Enhanced prism sheet

A technology of prism film and truncated cone, which is applied in the direction of light guide, optics, instruments, etc., can solve the problems of not getting better effect, poor light guiding effect, and decrease of prism film brightness, so as to avoid light interference, expand viewing angle, and good focus light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

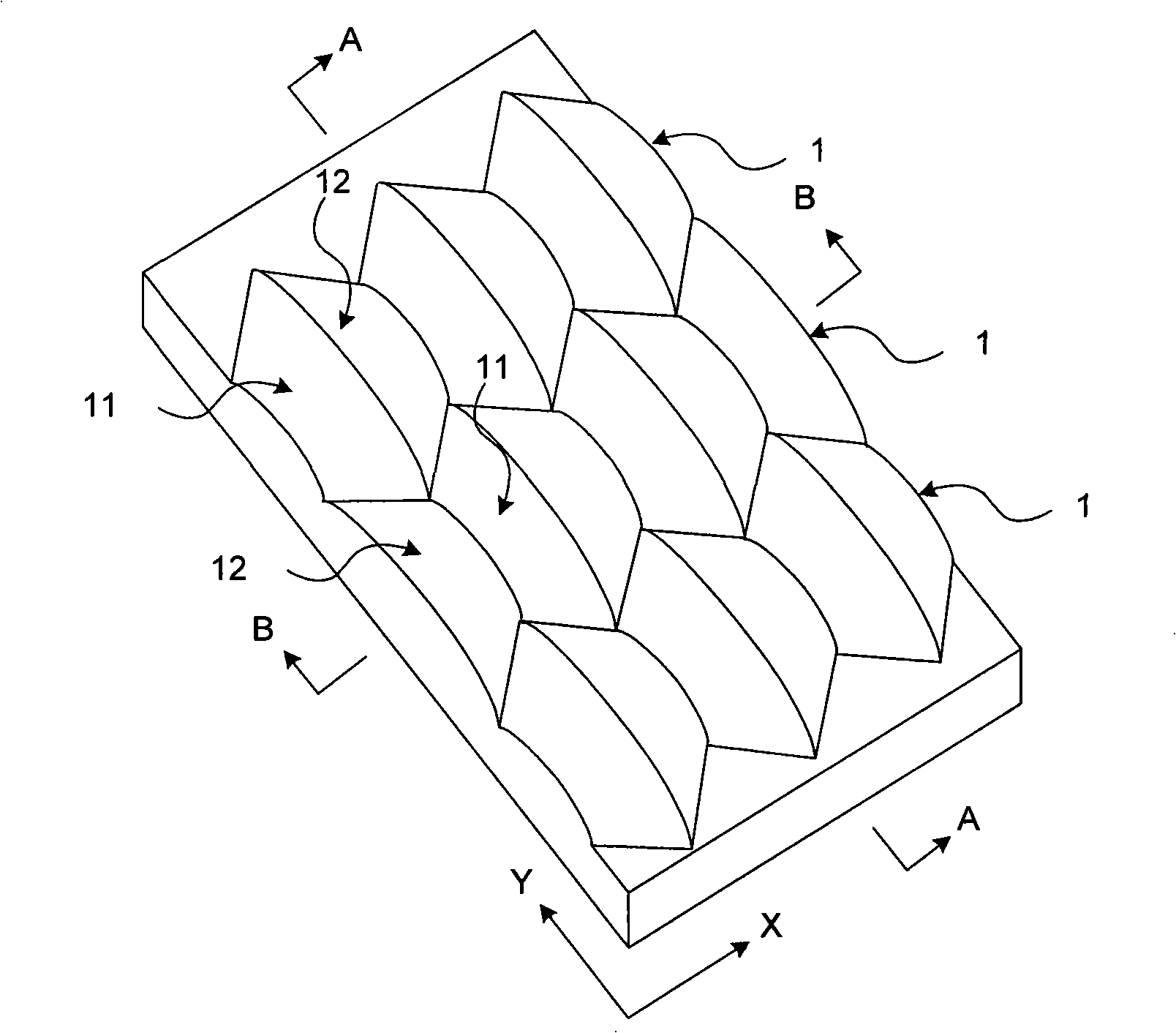

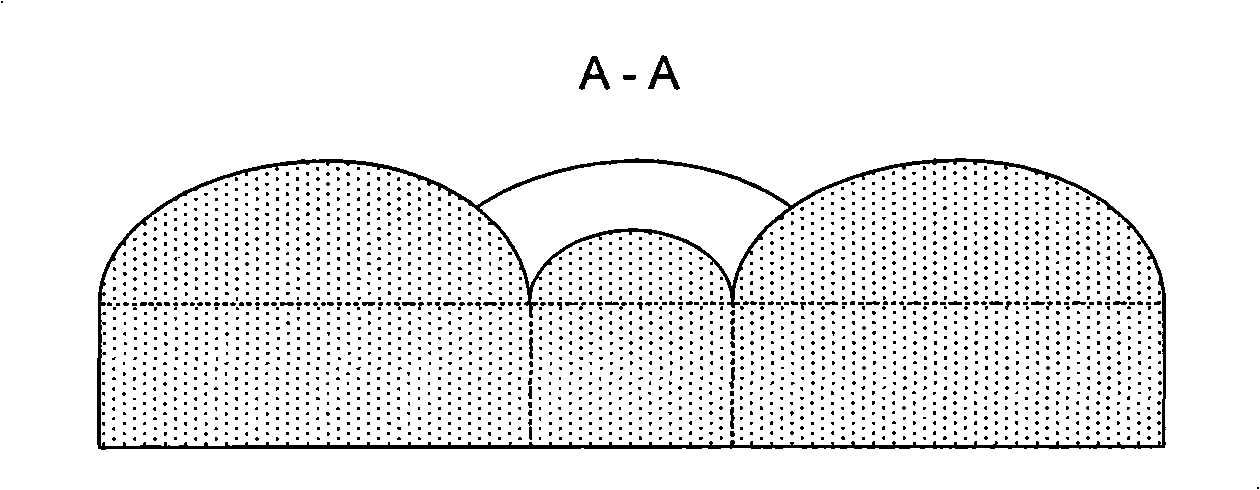

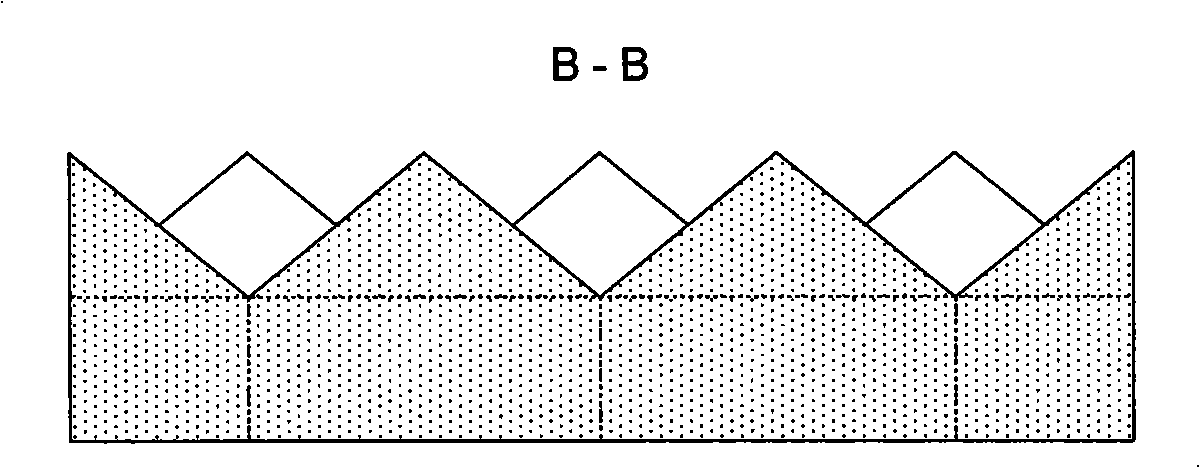

[0026] figure 1 It is a schematic structural diagram of the first embodiment of the enhanced prism film of the present invention. Such as figure 1 As shown, the enhanced prism film of this embodiment includes several cylindrical bodies 1, each cylindrical body 1 is composed of several first frustums 11 and second frustums 12, and the first frustum 11 and the second frustum 12 are connected in sequence And extend along the first direction X, the conical bottom of each first conical frustum 11 is docked with the conical bottom of the adjacent second conical frustum 12, and the conical top of each first conical frustum 11 is connected to the conical bottom of the adjacent second conical frustum 12. The cone tops are butted to form a cylindrical body similar to a straight thread structure. Several cylindrical bodies 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com