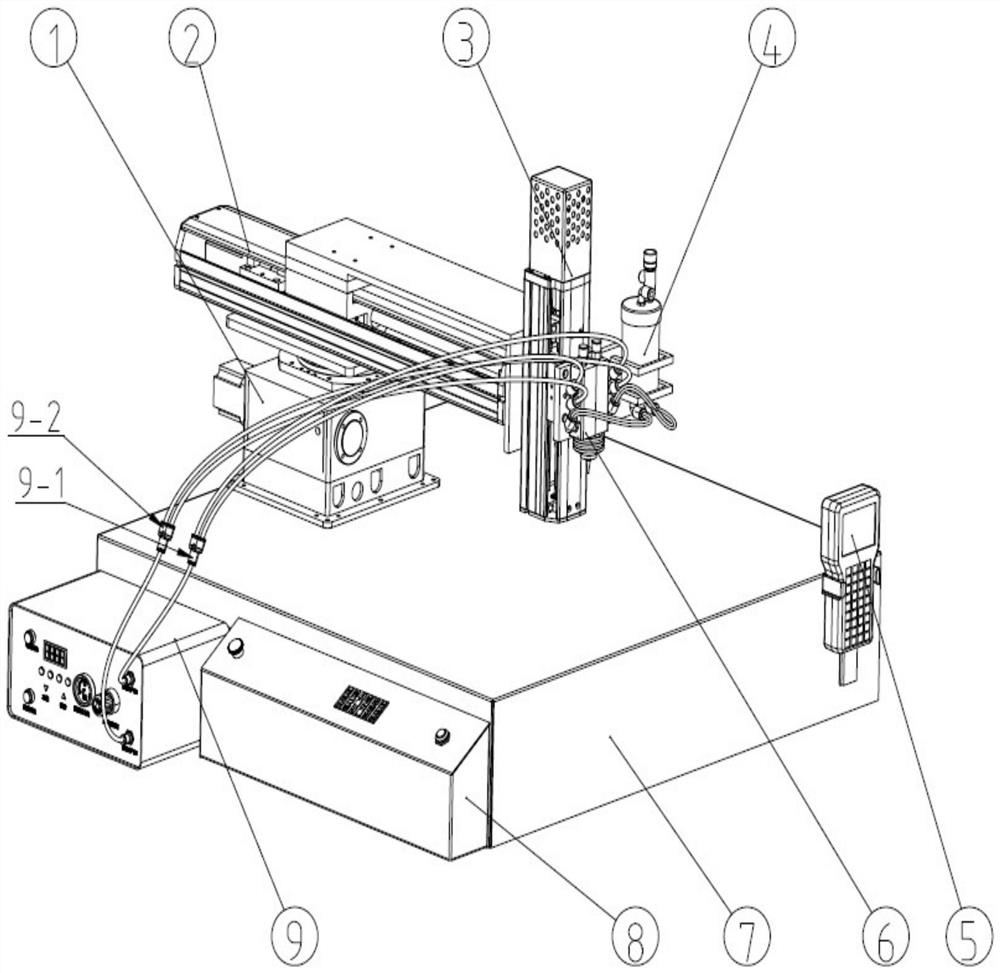

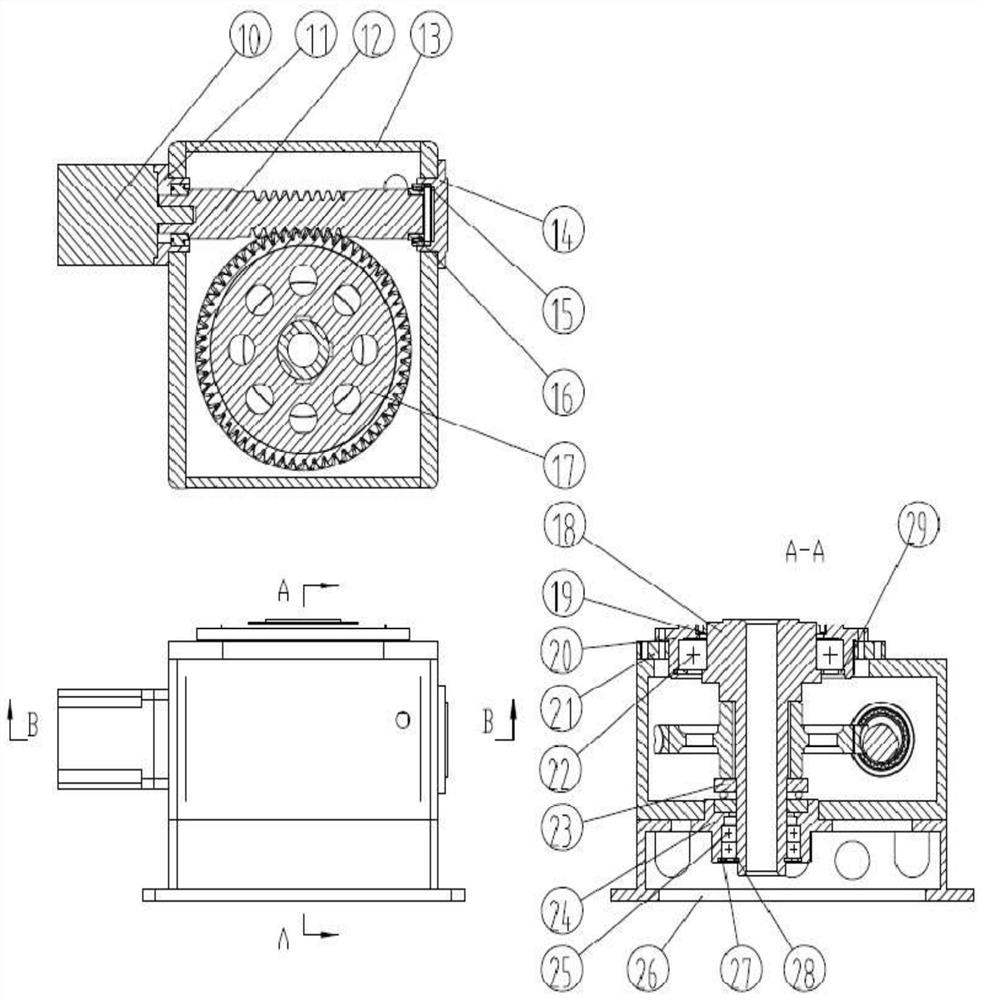

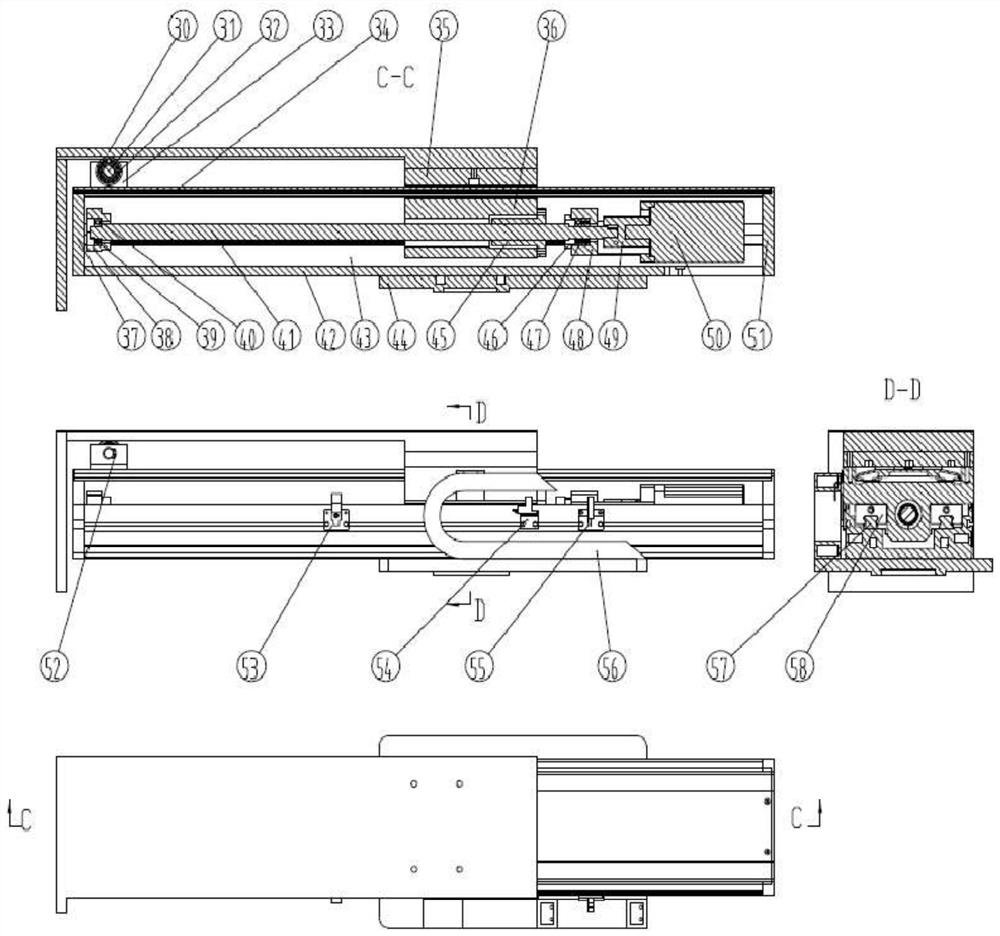

[0030] like figure 1 As shown, the present example provides an automatic dispensing machine for a proton exchange membrane fuel cell bond bonding comprising: a horizontal rotating module 1, a horizontal telescopic die group 2, a vertical heroic die group 3, a mechanical control module 8, Differential glue controller 9, teaching instrument 5, and dual liquid dot rubber valve 6 and double liquid storage tub 4, further comprising point glue platform 7 and two control boxes 8. The horizontal telescopic module 2 is fixed to the horizontal rotary module, and the vertical heave mesh group 3 is fixed at one end of the horizontal telescopic die group 2. The double liquid point adhesive valve 6 and the double liquid storage tub 4 are fixed to the vertical hemp counter set. Positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com