Falling protection device of hoisting mechanism

A technology of fall protection and fixing devices, which is applied in elevators, transportation and packaging, etc. It can solve the problems of excessive falling braking distance, reduced action sensitivity, and affecting the structural safety of the lifting mechanism, etc., and achieves the effect of safe locking and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

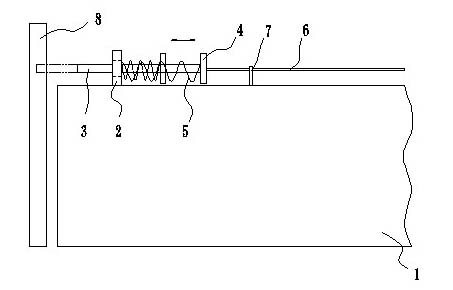

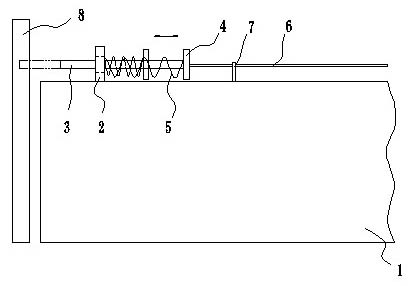

[0010] Such as figure 1 As shown, the lifting mechanism fall protection device of the present invention includes a fixing device 2 vertically fixed on the base 1 of the lifting mechanism, a safety push rod 3 passing through the guide hole of the fixing device 2 horizontally, and fixed on the safety push rod 3 The limit ring 4 at the right end of the push rod 3 is set between the fixing device 2 and the limit ring 4 and is set on the extension spring 5 on the safety push rod 3 with a gap; the traction cable 6 passes horizontally through the set The limiting device 7 on the right side of the limiting ring 4 is fixedly connected with the limiting ring 4 . A limit switch for detecting the limit position of the safety push rod 3 is also arranged on the limit ring 4, and the limit switch is electrically interlocked with the electric control system of the lifting mechanism. In the traction state of the traction cable 6, the traction force is greater than the tension of the extension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com