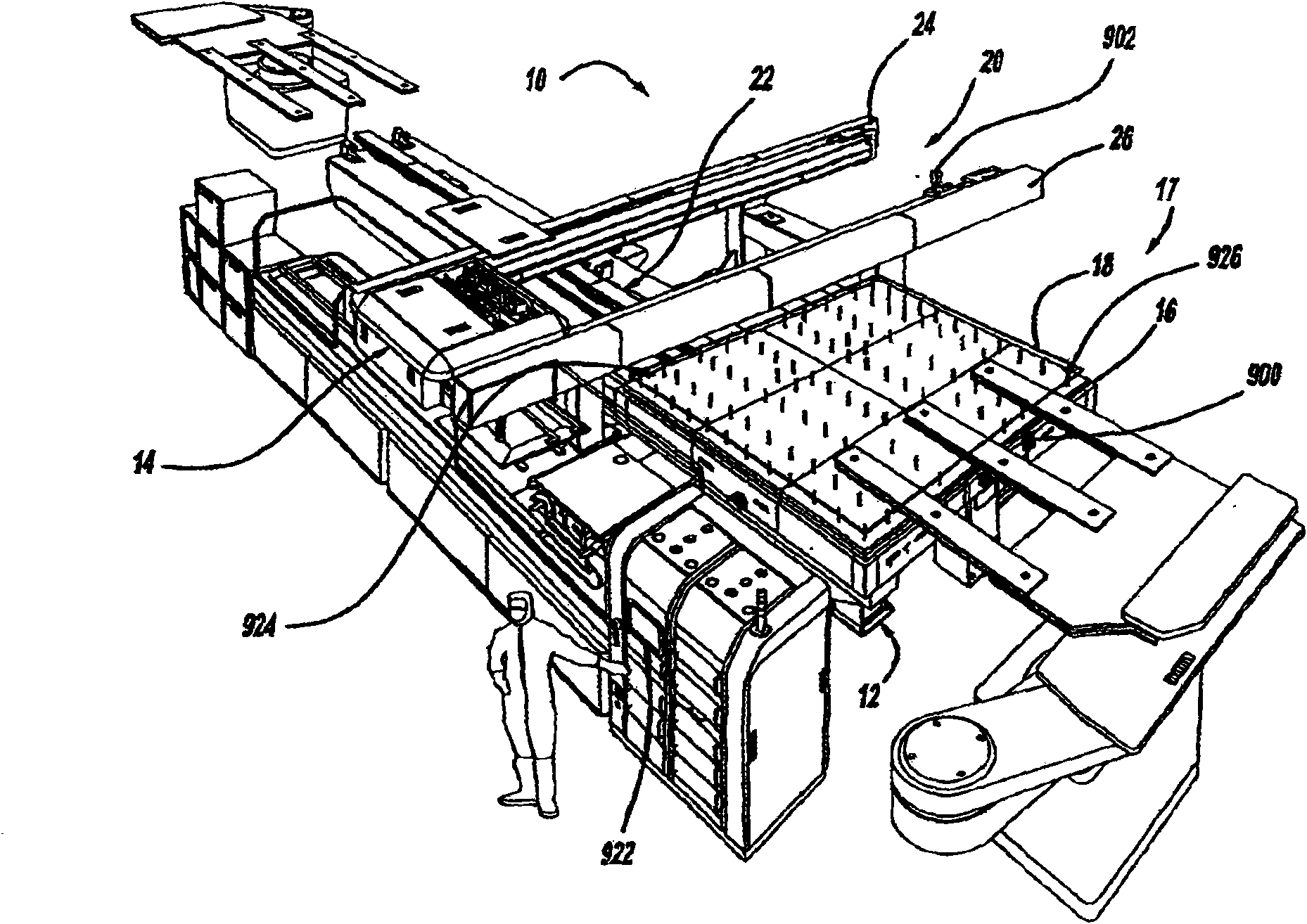

Printable substrate and nozzle alignment system

A substrate and print head technology, applied in the direction of printing, transfer materials, and character spacing mechanisms, can solve problems such as time-consuming, expensive, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following description is only an exemplary description in nature, and is not intended to limit the disclosure, application or use of the present invention.

[0048] The terms "fluid manufacturing material" and "fluid material" as defined herein may be broadly construed to include materials capable of taking on a form of low viscosity and suitable for being deposited (e.g. from A PDM head deposits onto a substrate to form a microstructure). Fluid fabrication materials may include, but are not limited to, Light Emitting Polymers (LEPs) that may be used to form Polymer Light Emitting Diode display devices (PLED, PolyLED). Fluid fabrication materials can also include plastics, metals, waxes, solders, solder pastes, biomedical products, acids, photoresists, solvents, adhesives and epoxies. The term "fluid manufacturing material" is interchangeably referred to herein as "fluid substance".

[0049] The term "deposition" as defined herein generally refers to the process b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com