Rotating electric components

A technology of electrical components and rotating components, applied in the direction of electrical components, circuits, electric switches, etc., can solve the problems of weakened automatic running force, inability to get a "click" feeling, increased resistance, etc., and achieve improved automatic running force and good click The effect of feeling and resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

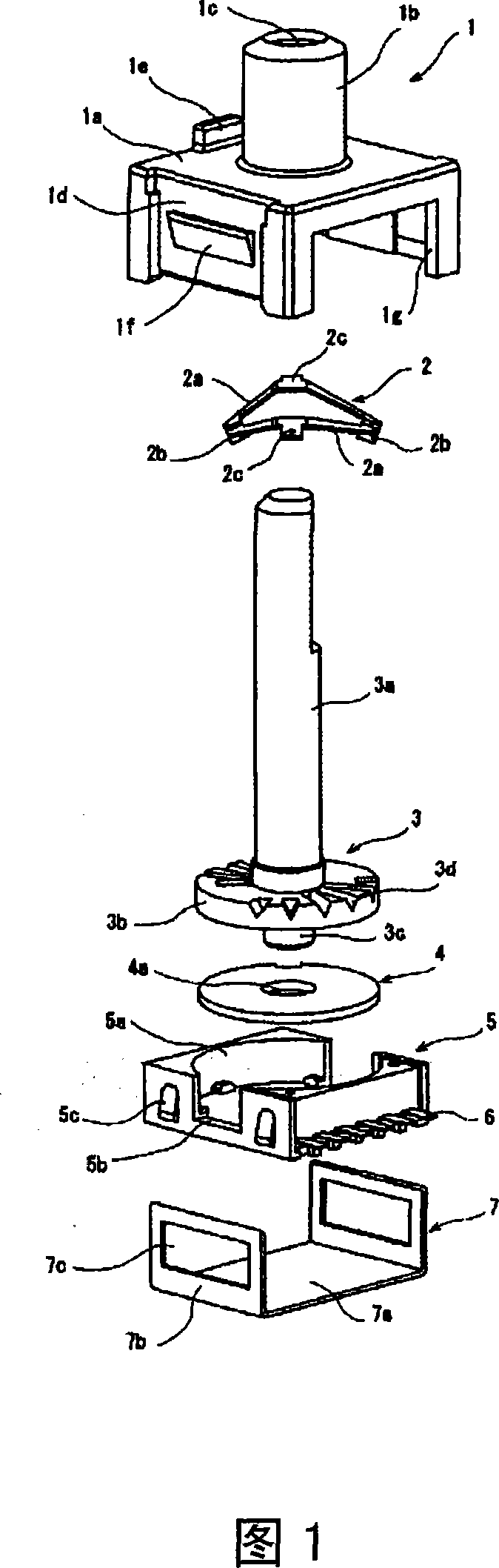

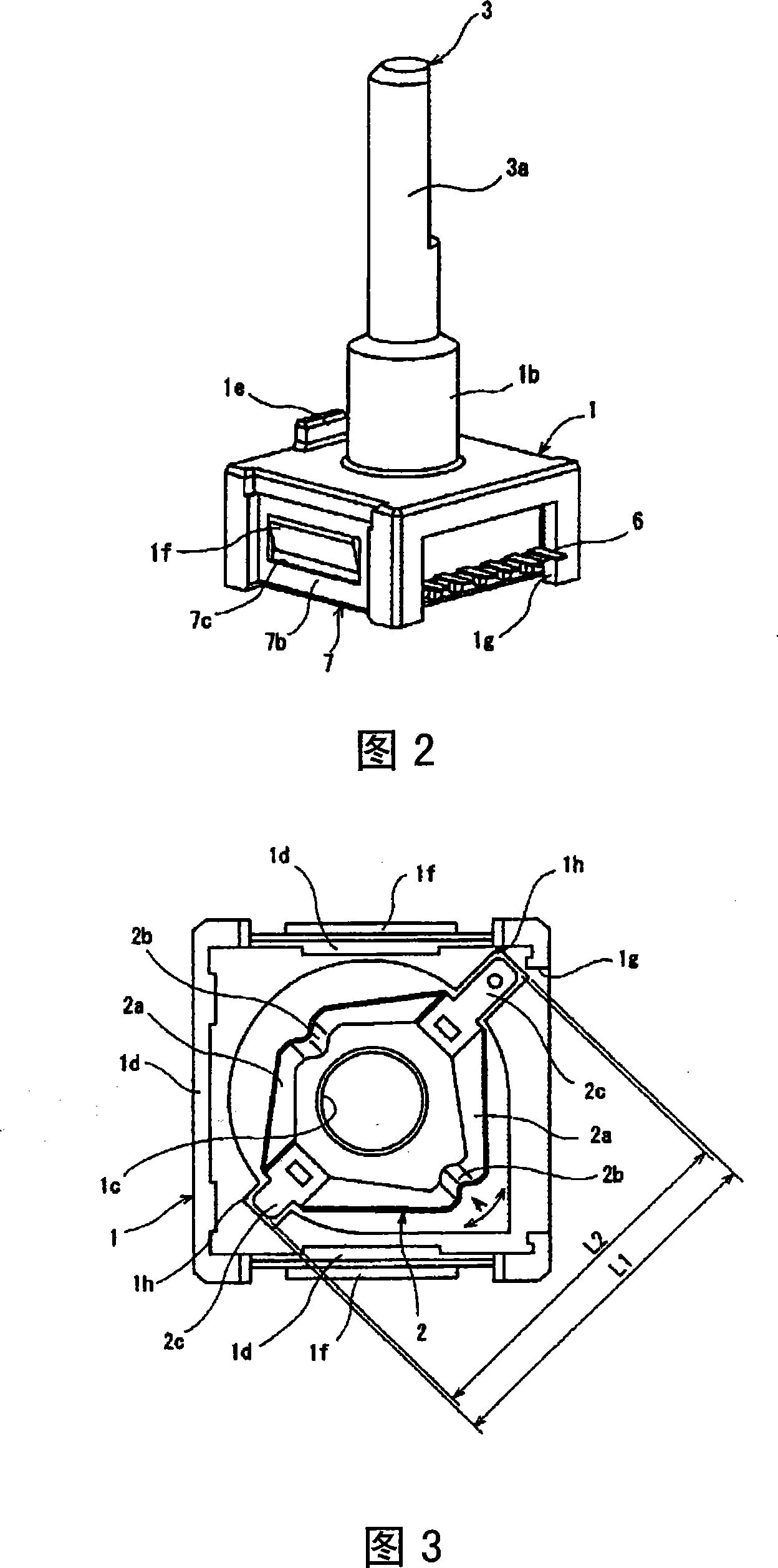

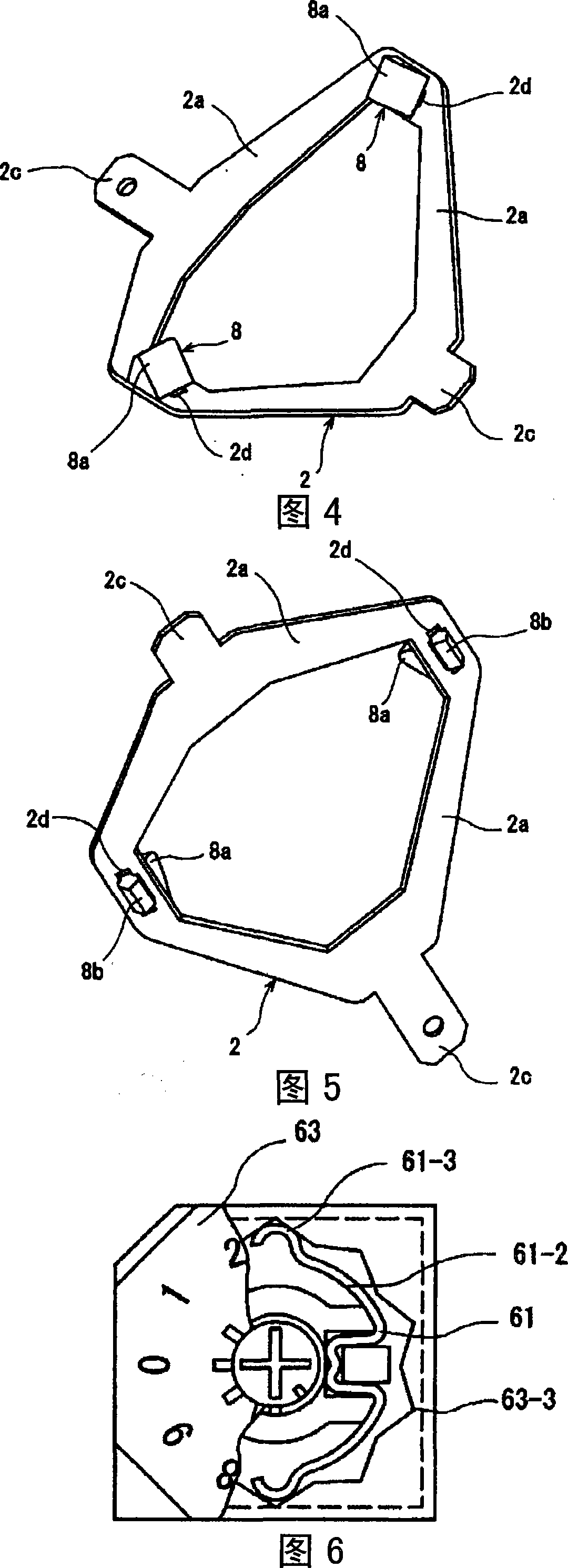

[0034] Hereinafter, FIGS. 1 to 5 show embodiments of the present invention. Fig. 1 is an exploded perspective view showing the rotary electric component of the present invention, Fig. 2 is an assembled perspective view showing the rotary electric component of the present invention, and Fig. 3 is a loose fitting of the box body and the elastic member showing the rotary electric component of the present invention The bottom view of the state, Fig. 4 is a perspective view showing the loose fitting state of the arm portion of the elastic member and the first cam portion of the present invention, and Fig. 5 is a view of the loose fitting state of the arm portion and the first cam portion of the same elastic member from the lower side. A three-dimensional view of the embedded state.

[0035] In FIGS. 1 to 3, the box body 1 is a box-shaped opening made of insulating materials such as synthetic resins, and has: a flat upper plate portion 1a; The bearing portion 1b of the hole 1c; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com