Fully mechanized coal face bracket withdrawing method and withdrawing bracket traction spring exerciser

A technology of fully mechanized mining face and tension device, which is applied to pillars/supports, mining equipment, earth-moving drilling, etc., can solve the problems of long construction period, large materials, time-consuming and labor-intensive, etc. Time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

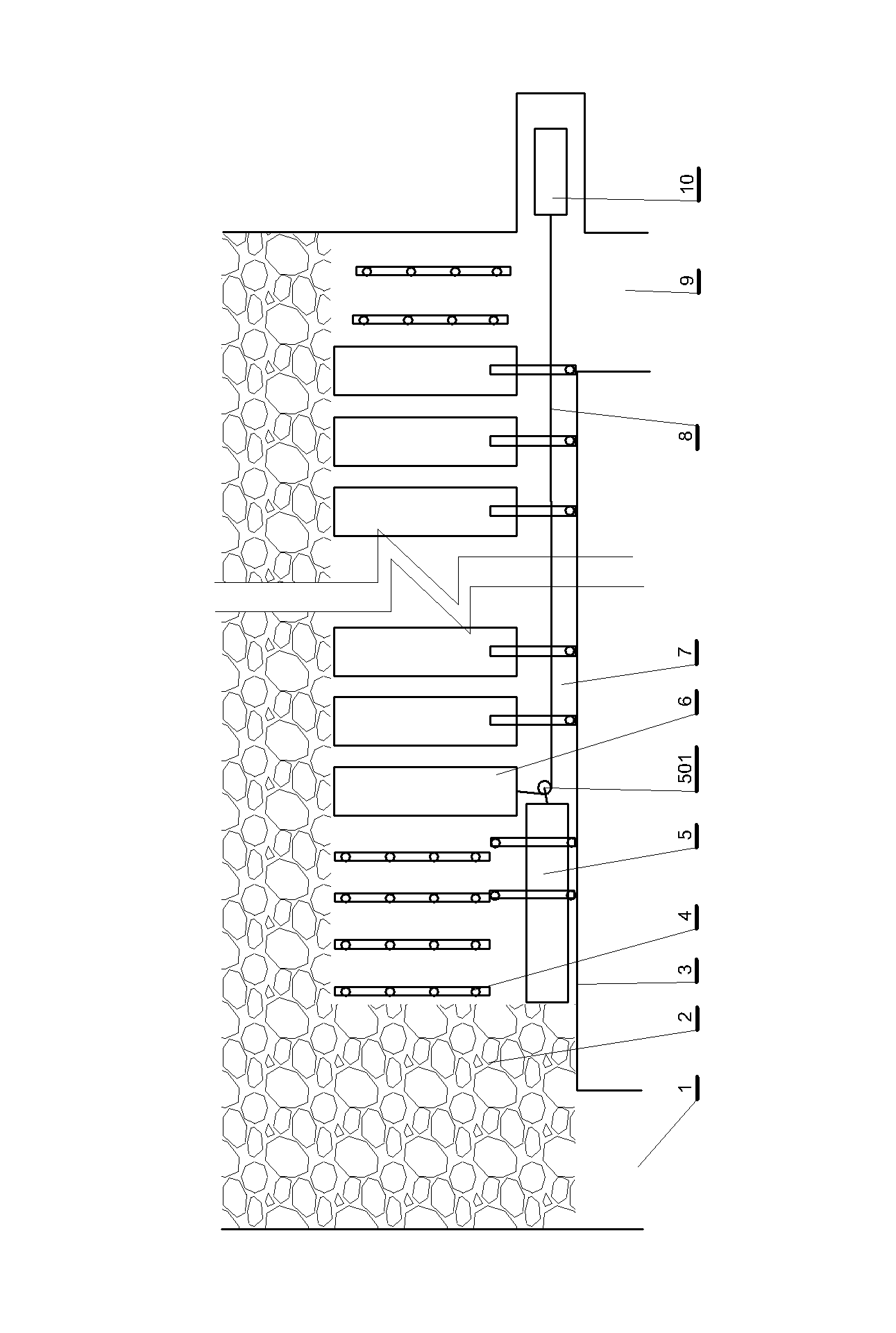

[0028] figure 1 It is a schematic diagram of the retraction of the support in the fully mechanized mining face. In the figure, track channel 1, withdrawal channel 7 and transportation channel 9 form the original fully mechanized mining channel, and the withdrawal channel is the original fully mechanized mining face. Since the coal mining of this working face has been completed, the coal seam is cut into a goaf In area 2, the position where cutting can no longer be continued is the coal side 3 of the stop mining line, and the supports are erected side by side on the side of the evacuation passage before evacuation. figure 1 Middle 6 is the position before stent withdrawal. In order to ensure safety, each support must be connected to the top before evacuation, and it will only be lowered when it is the turn to evacuate. Also will use single hydraulic prop 4 to support around this support before lowering, prevent from collapsing. After lowering, use the two-speed winch 10 to e...

Embodiment 2

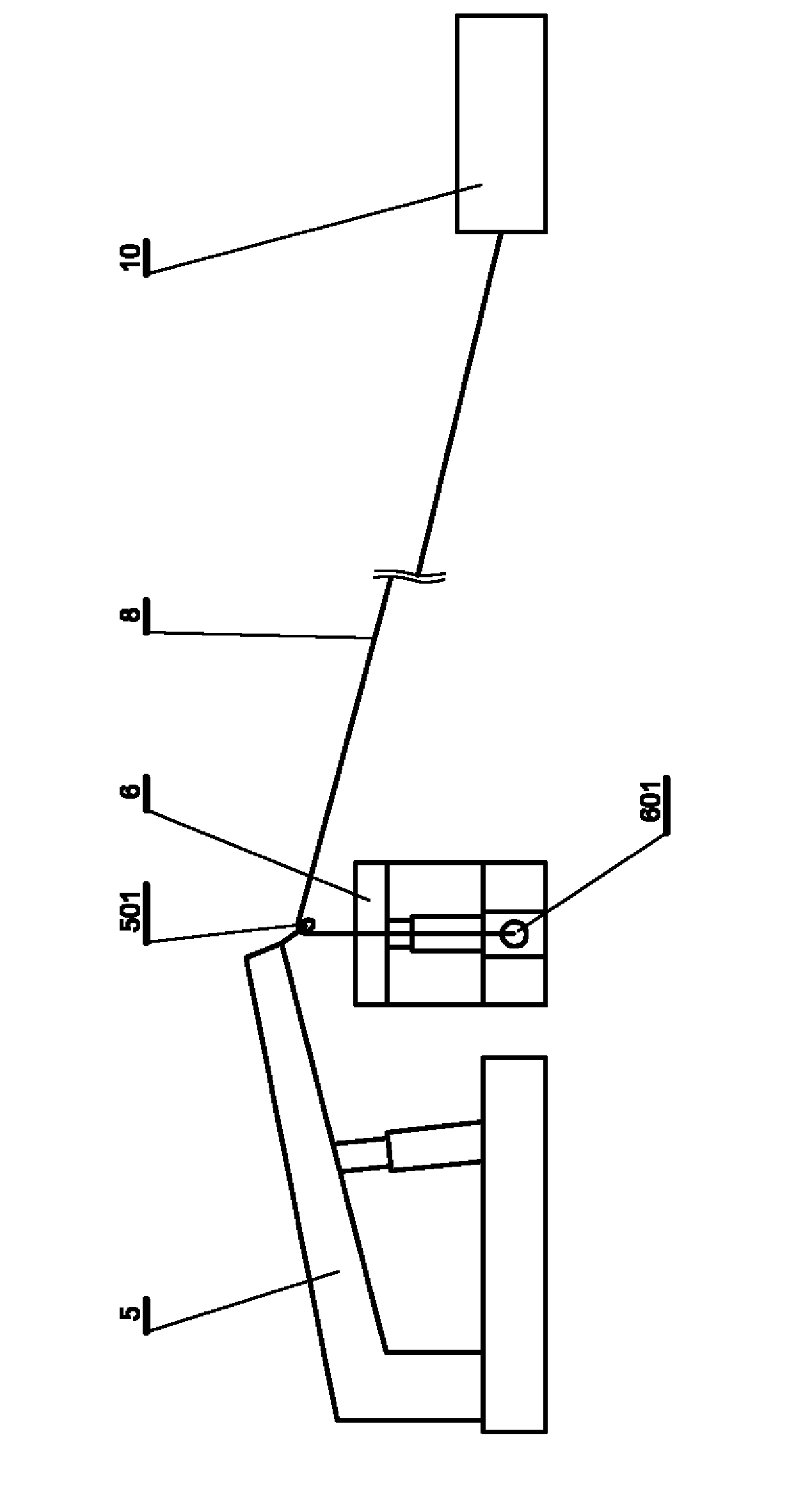

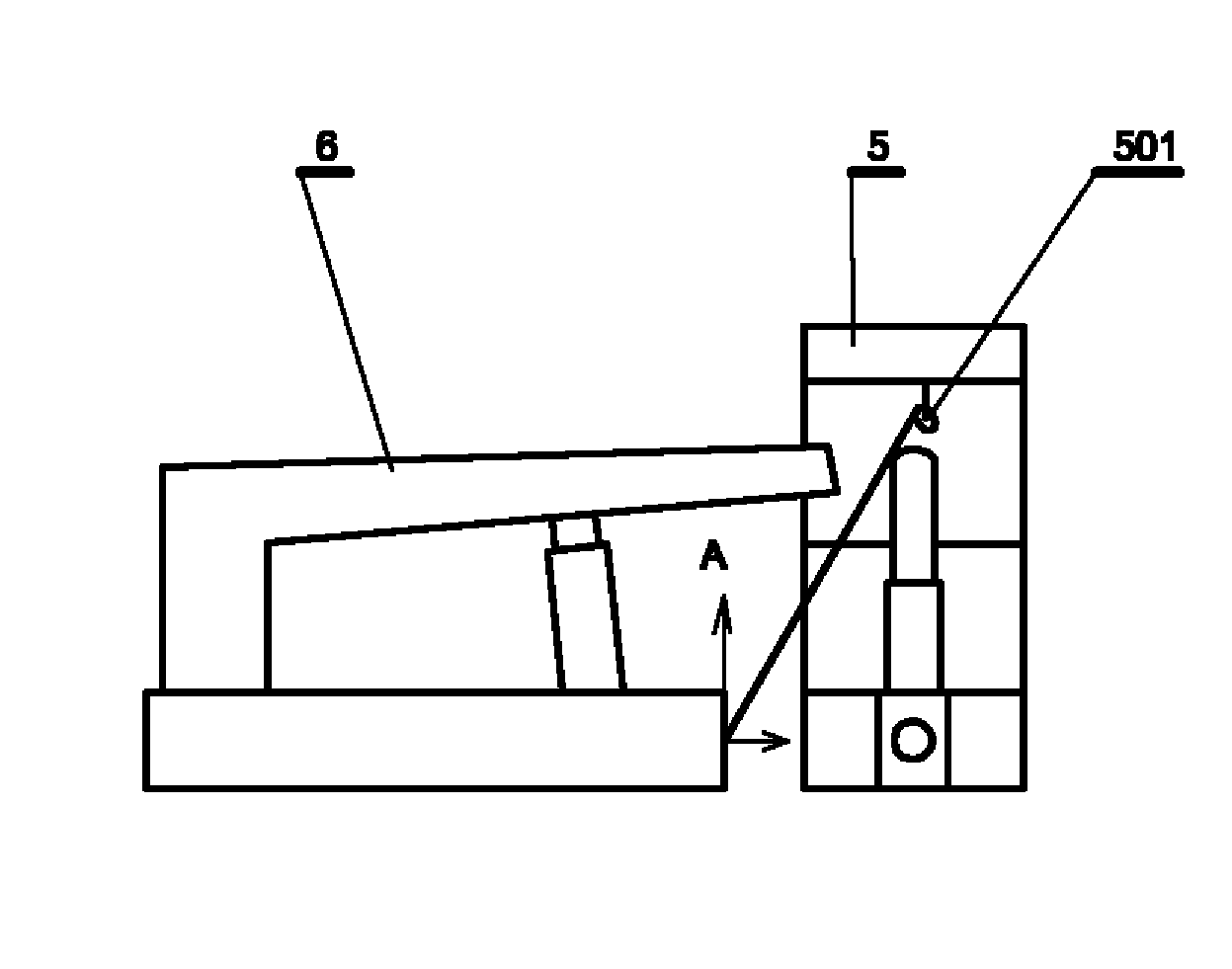

[0048] This embodiment is the key tool traction tensioner used in the method described in embodiment one, as Figure 5 shown. This embodiment includes: a beam 1101 fixed with a traction pulley, the middle part of the beam has a connecting beam 1102 perpendicular to the beam and fixedly connected with the beam, the other end of the connecting beam is fixedly connected with a short beam 1104, the The short beam is parallel to the cross beam, and forms a gate shape with the cross beam and the connecting beam. The width of the opening of the gate shape is consistent with the base of the hydraulic support. There is a pin hole 1103 at the corresponding position of the pin hole.

[0049] Such as Figure 6 Forces on the traction pulley shown. The figure shows that the traction pulley is subjected to large loads in two directions: the directions of arrows B and C. It can be concluded from the force situation that the traction pulley cannot be directly installed on the head of the c...

Embodiment 3

[0052] This embodiment is an improvement of the second embodiment, and is a refinement of the second embodiment about the tensioner. A reinforcing rib 1105 is provided between the beam and the connecting beam described in this embodiment.

[0053] In this embodiment, triangular reinforcing ribs are arranged on the beams and connecting beams according to the stress situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com