Clamping device having mechanical damping for a traction engine drive

A technology of tensioning device and transmission device, which is applied in the direction of transmission device, mechanical equipment, belt/chain/gear, etc., and can solve the problem of increasing the edge load of the sliding support part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

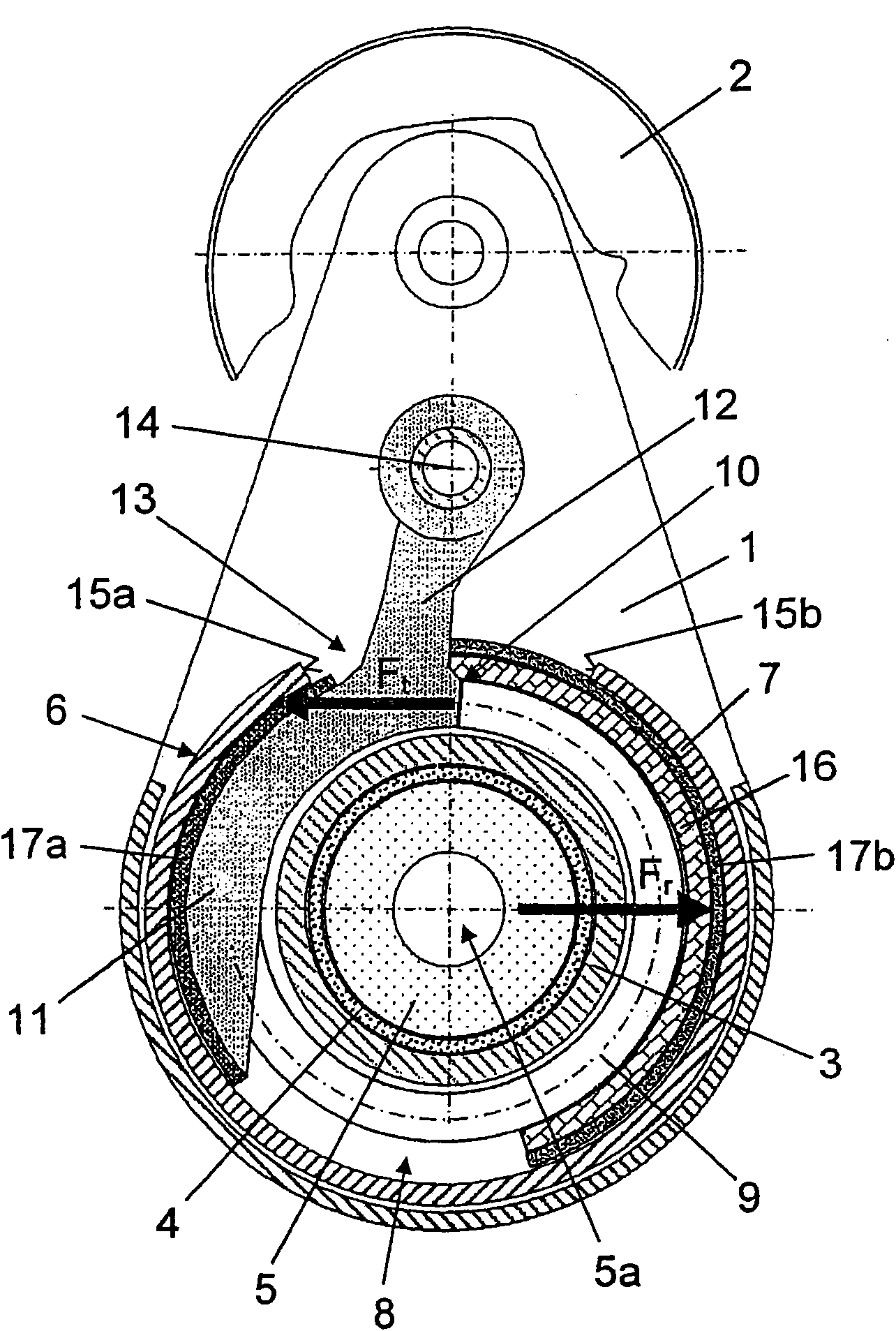

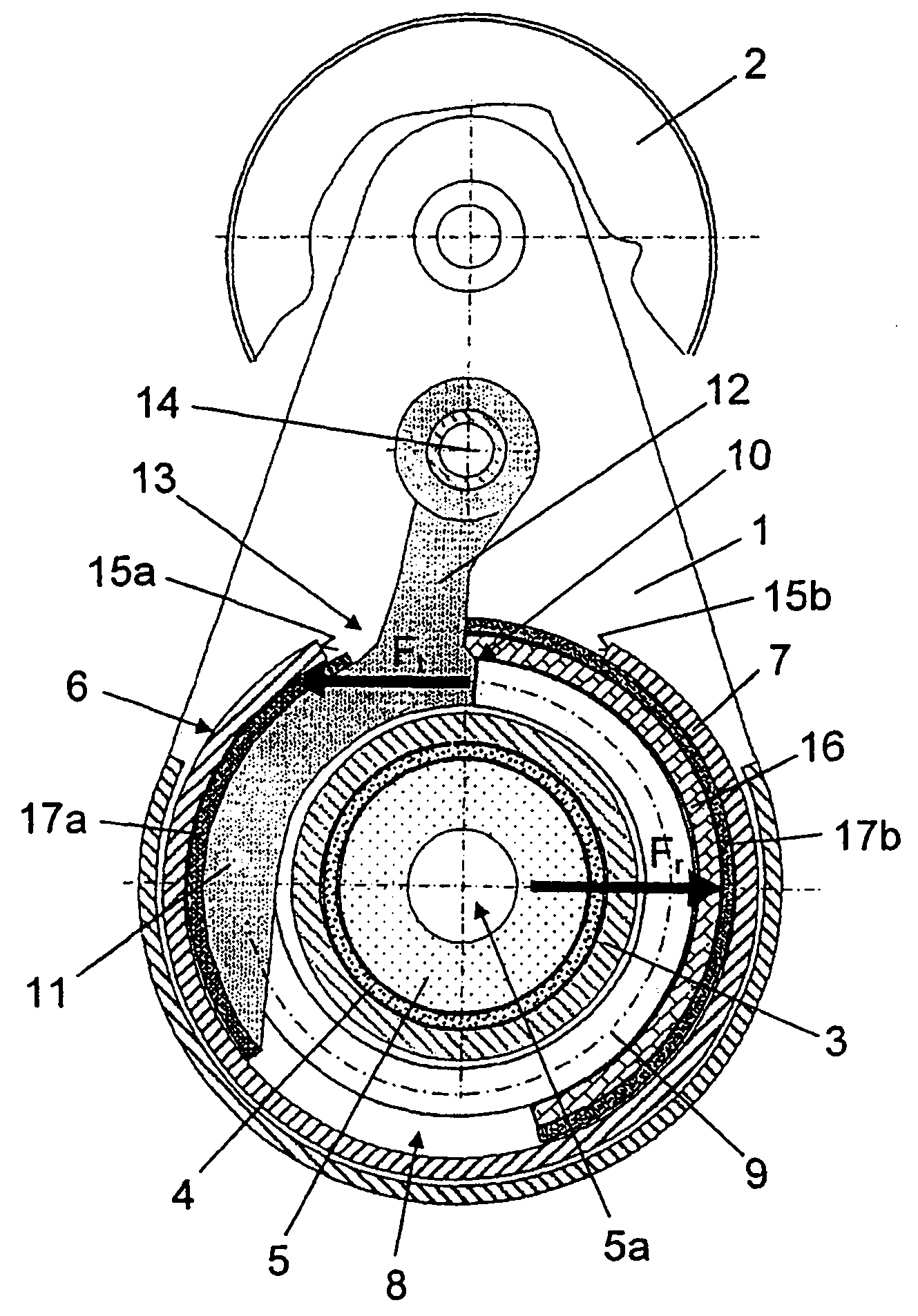

[0020] The tensioning device for the traction mechanism drive (not shown in detail) has a known tensioning roller support 1 constructed in the manner of a single-arm lever, which supports a tensioning roller 2 at its free end. The other end of the tensioning roller bracket 1 is rotatably supported by means of a hub-shaped bearing part 3 via a sliding bearing 4 in the form of a bearing sleeve on a centrally arranged bearing pin 5 of a stationary base part 6 which, for its part, is It has a bowl-shaped shape and can be fixed on a supporting component, which can be a motor housing or a transmission housing of a motor vehicle, by means of mechanical fixing elements, such as fixing bolts (which pass through the axial holes 5a of the support bolt 5) body.

[0021] In the annular space 8 formed between the inner contour of the wall 7 of the pot-shaped basic part 6 and the hub-shaped support part 3 of the tensioning roller bracket 1, a torsion spring 9 is arranged concentrically surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com