Toner deterioration judging method, image forming apparatus and developing apparatus

A developing device and degradation judgment technology, which is applied in the fields of toner deterioration judgment, developing device and image forming device, can solve problems such as increased blur, discarding, and delayed waste toner time, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described below with reference to the drawings.

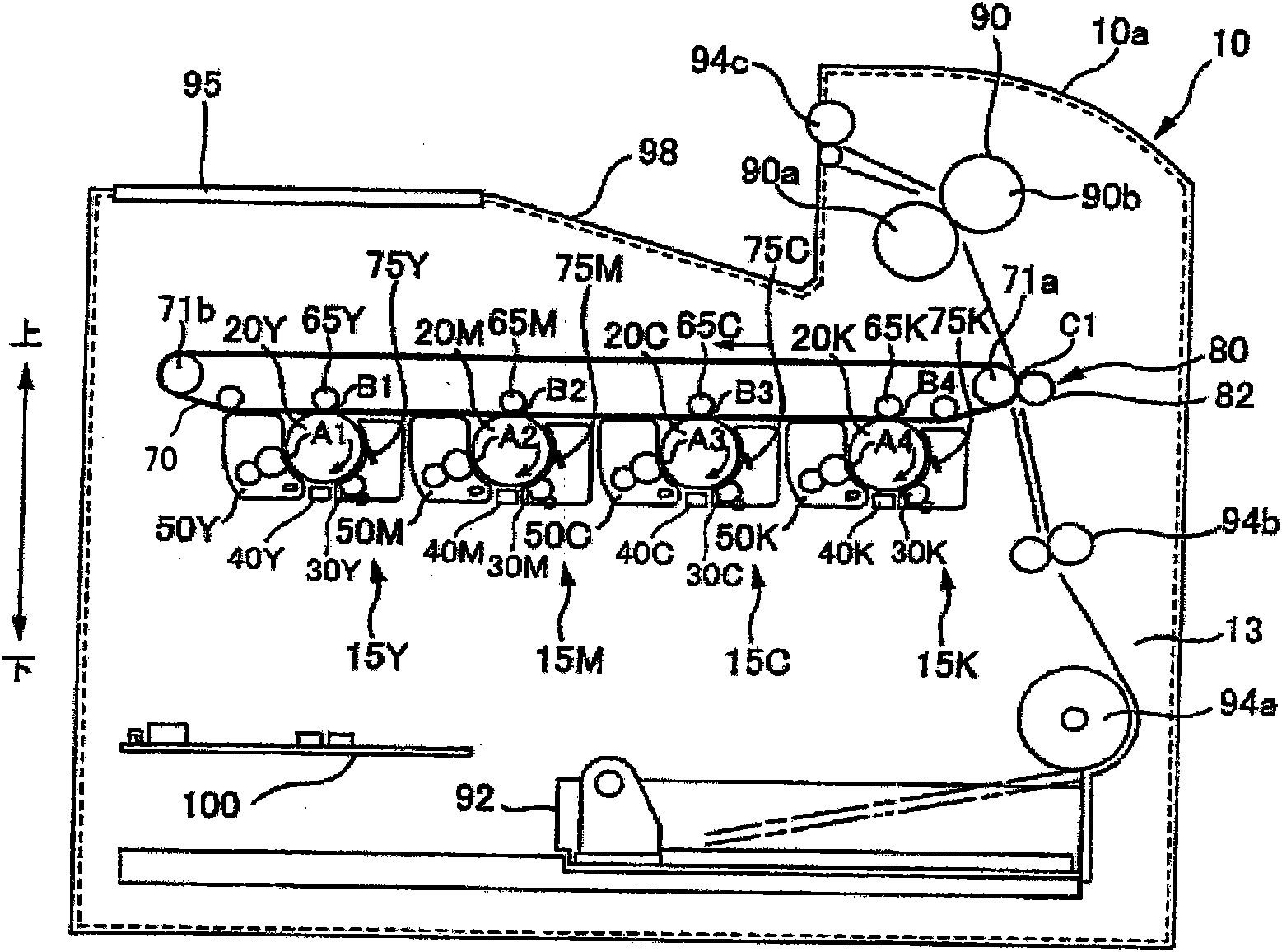

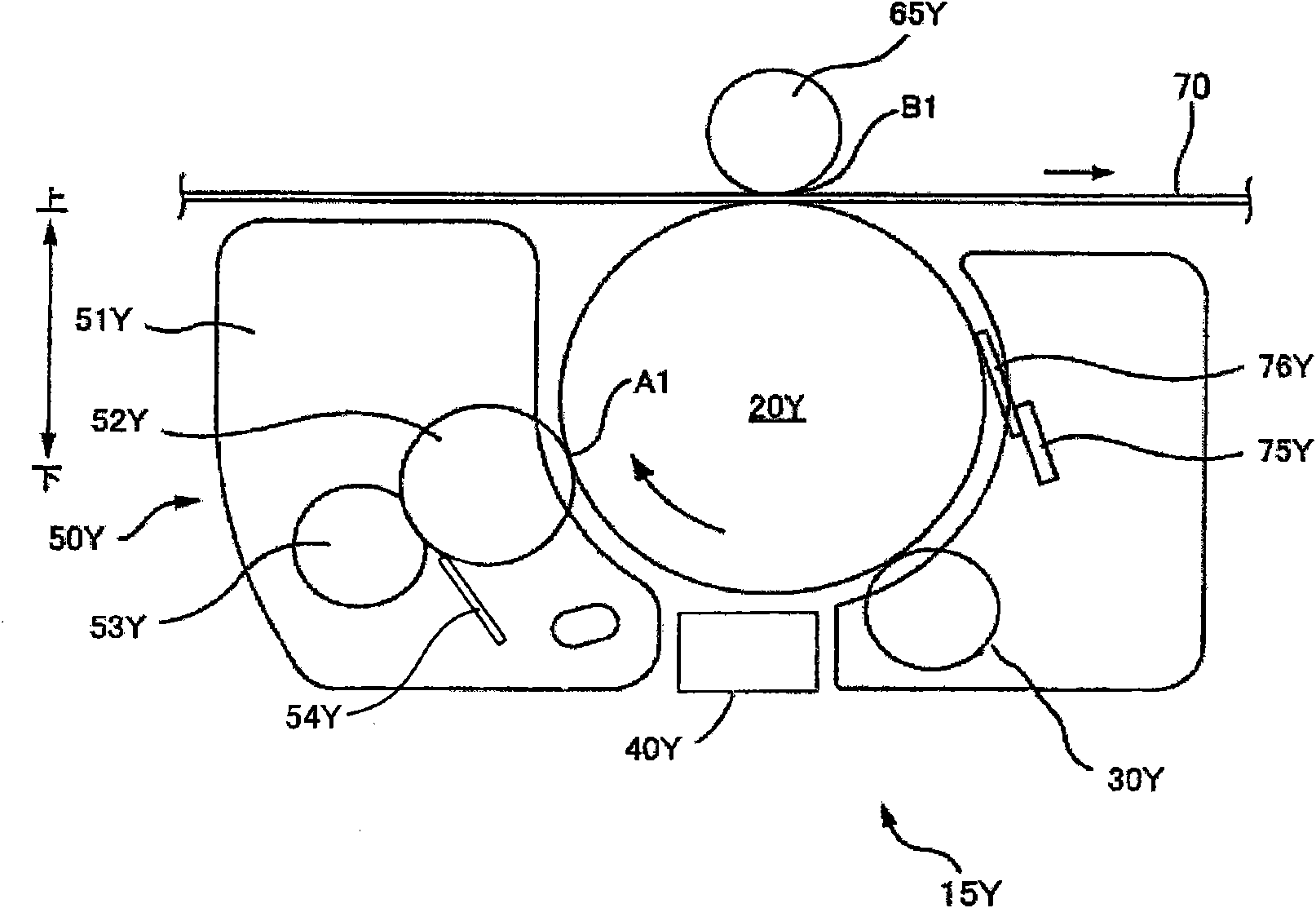

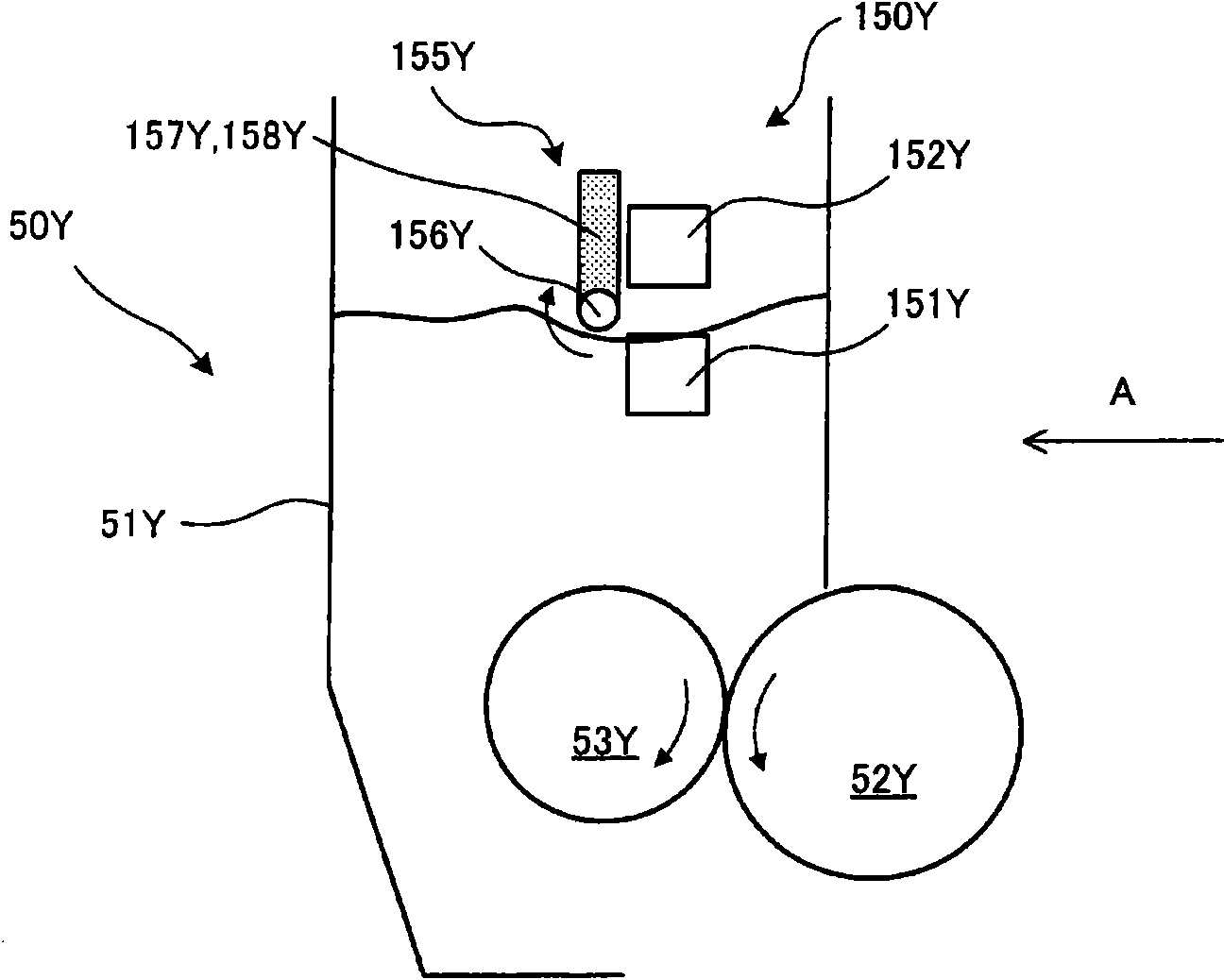

[0032] figure 1 It is a figure which shows the embodiment of the image forming apparatus provided with the developing device of this invention, figure 2 will be figure 1 A zoomed-in view of the yellow image forming station.

[0033] Such as figure 1 As shown, the image forming apparatus 10 has four image forming stations 15 (Y, M, C, K), an intermediate transfer belt 70, a secondary transfer unit 80, a fixing unit 90, a notification unit for the user and A display unit 95 constituted by a liquid crystal panel, and a control unit 100 serving as a control unit, wherein the control unit 100 controls the above-mentioned units and manages the operation of the image forming apparatus.

[0034] The image forming stations 15 (Y, M, C, K) each have a function of forming images from yellow (Y), magenta (M), cyan (C), and black (K) toners. The image forming stations 15 (Y, M, C, K)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com