Device and method for detecting the flow state of molten steel in crystallizer

A flow state and detection device technology, which is applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as complexity, unstable liquid level, and difficult detection of flow direction, so as to reduce pouring The effect of steel breakout accidents, surface quality improvement, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

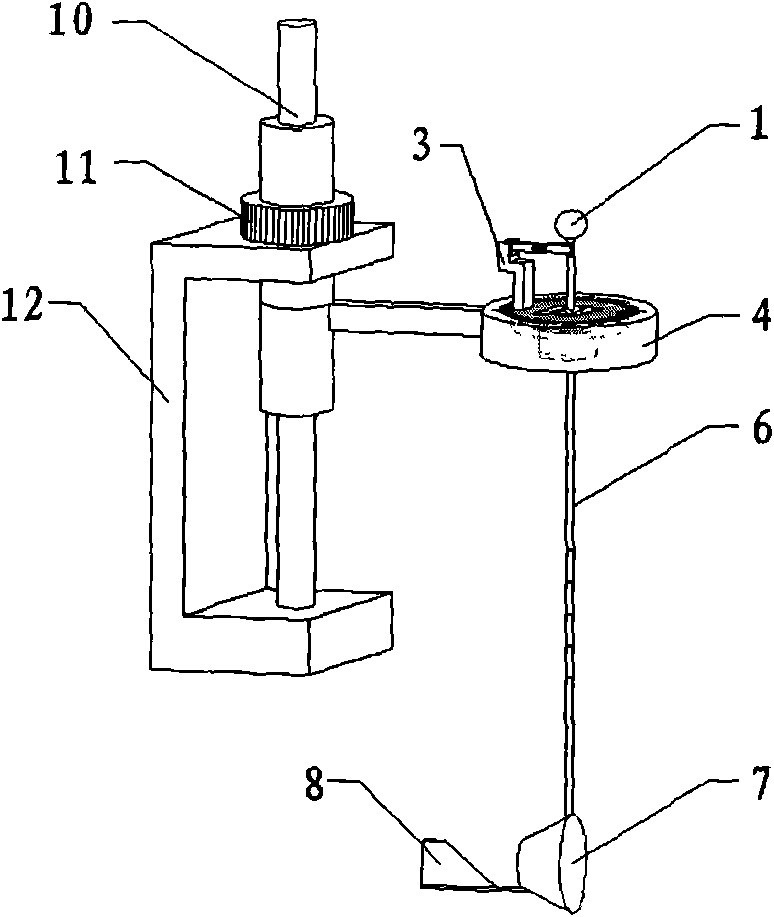

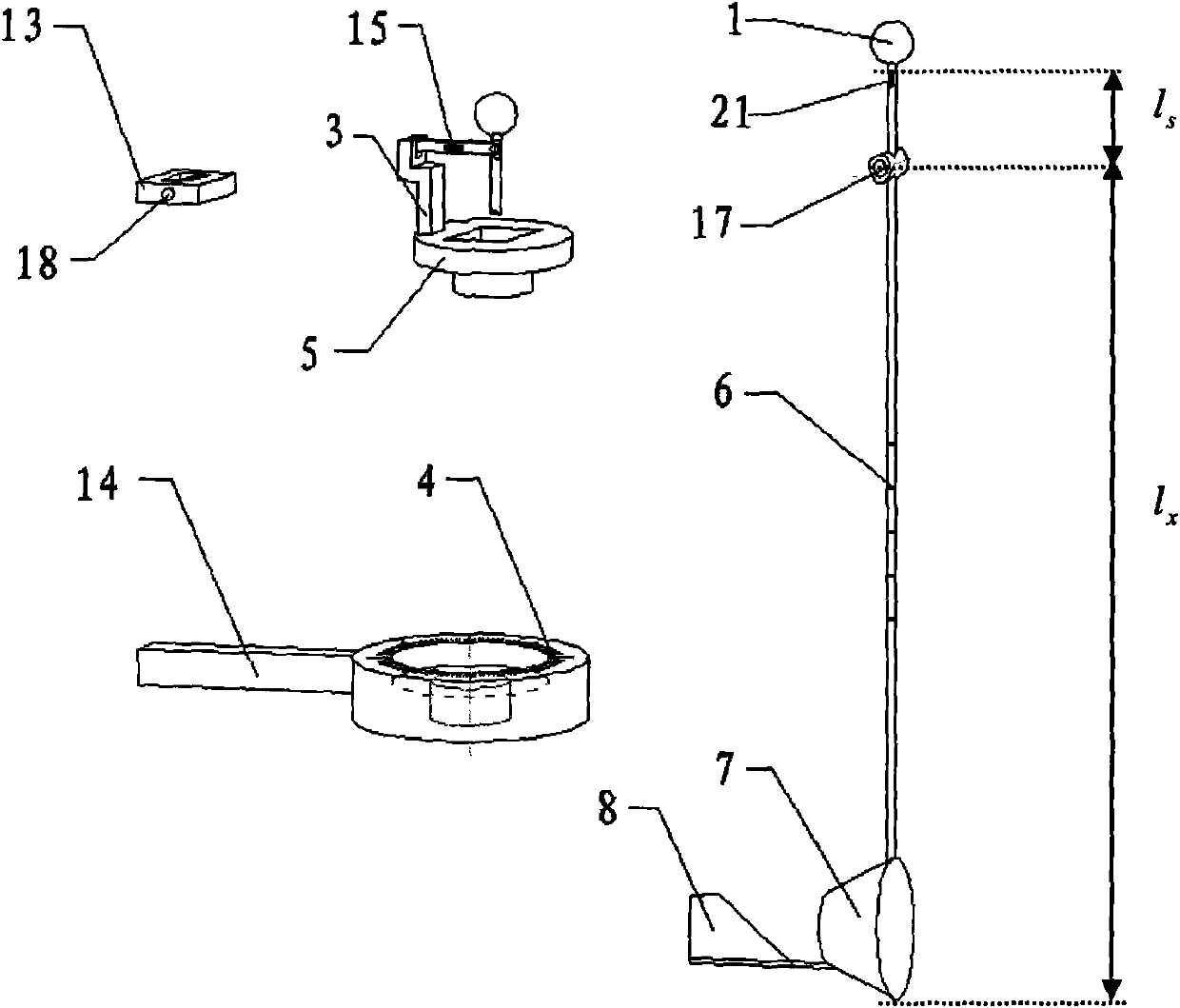

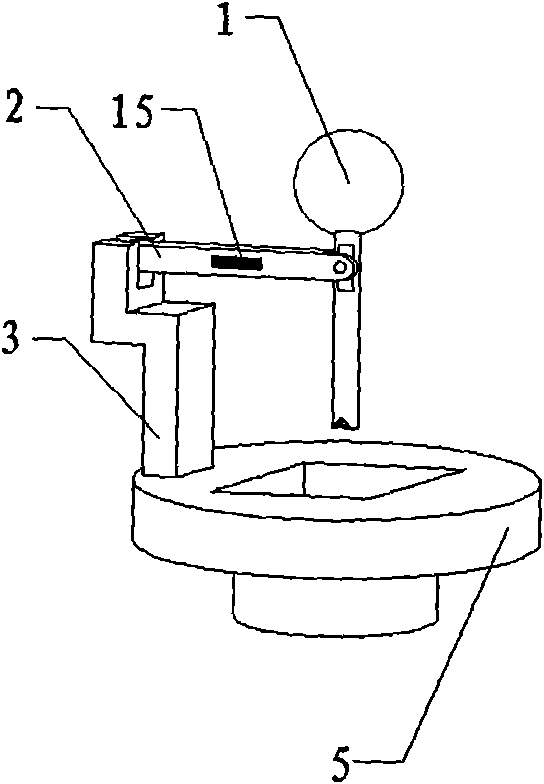

[0049]The detection device for the flow state of molten steel in the crystallizer of the present invention will be further described below in conjunction with the accompanying drawings.

[0050] First, the funnel 7 and the tail fin 8 are immersed in the molten steel 20 of the crystallizer. With the stable flow state of the molten steel 20, the molten steel 20 drives the tail fin 8, thereby driving the rotation indicating plate 5 to rotate at a certain angle relative to the tray 4. And after keeping it stable, the relative angle value indicated by rotating the indicator plate 5 is the flow direction of the molten steel 20 at the current detection point; at the same time, when the molten steel 20 flows through the funnel 7, because the funnel has a large mouth and a small mouth. Its flow resistance value pulls the pull rod 2 through the transfer action of the indicator rod 6, and the stress strain gauge 15 is pasted on the pull rod 2. When the pull rod 2 is pulled, the resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com