Open-type fire resisting window

A fire-proof window, open-type technology, applied in the field of windows, can solve problems such as poor air quality and inability to ventilate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

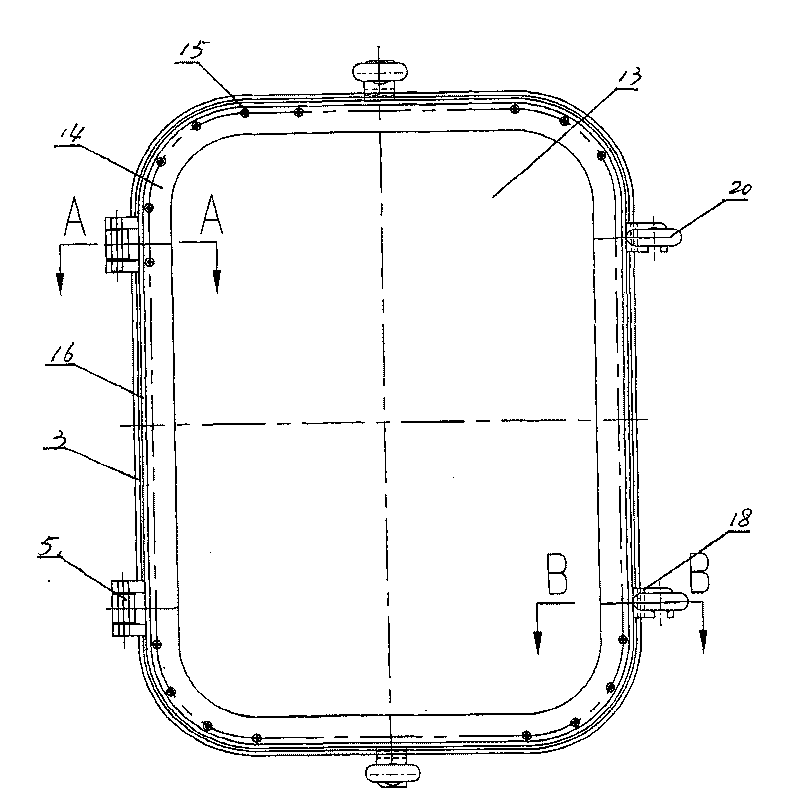

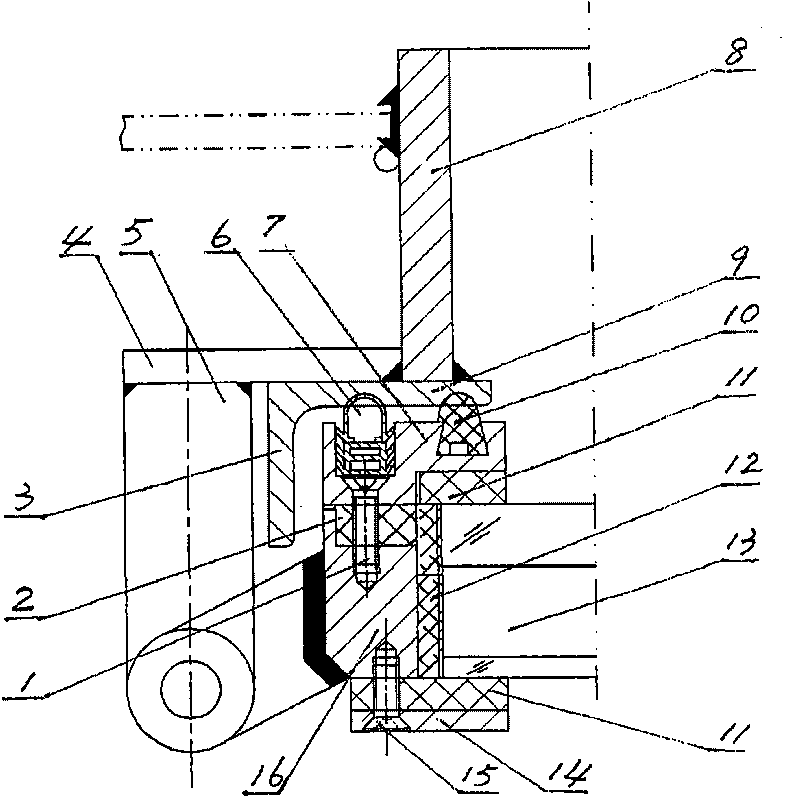

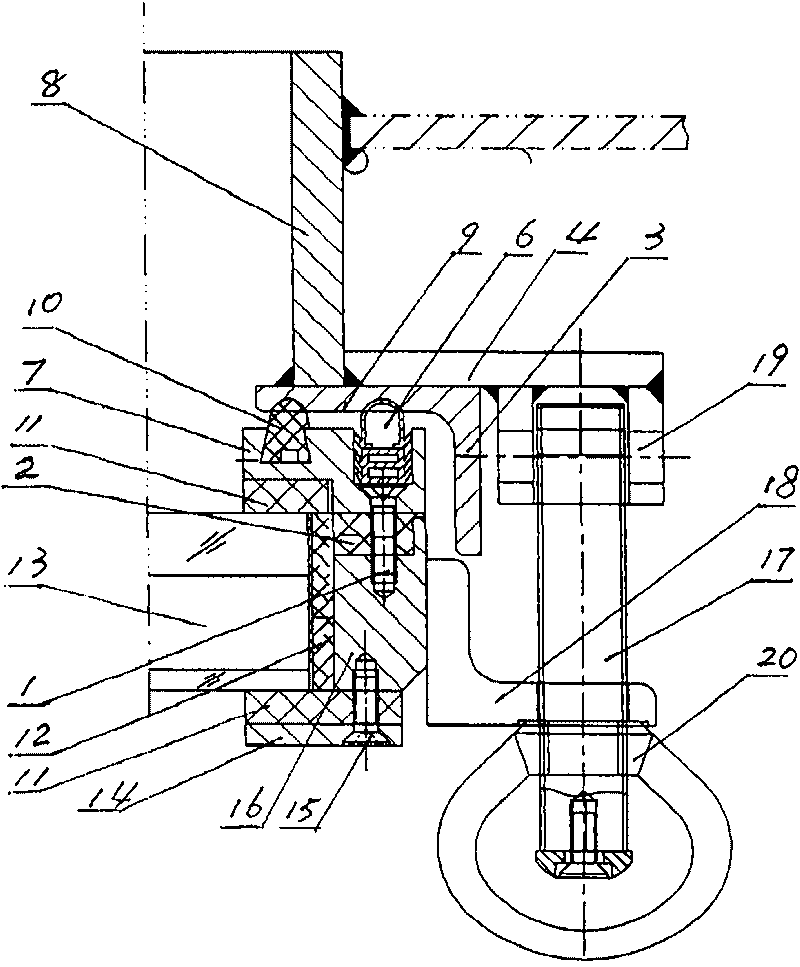

[0012] Such as figure 1 , figure 2 and image 3 As shown, the openable fireproof window of the present invention includes a window frame and a window leaf. The window frame wherein contains main window frame 8 and secondary window frame 9, and described main window frame 8 is welded with thick steel plate. The secondary window frame 9 is an annular flat plate, and its inner edge is welded together with the outer edge of the main window frame 8 in an airtight manner. The outer edge of the secondary window frame 9 is processed with an outer convex edge 3 perpendicular to its plate surface. Described window leaf contains inner frame 7 and outer frame 16, and the width of inner frame 7 is greater than outer frame 16, and the outer limit of inner frame 7 and outer frame 16 is congruent, and fireproof lath 2 is arranged between the two, and inner frame 7, The outer frame 16 and the fireproof slats 2 are connected together by bolts 1 . The outside of outer frame 16 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com