A flushing device in machines for manufacturing single pouches of cohesionless material and in systems for portioning and packaging tobacco molasses

A non-cohesive, equipment technology, used in the field of flushing equipment, can solve problems such as reducing machine and system output capacity maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

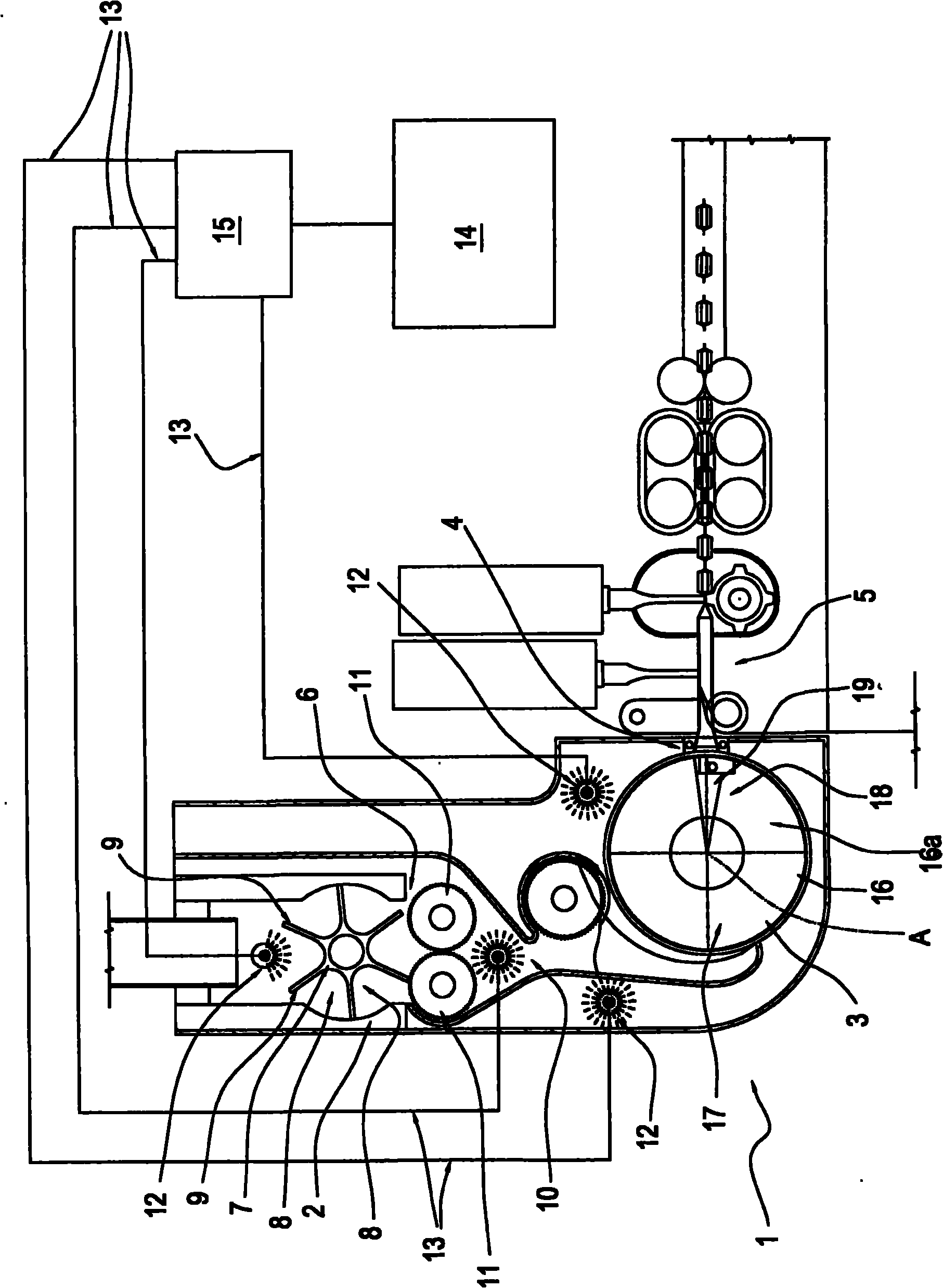

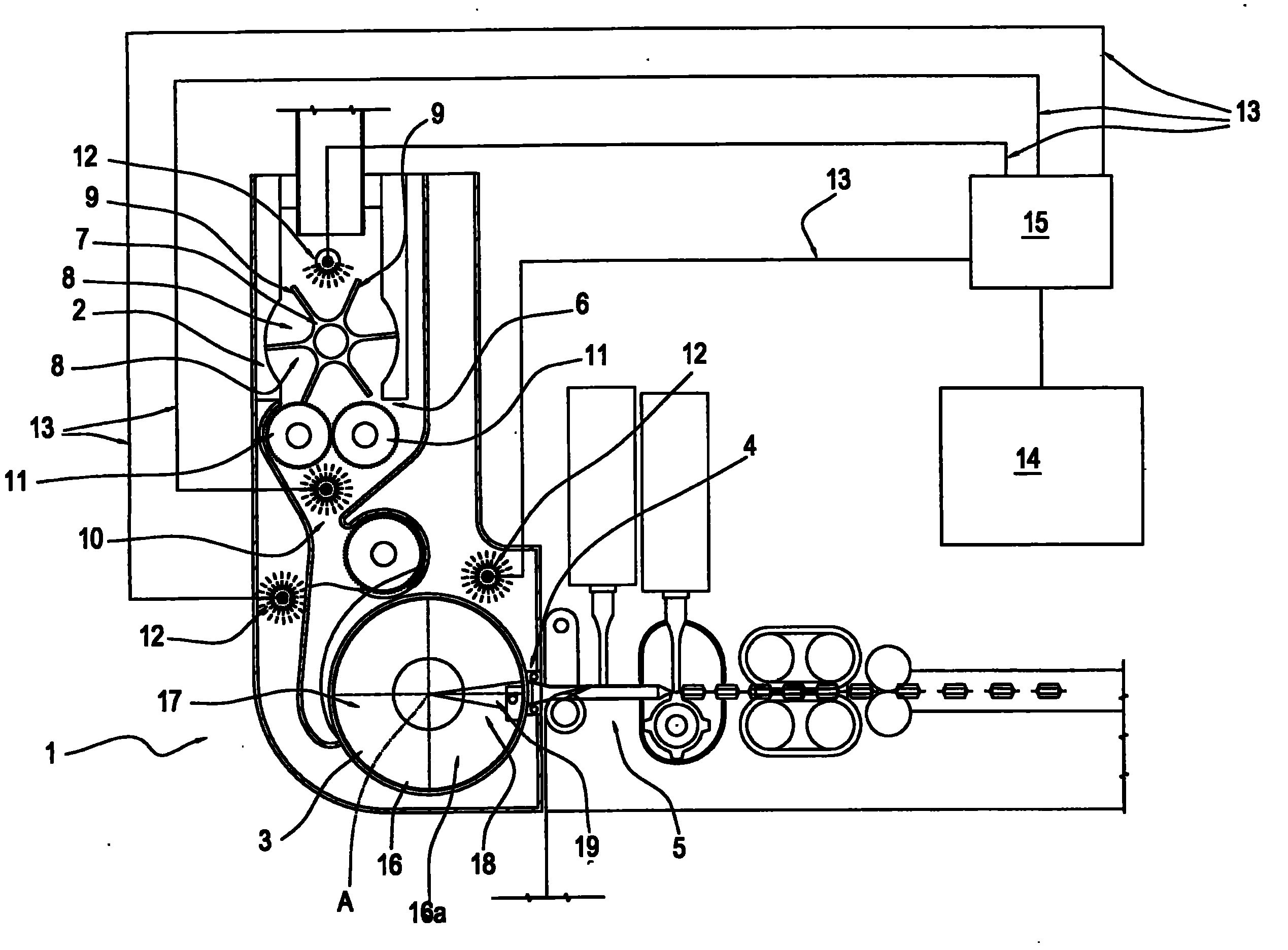

[0013] see figure 1 , reference numeral 1 designates a machine for manufacturing sachets 2 comprising non-cohesive material.

[0014] The machine 1 comprises an output station 2 at which the non-cohesive material is released to a conveyor 3 which is rotatable between the output station 2 and a transfer station 4 where it is ejected Successive tobacco sections.

[0015] The machine 1 also includes a packing station 5, the full description of which is disclosed in the applicant's Italian patent application n° BO2006A 000792, filed on November 22, 2006, where the tobacco fraction ejected from the transfer station is received and seal it in the corresponding pouch.

[0016] The output station 2 comprises a take-up, preliminary treatment and feeding unit 6 by which the non-cohesive material is received from a hopper (not shown) and released to the above-mentioned conveyor 3 .

[0017] The collection unit 6 comprises a distribution wheel 7 having pockets 8 delimited by radial bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com