Multidimensional automatic metal heat spray-painting device

A spraying device, metal heat technology, applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of unhealthy operators, low utilization rate of metal wire, high equipment cost, etc., and achieve stable effect and reduce Production cost, effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with specific embodiment:

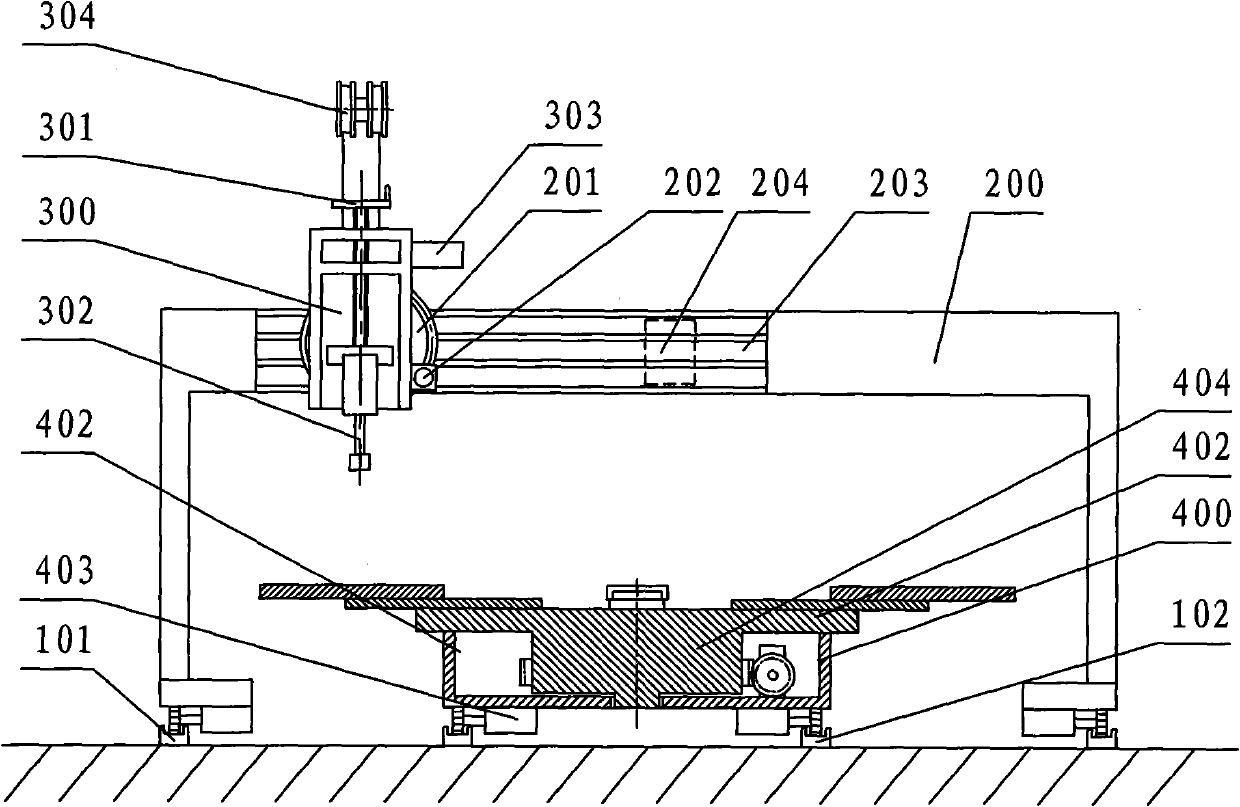

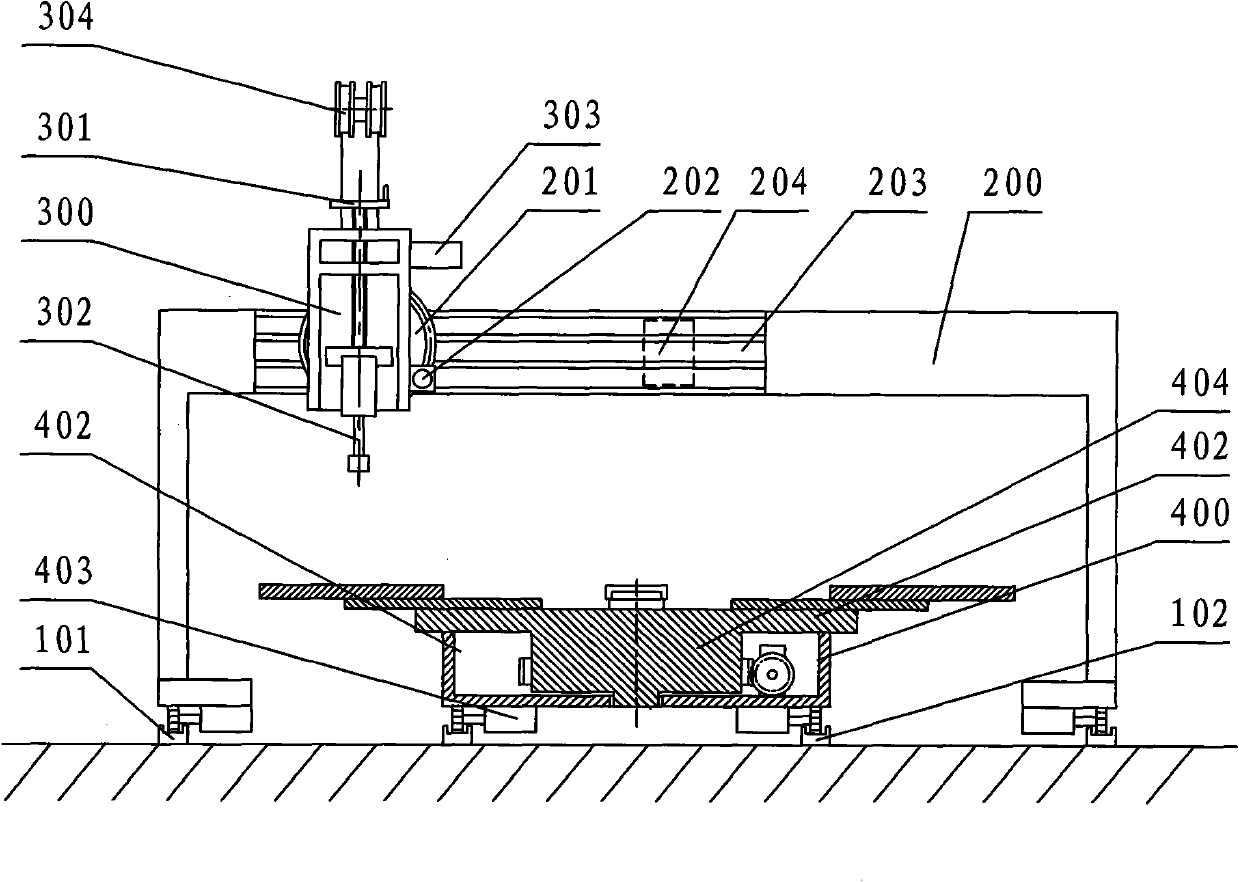

[0020] See figure 1 , which is a structural schematic diagram of the present invention, including a gantry frame 200 , a spray gun seat 300 and a workbench 400 . A spray gun 302 is arranged on the spray gun seat 300 .

[0021] The gantry 200 is arranged on the track 101 , and the gantry is provided with a motor for driving the gantry 200 to reciprocate along the track 101 .

[0022] A slide rail 102 is provided below the gantry 200 , and a workbench 400 that can reciprocate along the slide rail 102 is provided on the slide rail 102 .

[0023] The gantry 200 includes a gantry beam 203 . The gantry beam 203 is provided with a spray gun seat 300 and a transverse drive mechanism, the gantry beam 203 doubles as a transverse slide rail, and the spray gun seat 300 doubles as a transverse slide seat, which can reciprocate along the gantry beam 203 under the drive of the transverse dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com