Kerf sand inclusion blasting cartridge and blasting installation device and production technology thereof

An installation device and slitting technology, applied in the direction of ammunition, ammunition storage, weapon accessories, etc., can solve the problem that the gas gushing cannot be guaranteed to be reduced to the required level, the gas drainage effect has not been improved, and the gas drainage cannot be achieved. Outburst prevention and other problems, to achieve the effect of improving underground safety operations, reducing gas disasters, and reducing ventilation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The accompanying drawings disclose an embodiment of the present invention without limitation, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

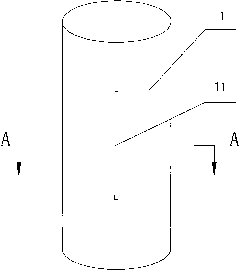

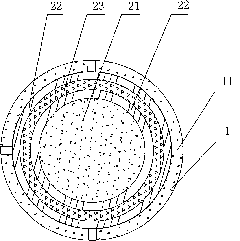

[0022] Such as figure 1 , figure 2 As shown, the slit sand-containing drug pack of the present invention includes a slit tube 1 and a drug pack 21 installed in the slit tube 1, and the tube wall of the slit tube 1 is equally spaced in a circular array. There are four slits 11, the slits 11 have a slit width of 3.0-5.0 mm, and at the same time, a sand-containing cartridge is arranged between the drug pack 21 and the slit pipe 1, and the drug pack 21 is placed in the sand-containing cartridge Inside, the diameter of the slit pipe 1 is 2.0-4.0 mm wider than that of the sand-containing cartridge.

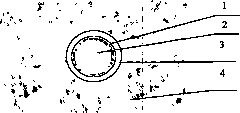

[0023] During blasting, the slit sand-containing charge bag of the present invention is installed in the blast hole 3, such as image 3 As shown, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Seam width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com