Automotive steering support front bracket mounting structure

A technology for mounting structures, front brackets, used in motor vehicles, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

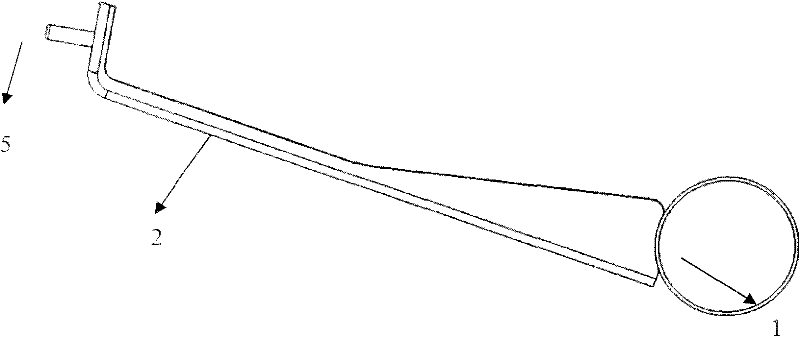

[0020] see figure 1 , the front bracket 2 of the automobile steering support is a long strip structure with stamping and flanging. 1 Solder connection.

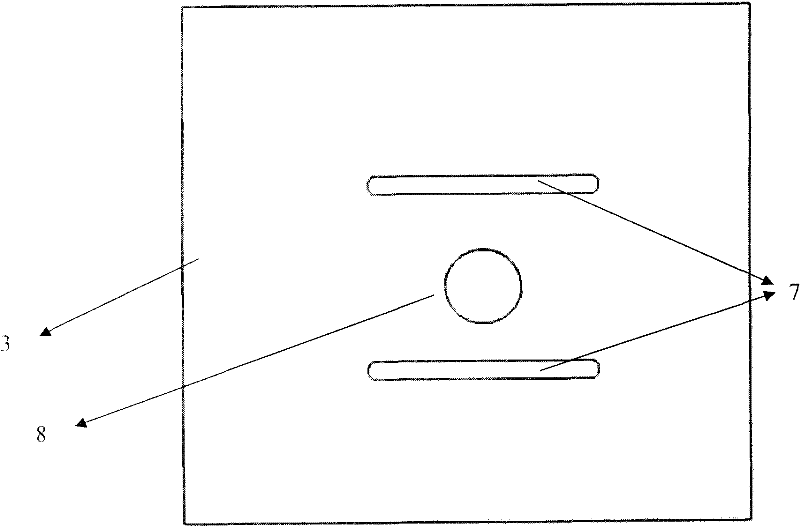

[0021] see figure 2 , the hole connected to the front bracket 2 on the front wall plate 3 is designed as a big round hole 8 much larger than the welding stud, and two parallel bar-shaped slots 7 are set above and below the big round hole 8 .

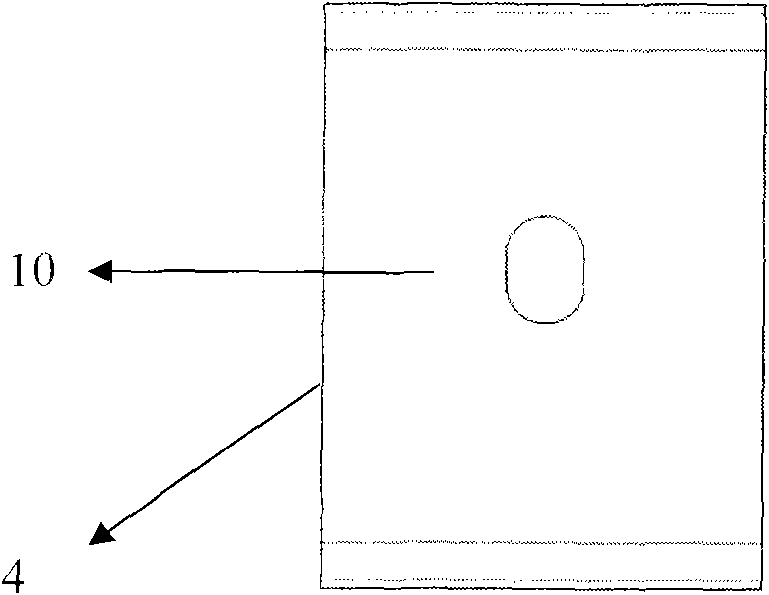

[0022] see image 3 with Figure 4 , the adjustment plate 4 is stamped and formed with a structure with flanges 9 up and down, a vertical elongated hole 10 is arranged in the middle of the adjustment plate 4, and the width of the elongated hole 10 is just to allow the welding stud 5 to pass through limit.

[0023] see Figure 5 , when assembling, put the steering support and instrument panel assembly assembled on the sub-assembly line into the body-in-white, align the positioning pins at the left and right ends of the steering support with the positioning holes on the vehicle bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com