A load restraint assembly

A technology of assembly and locking components, applied in the direction of load fixing, reel unit transportation, vehicles for freight, etc., can solve the problem that the pallet cannot be used, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

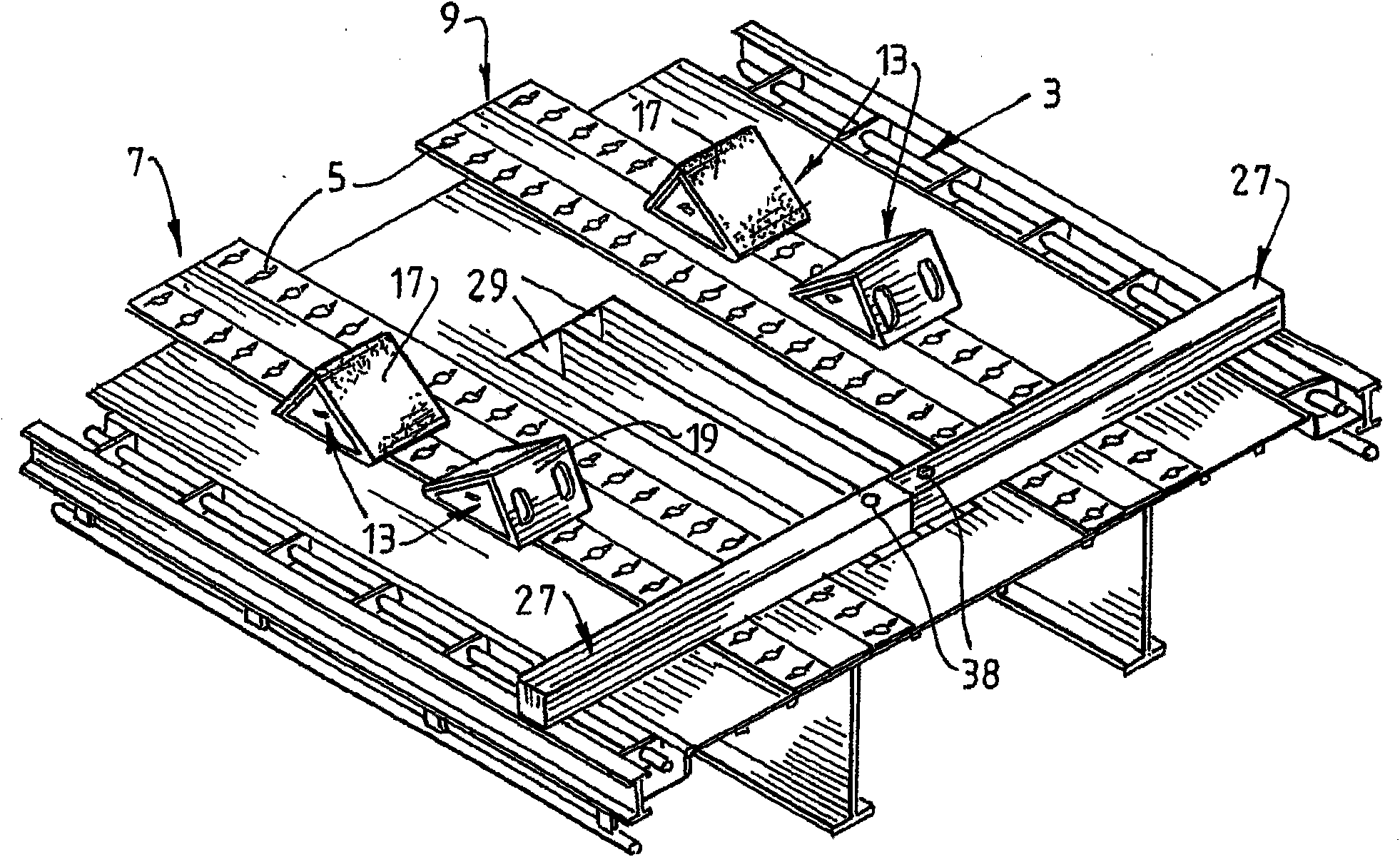

[0057] The following description is used in the context of a pallet of a truck carrying a load in the form of coiled steel strip, where the coil is placed sideways (i.e., on the outer circumference of the coil) on the pallet so that the centerline of rotation of the coil is vertical in the length direction of the pallet.

[0058] The following description is also used in the context of pallets for trucks and also carrying long loads on pallets such as bundles of steel bars, steel plates, channels and steel pipes.

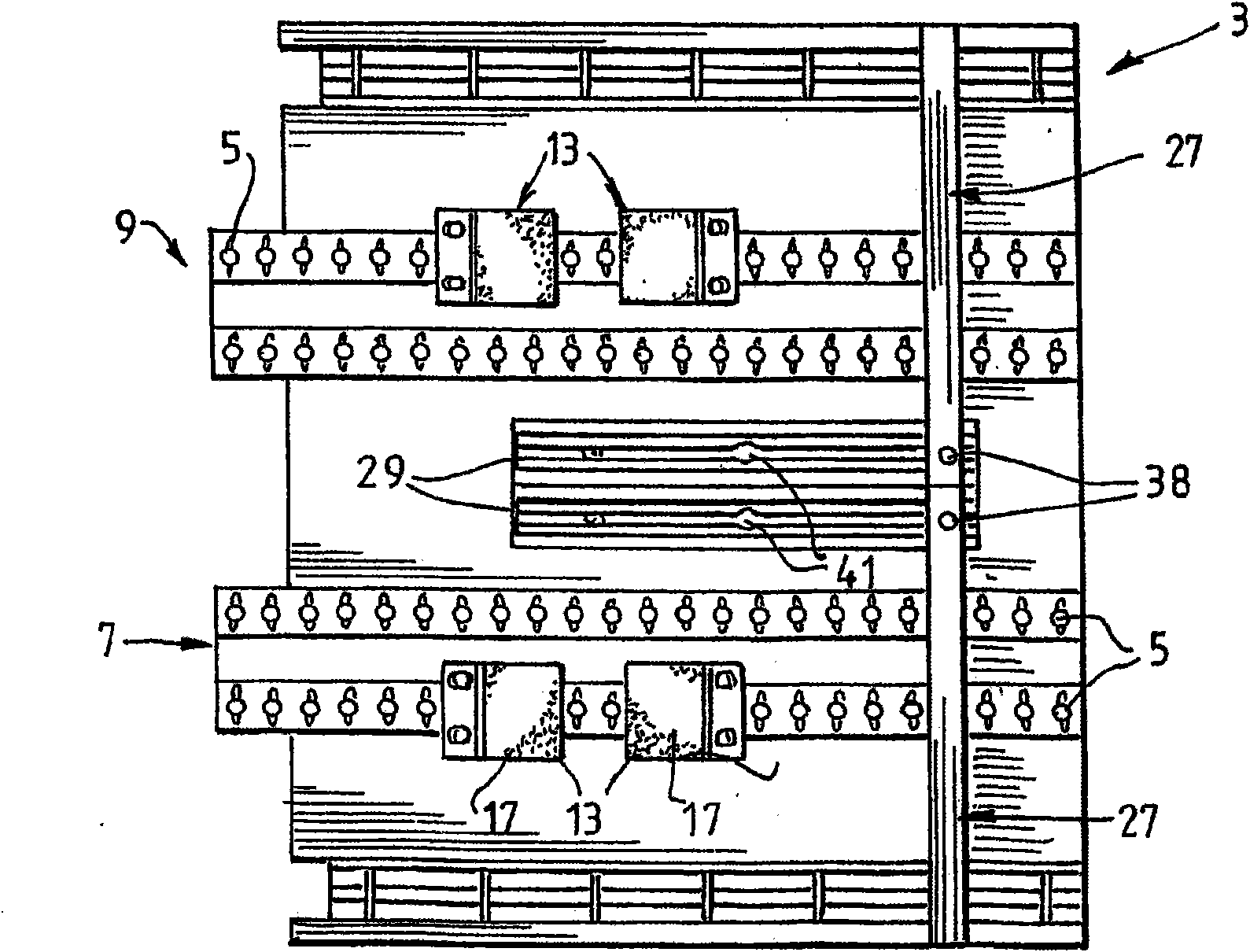

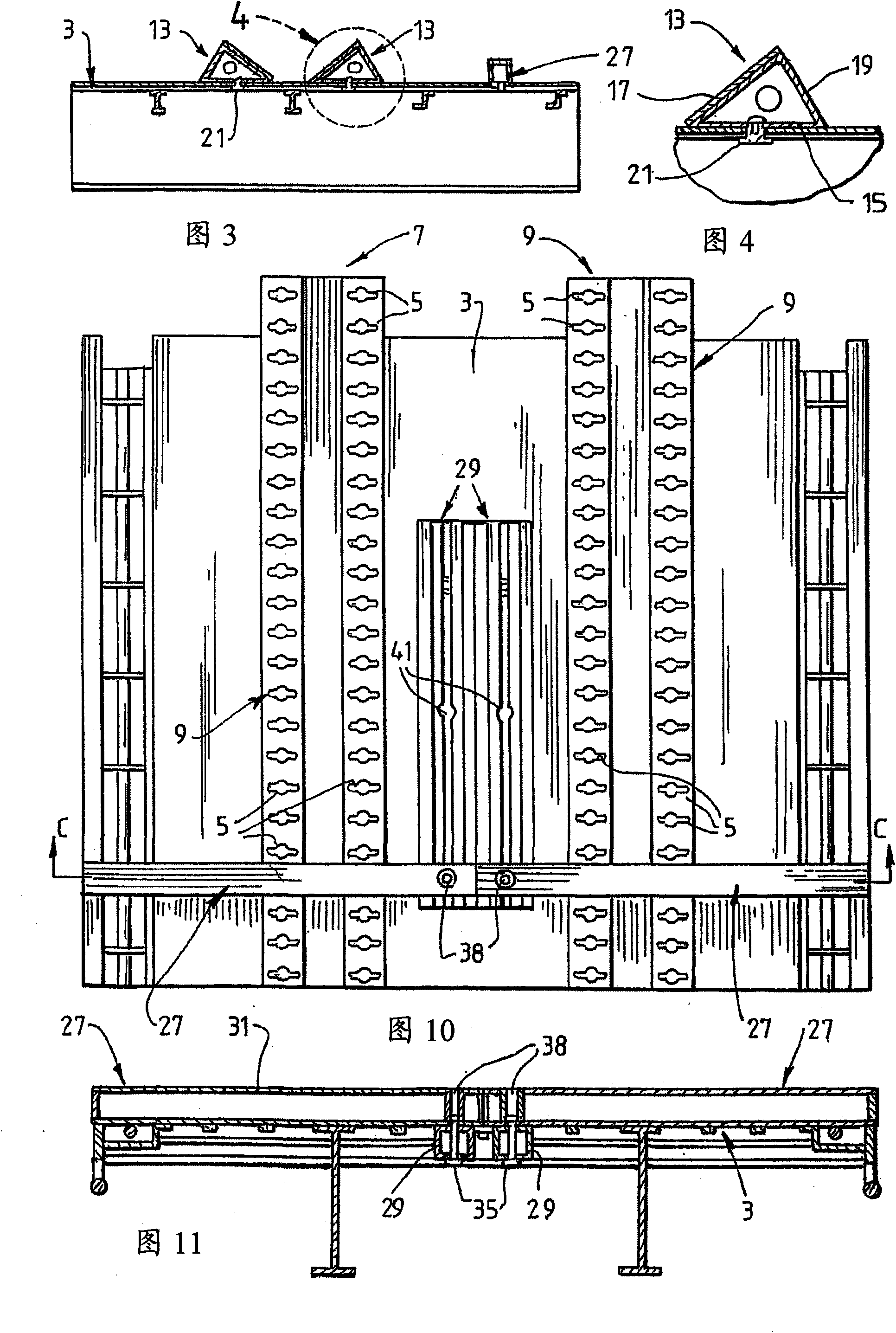

[0059] figure 1 The tray 3 shown in has 4 parallel rows of openings cut in the tray in the form of keyholes 5 . The keyholes 5 in each row have a constant interval. Typically, the center-to-center spacing of the keyholes is 100 cm. The choice of spacing is entirely a function of the load carried on the pallet. This interval is not necessarily constant.

[0060] The keyholes 5 of each row are arranged in two pairs of keyhole rows. The keyhole rows in each pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com