Novel shoe shaping machine

A technology of setting machine and new type of shoes, applied in the direction of shoe-making machinery, footwear, clothing, etc., can solve the problems of large size of the whole machine, complex structure, unstable operation of shoe rack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

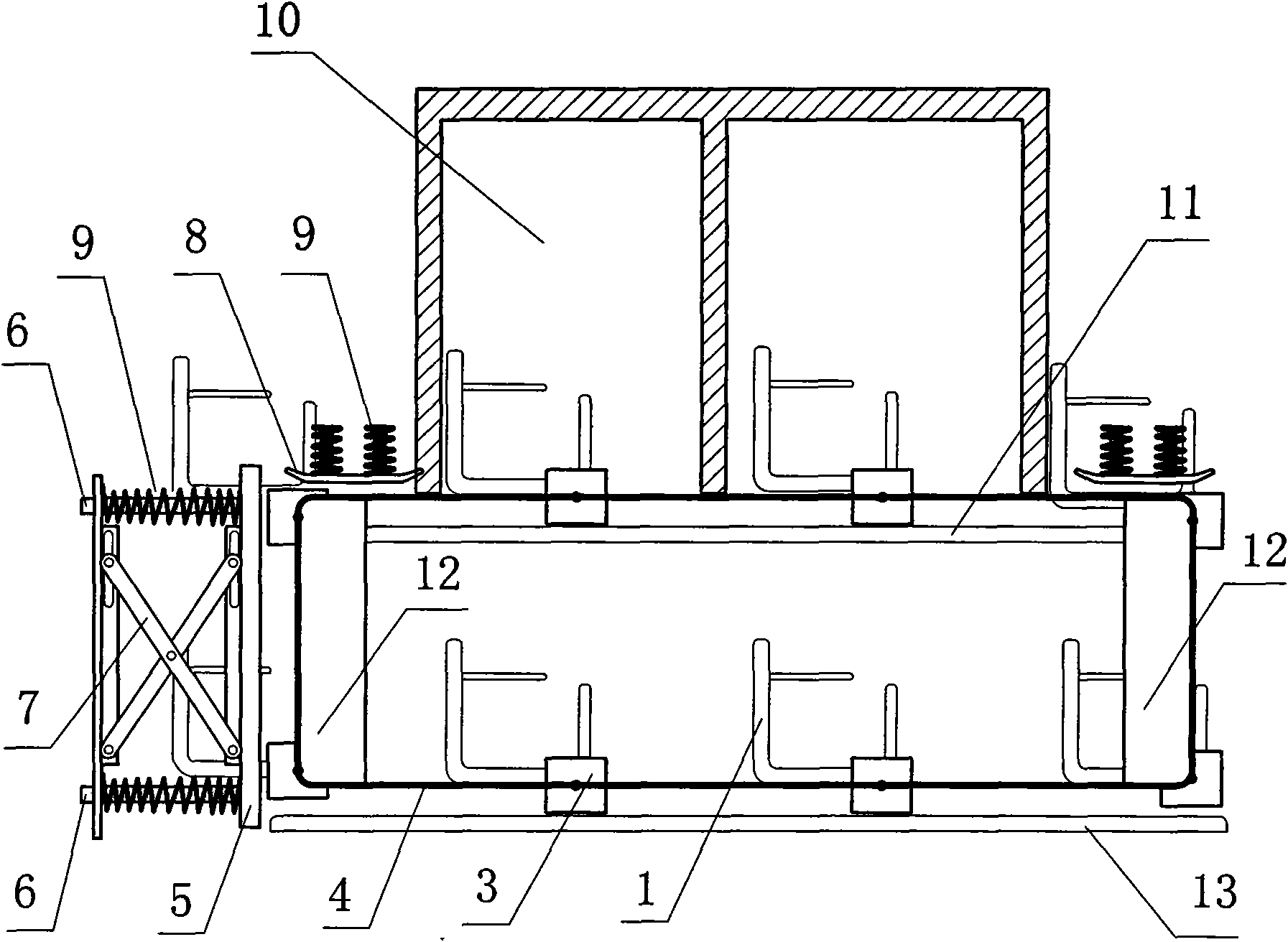

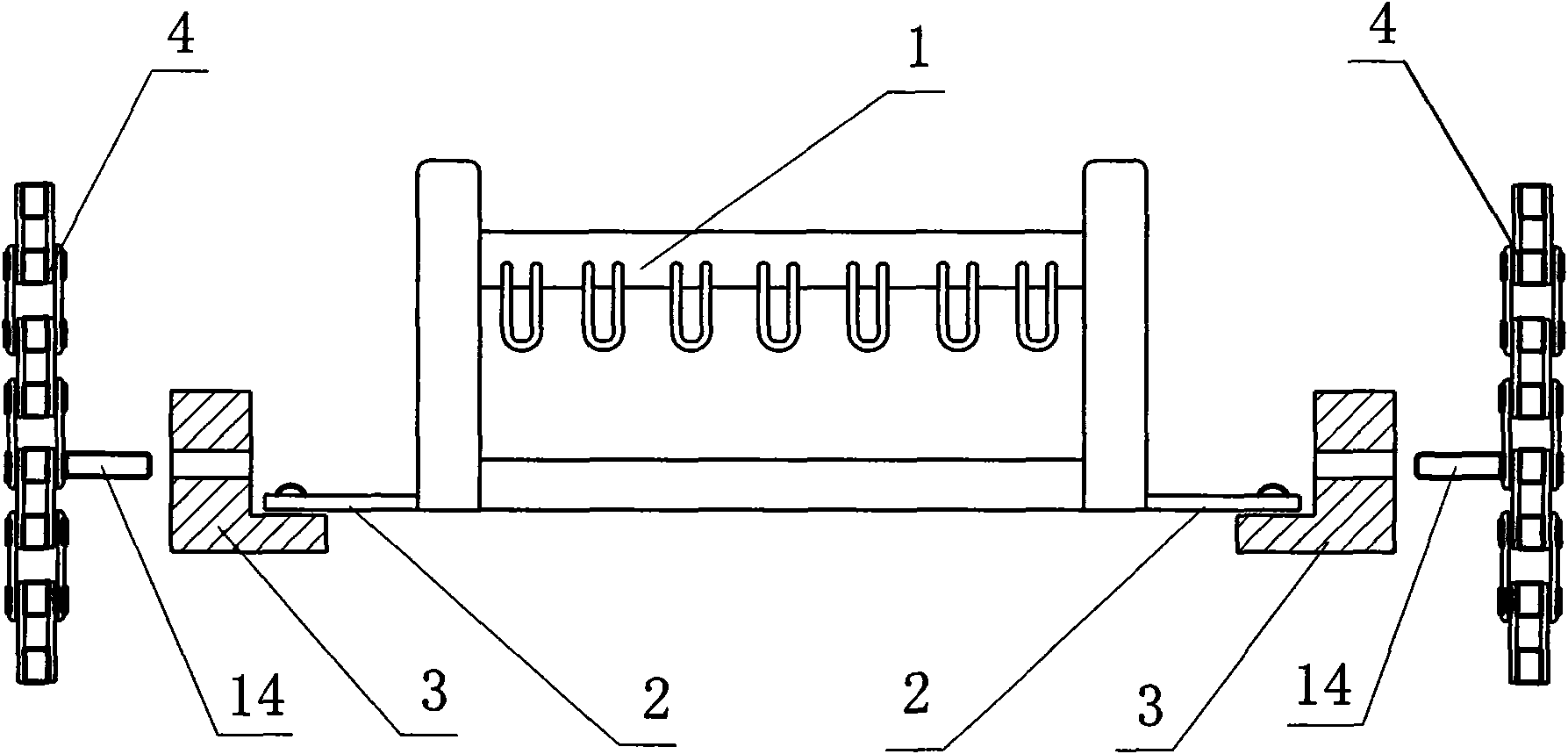

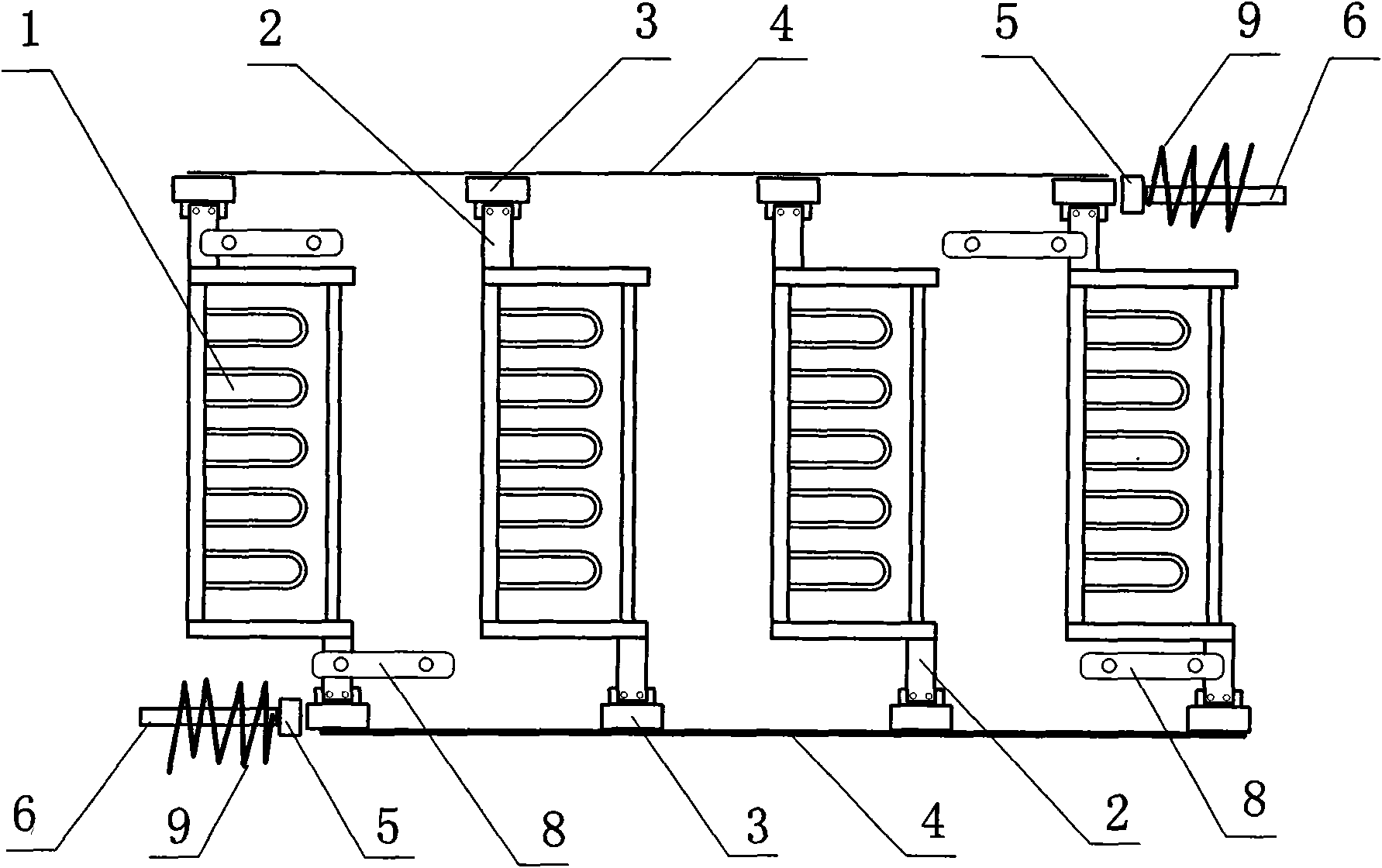

[0025] Such as figure 1 , figure 2 , image 3 Shown, a kind of novel shoe setting machine comprises shoe rack 1, sizing processing box 10, chain 4, upper guide rail 11, lower guide rail 13, slide block 3, slide bar 5, slide plate 12 and baffle plate 8. A supporting plate 2 is respectively installed at both ends of the bottom of the shoe rack 1, and the two supporting plates 2 are installed in a staggered manner. On the same axis, when the supporting plate 2 is movably installed on the chain 4, the shoe rack 1 will not overturn. The shoe rack 1 is driven by the synchronous rotation of the chains 4 on both sides. The chain 4 is closed in a ring and forms a square under the support of the front and rear slide plates 12, the upper guide rail 11 and the lower guide rail 13. The two chains 4 have the same length and are installed in parallel, but they are staggered front and rear. A certain interval, this interval is just the interval between the supporting plates 2 at both ends...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap