Flange assembly of oil feeding device for vehicle and electrical plug

A technology of oil supply device and electric plug, which is applied in the direction of vehicle components, power devices, and the arrangement combined with fuel supply of internal combustion engines, etc., which can solve the limitation of universality of flange components, high cost of molds, difficulty in meeting the requirements of function definition, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

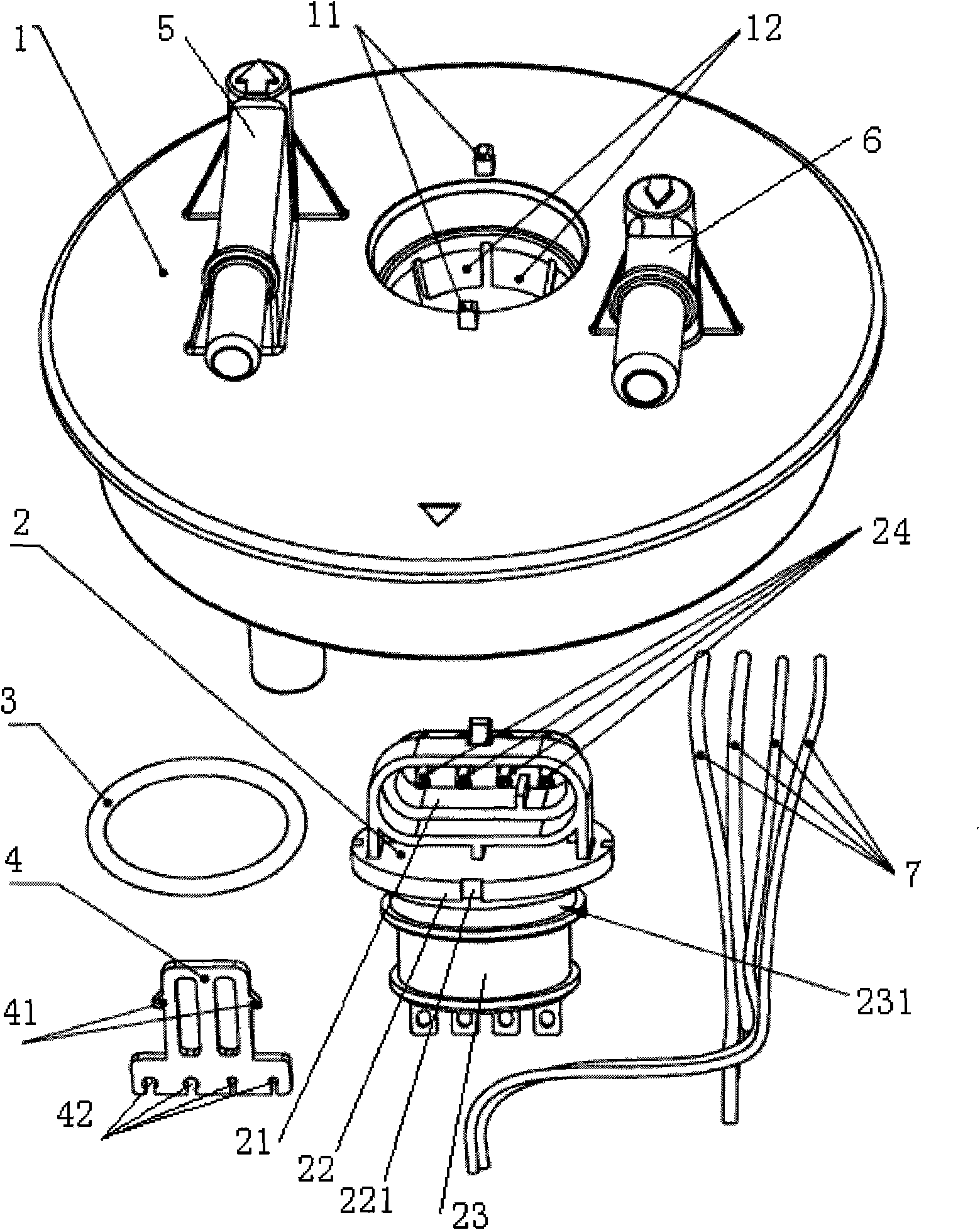

[0030] An embodiment of the flange assembly of the vehicle oil supply device of the present invention is as follows: image 3 , Figure 4 As shown, it includes a flange 1, an oil outlet pipe 6, an oil return pipe 5, an electric plug 2, an O-ring 3, a wire harness clip 4, etc.; the flange 1 is provided with a round hole for installing an electric plug, and the method There are two protrusions 11 arranged symmetrically with the center of the circle on the periphery of the electric plug installation hole on the outside of the blue plate, and elastic grips 12 are arranged on the periphery of the electric plug installation hole on the inner surface of the flange; the electric plug 2 includes a positioning circular plate 22, Power interface 21, wire harness interface 23, a plurality of metal inserts 24, the power interface 21 is located outside the positioning circular plate 22, the wire harness interface 23 is located inside the positioning circular plate 22, the positioning circul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap