Vacuum vulcanizing machine for making shoes

A vulcanizing machine and vacuum technology, applied in applications, household appliances, household components, etc., can solve the problems of shoe rack turnover, large machine volume, complex structure, etc., and achieve the effect of simple structure and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

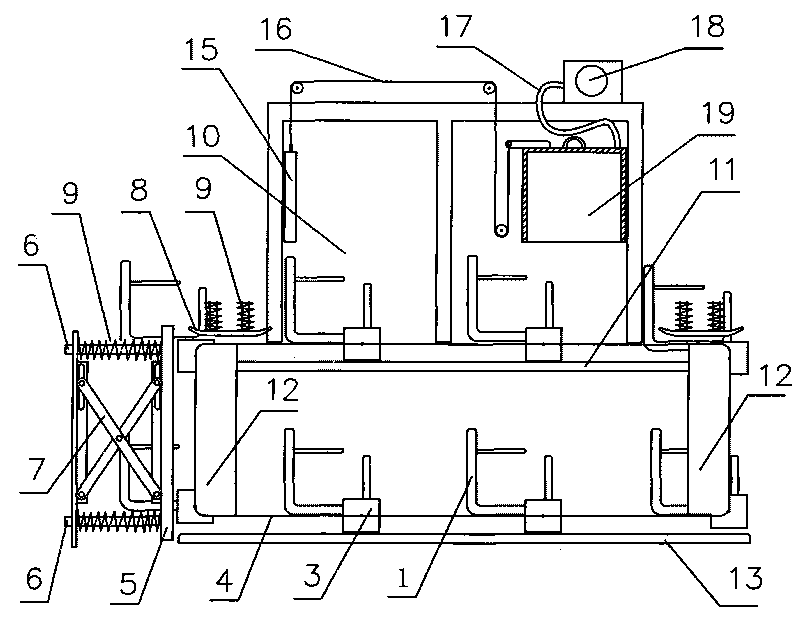

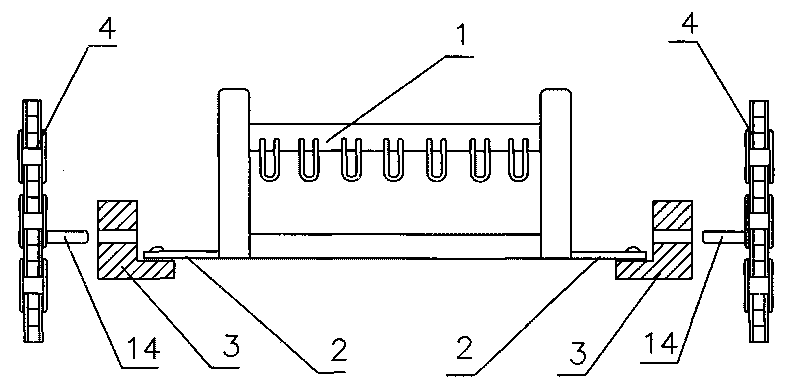

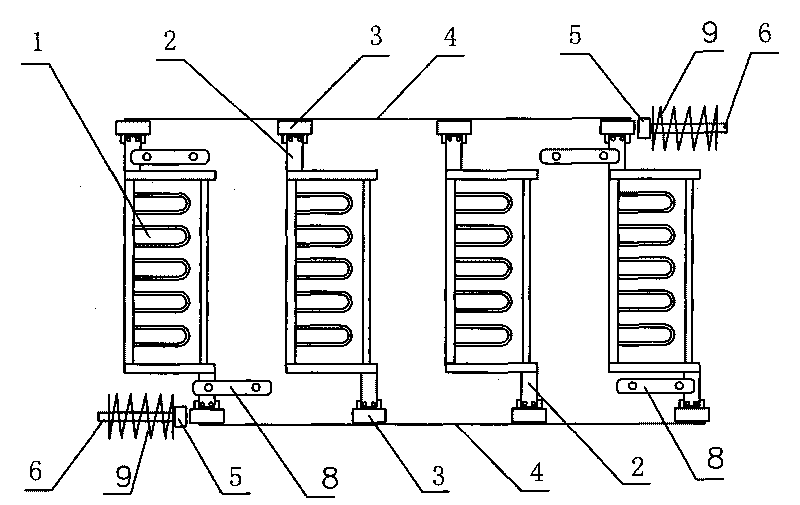

[0030] Such as figure 1 , figure 2 , image 3 As shown, a vacuum vulcanizing machine for shoemaking includes a shoe rack 1, a processing box 10, a vacuum pump 18, a vacuum cover 19, a conveyor chain 4, an upper guide rail 11, a lower guide rail 13, a slider 3, a slide bar 5, and a slide plate 12 and baffle 8. The main function of the processing box 10 is to carry out the heat-and-moisture sizing treatment to the shoe upper, and the main function of the vacuum cover 19 and the vacuum pump 18 is to carry out the evacuation and sizing treatment to the shoes. Process case 10 front end is equipped with process case door 15, and process case 10 rear end is equipped with vacuum cover 19, and vacuum cover 19 is the sealed square container of a bottom opening, and vacuum cover 19 can be lifted upwards under the effect of driving device, also can Cover the shoe rack 1 downwards, and the shoe rack 1 is completely sealed between the vacuum cover 19 and the body. The side wall of vacu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap