Battery combination cover and battery

A technology for combining a cover and a battery is applied to the battery. It can solve the problems of battery capacity reduction, increase internal space, etc., and achieve the effect of increasing battery capacity, reducing height, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

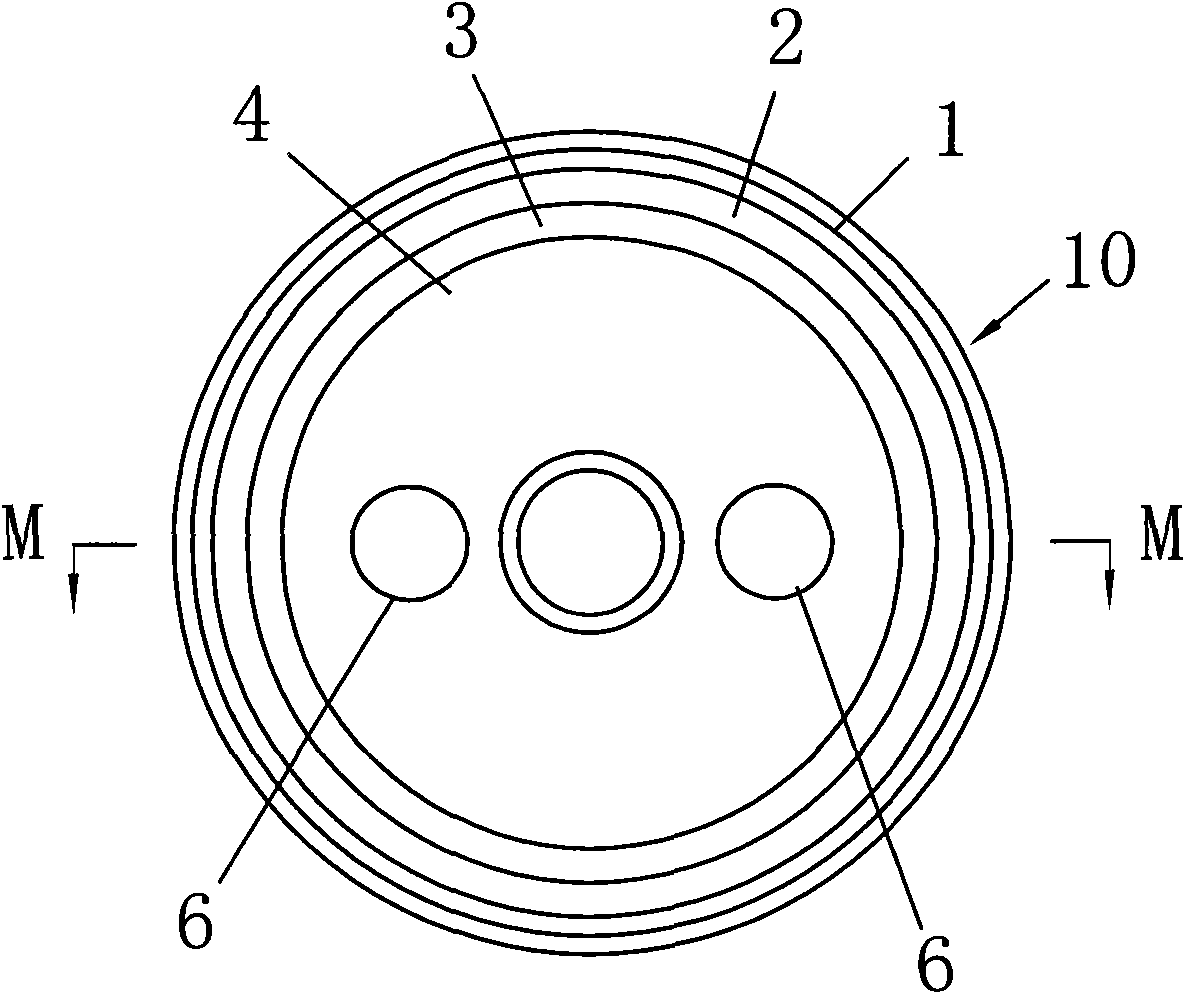

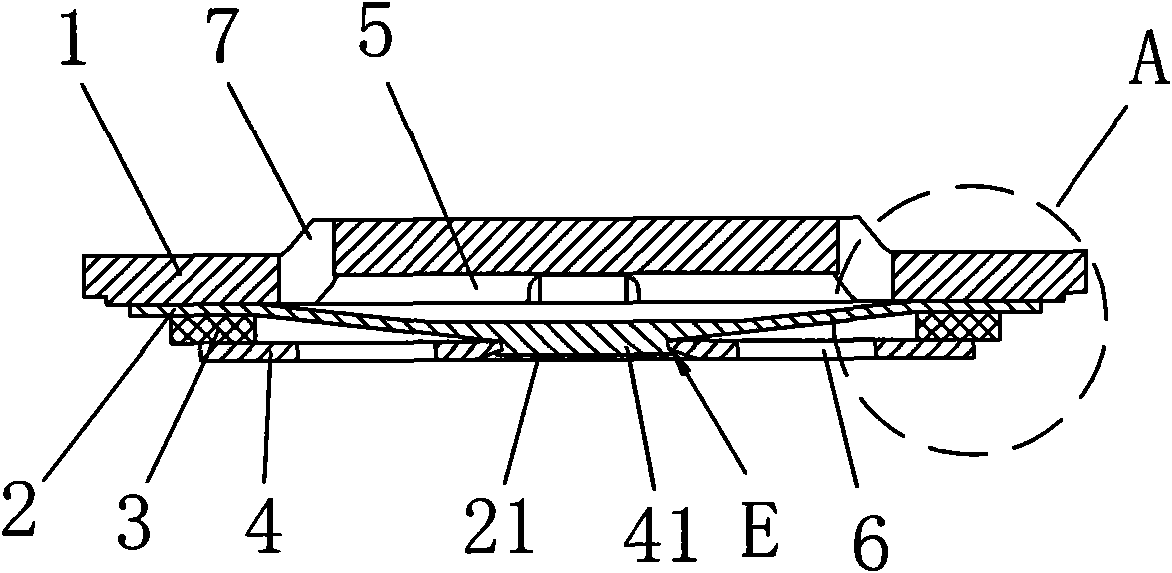

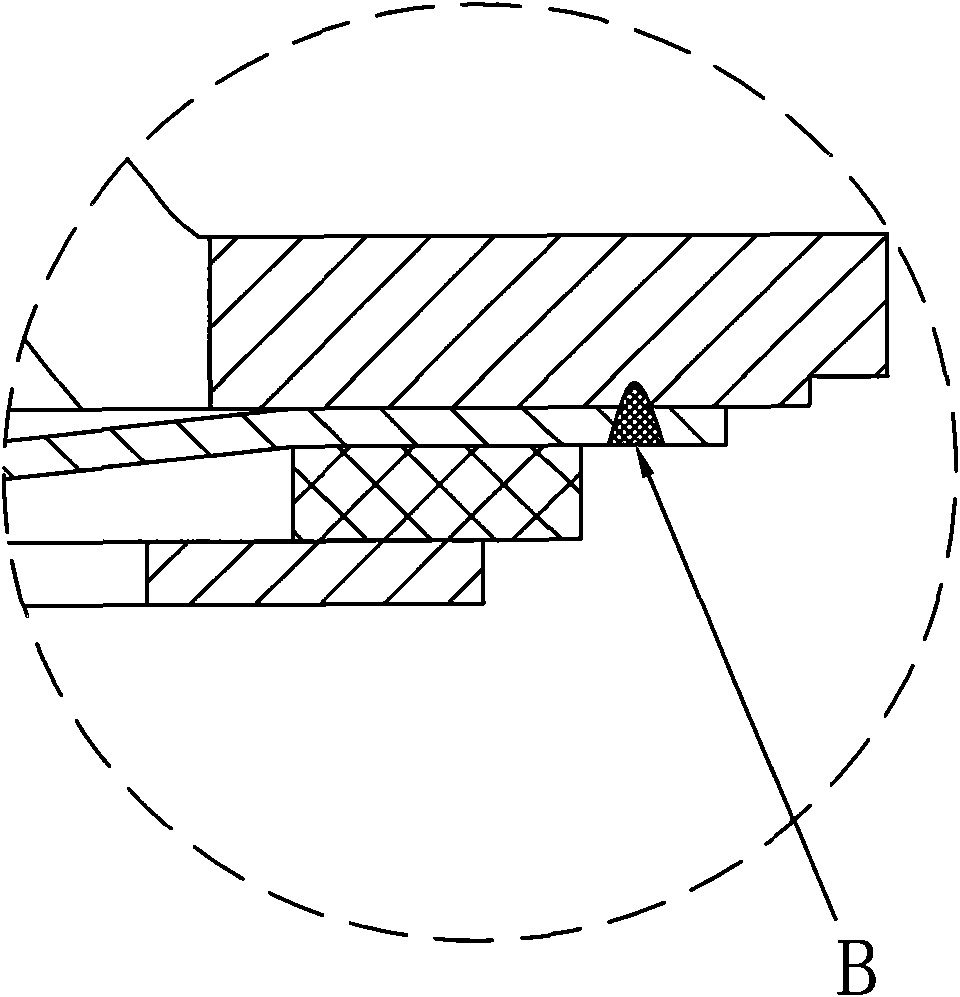

[0033] like Figure 1 to Figure 4 As shown, a battery combination cover 10 includes a top cover 1 , an explosion-proof membrane 2 , a pull plate 4 , and an insulator 3 . A sealed electrical connection is made between the lower surface of the top cover 1 and the explosion-proof membrane 2, and a pressure relief chamber 5 is formed between the top cover 1 and the explosion-proof membrane 2; a pull plate 4 is arranged below the explosion-proof membrane 2, such as figure 2 The middle part of the shown explosion-proof membrane 2 is fixedly electrically connected to the middle part of the pull plate 4; as figure 2 As shown, the insulator 3 is provided in the non-electrical connection area between the peripheral lower surface of the explosion-proof membrane 2 and the peripheral upper surface of the pull plate 4 . Among them, the sealed electrical connection between the top cover 1 and the explosion-proof membrane 2 can be laser welding, high-temperature flame welding, or conductiv...

Embodiment approach 2

[0039] Such as Figure 6 to Figure 9 As shown, a battery combination cover 20 in this embodiment is further improved on the basis of the battery combination cover 10 in the first embodiment. The improvements are as follows: one is that the lower surface of the top cover 1 is provided with a boss 8 for positioning the explosion-proof membrane 2; Welding speed between 2. More importantly, the boss 8 is annular, and the gap between the inner wall of the boss 8 and the periphery of the explosion-proof membrane 2 is used as a laser welding site (such as Figure 8 The place indicated by the middle arrow D), the laser beam goes deep into the gap during welding, of course, in other embodiments, the high-temperature flame can also be used to go deep into the gap, so as to heat the two parts of the top cover 1 and the explosion-proof membrane 2 at the same time to form a deeper The weld pool formed by welding can be greatly improved in sealing and strength. The second is that the per...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap