Automatic assembly method for press key support frames

A technology of automatic assembly and support frame, applied in the direction of electrical components, electric switches, circuits, etc., can solve problems such as consuming a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

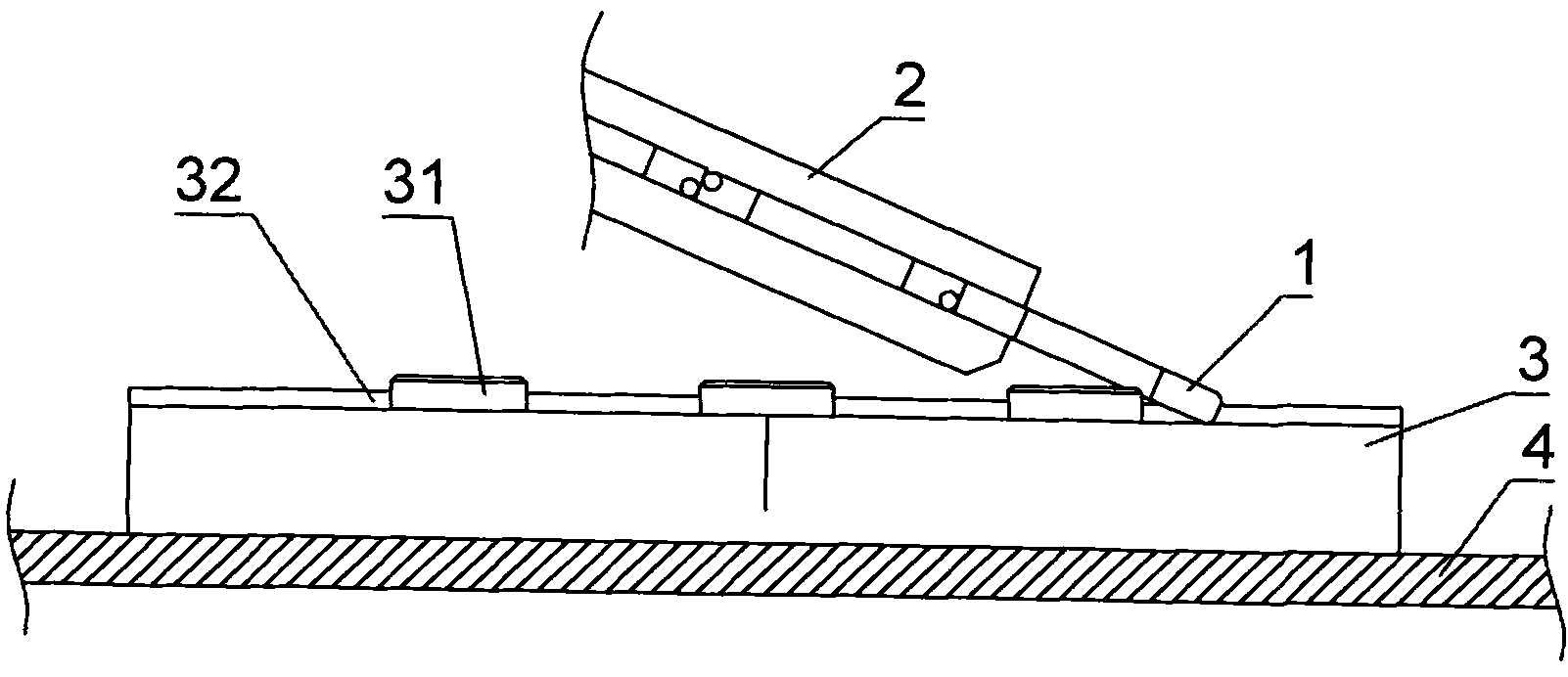

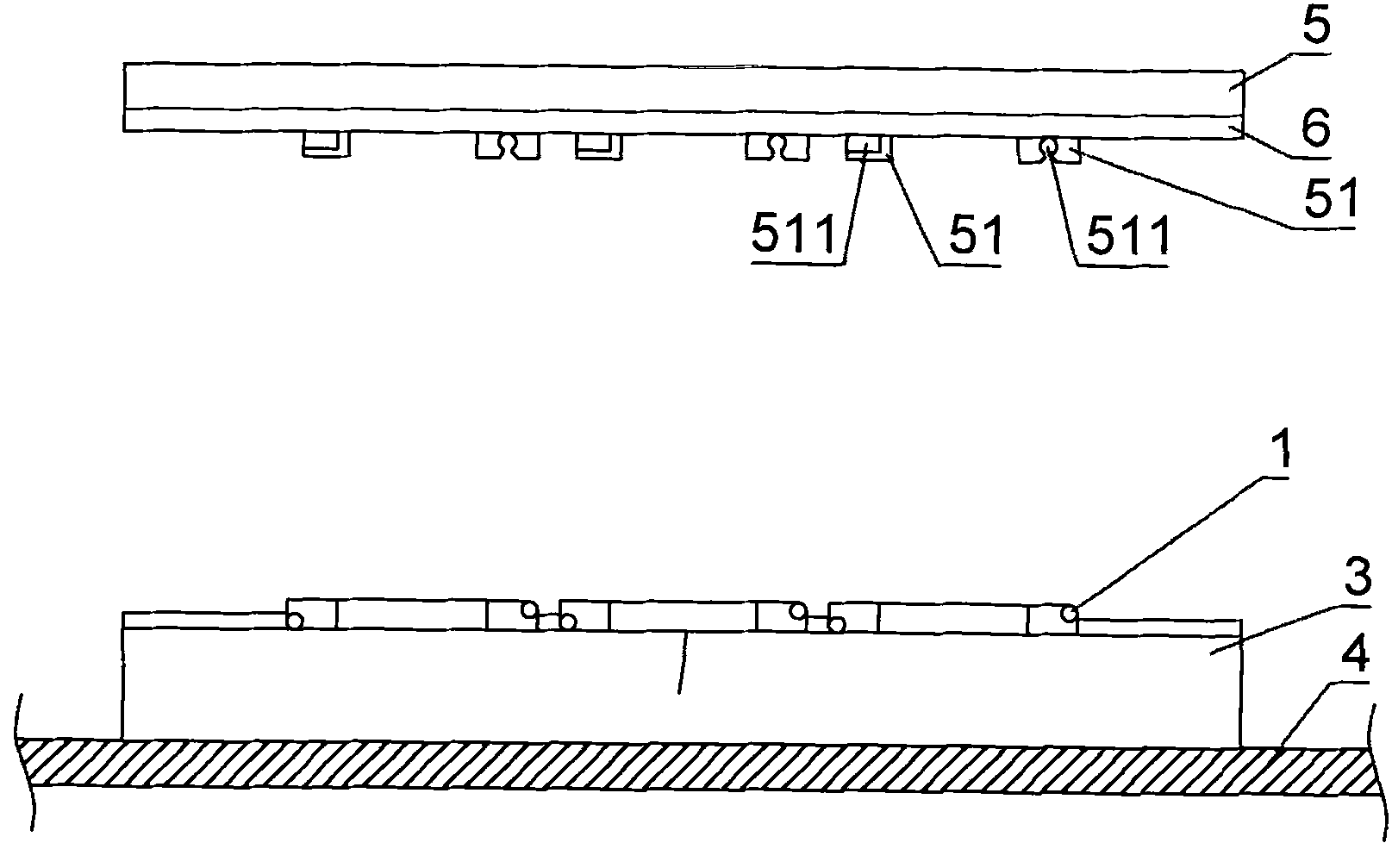

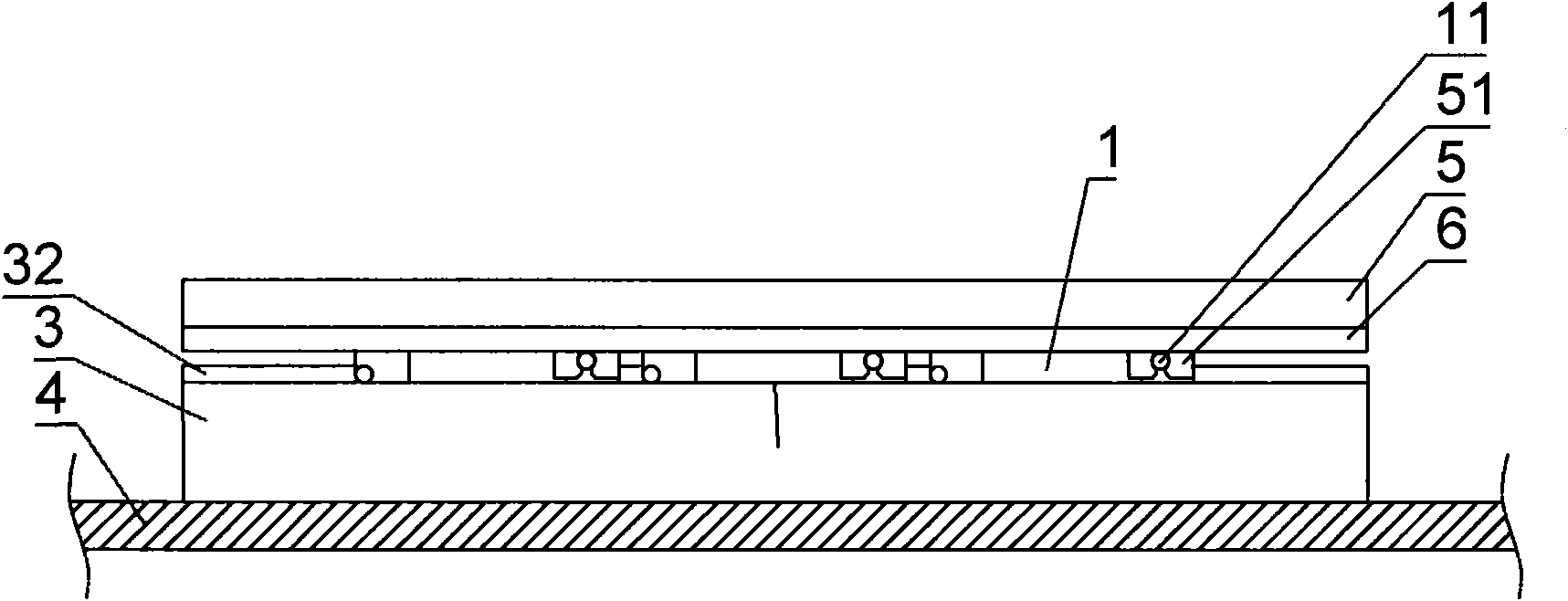

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 According to the first embodiment of the present invention, an automatic assembly method for a key support frame includes: a key support frame 1 , a track 2 , a clamp 3 , a conveyor belt 4 , a bottom plate 5 , and a flexible circuit board 6 .

[0026] A protruding shaft 11 and a round hole 12 are provided on both sides of the front end of the key support frame 1. The key support frame 1 is arranged according to the required direction and passes through a track 2, and the front end of the key support frame 1 slides down onto the fixture 3. The fixture 3 is placed on a conveyer belt 4, and its clamp 3 is provided with a protruding part 31 and a positioning part 32, and its protruding part 31 can take the sliding button support frame 1 away from the track 2, and position it on the positioning part 32. The fixture 3 is moved to the lower side of a base plate 5, the flexible circuit board 6 and a connecting seat...

no. 2 example

[0029] In this embodiment, the same components as those in the first embodiment are marked with the same symbols.

[0030] see Figure 6 , The automatic assembly method of a button support frame in this embodiment includes a button support frame 1, a track 2, a clamp 3, a conveyor belt 4, a bottom plate 5, a flexible circuit board 6, and an elastic body 7.

[0031] An elastic body 7 is arranged below the protruding part 31 of the clamp 3. When the base plate 5 moves downward, the base plate 5 will press the protruding part 31 to move down to allow the base plate 5 to move to an appropriate position. When the base plate 5 is taken out, its protruding The extension part 31 will return to its original position.

[0032] The configurations and functions of other components of this embodiment are the same as those of the first embodiment, so details will not be repeated here.

no. 3 example

[0034] In this embodiment, the same components as those in the first embodiment are marked with the same symbols.

[0035] see Figure 7 , The automatic assembly method of a button support frame in this embodiment includes a button support frame 1, a track 2, a clamp 3, a conveyor belt 4, a bottom plate 5, a flexible circuit board 6, and a bump 8.

[0036] A bump 8 is arranged above the track 4, and when the protruding part 31 takes the sliding button support frame 1 away from the track 2, the bump 8 passes above the button support frame 1 to prevent the button support frame 1 from jumping off.

[0037] The configurations and functions of other components of this embodiment are the same as those of the first embodiment, so details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com