Low-sugar fermented drink and method of producing the same

A technology of fermented beverages and manufacturing methods, applied in the field of malt fermented beverages and its manufacturing, capable of solving the problems of reducing the ratio of sugar to quality, not mentioned, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0102] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples.

reference example 1

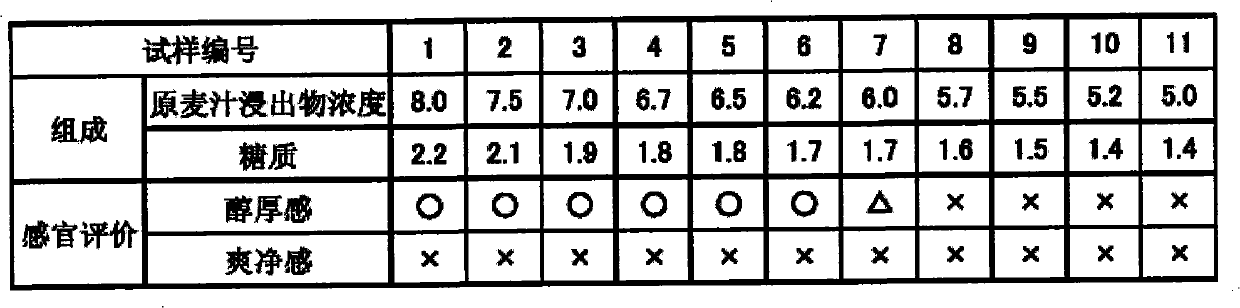

[0103] Reference Example 1 The influence of the original wort extract concentration on the aroma of beer-flavored beverages

[0104] In this reference example, ordinary low-malt liquor was used as a beer-flavored beverage, and the influence of the original wort extract concentration value on the aroma of the beer-flavored beverage was evaluated. Specifically, ordinary sparkling wine (MD GOLDEN DRY (trade name), Japan Suntory Co., Ltd., original wort extract concentration 12.0% by weight, sugar 3.3g, alcohol content 6.0% by volume) was diluted with carbonated water. The concentration of carbonic acid is graded to adjust the concentration of the original wort extract to prepare samples. Sensory evaluation was performed by 20 trained sensory panelists for the richness of the prepared sample and the cleanness of the aftertaste.

[0105] Sensory evaluation is performed by dividing the intensity of the sense of richness and cleanliness into 4 grades of 1, 2, 3, and 4, and the eval...

reference example 2

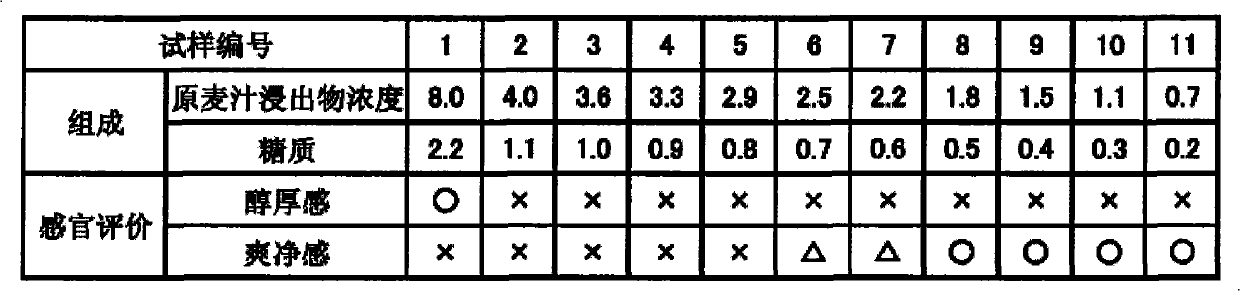

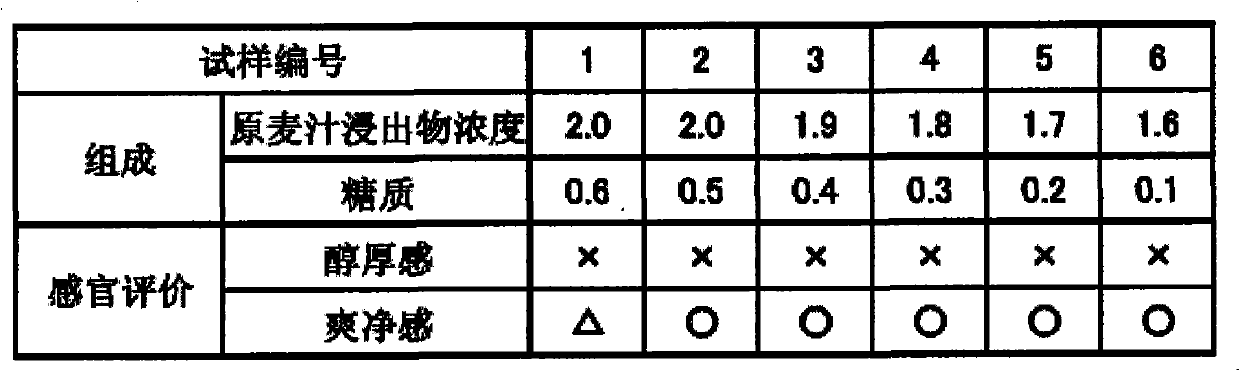

[0110] Reference Example 2 The effect of sugar quality on the aroma of beer-flavored beverages (Part 1)

[0111]In Reference Example 2, the influence of sugar quality on the aroma production of beer-flavored beverages was evaluated. As an example of a beer-flavored beverage, an example in which the sugar content and the flavor of the beer-flavored beverage are evaluated using ordinary low-malt liquor is illustrated. Specifically, common sparkling wine (MD GOLDEN DRY (trade name), Suntory Co., Ltd., original wort extract concentration 12.0% by weight, sugar 3.3g, alcohol content 6.0% by volume) was diluted with carbonated water, The concentration of the original wort extract was adjusted in grades to prepare samples. Sensory evaluation was performed on each sample. The sensory evaluation, the concentration of the original wort extract, and the measurement of sugar quality were performed by the method described in Reference Example 1. The results are shown in Table 2.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com