Automatic vending machine

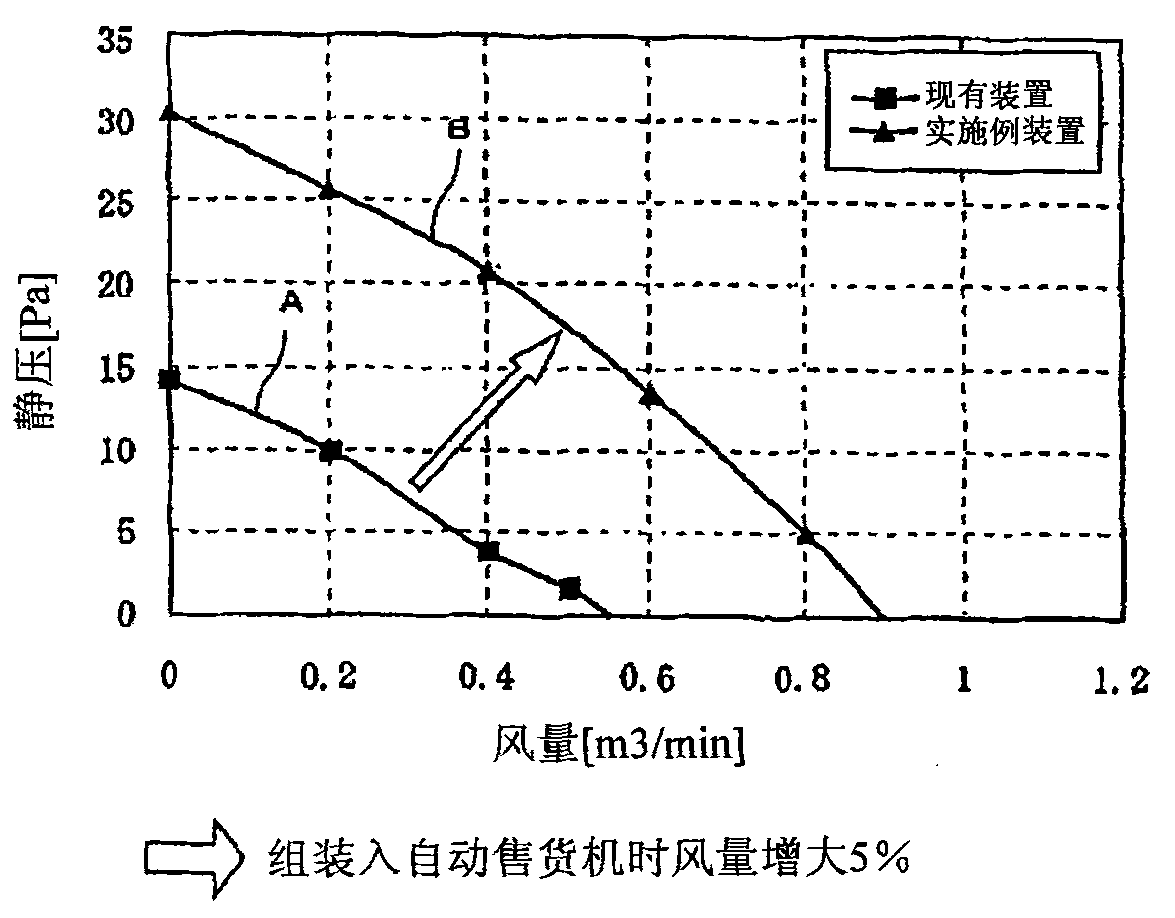

A technology for vending machines and shelves, applied in the direction of processing coins or valuable banknotes, instruments, etc., can solve the problems of increased time for commodity temperature adjustment, increased burden on air supply mechanisms, and reduced heat exchange efficiency, and achieves uniformity, Increase the pressure loss and achieve the effect of air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

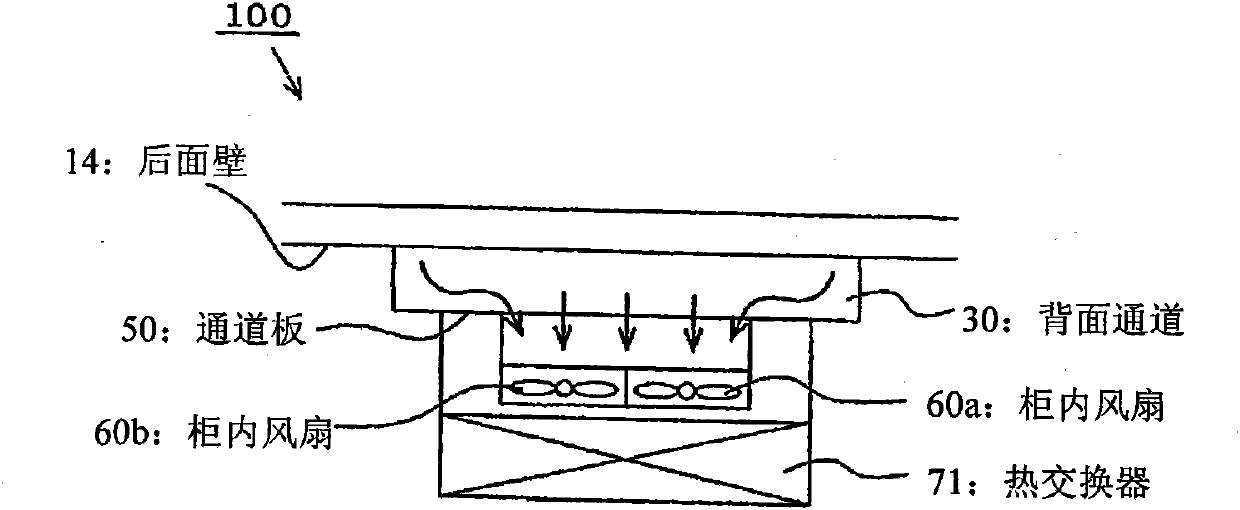

[0077] Figure 1 ~ Figure 3 is a diagram schematically illustrating an automatic vending machine according to Embodiment 1 of the present invention, figure 1 is the overall cross-sectional view viewed from the side, figure 2 It is a cross-sectional view viewed from the side in which a part is enlarged and shown, image 3 It is a plan view viewed from above in which a part is enlarged and shown.

[0078] exist Figure 1 ~ Figure 3 Among them, an automatic vending machine (hereinafter referred to as "vending machine") 1 has: a product storage cabinet 10 composed of a box surrounded by a heat insulating material; The product shelf 20 of the function of the product; the product export port 12 formed on the front wall 11 of the product storage cabinet 10 and capable of freely passing the product; the slideway ( Equivalent to commodity guidance mechanism) 13.

[0079] Below the slideway 13, a heat exchanger 71 and an in-cabinet heater 72 that adjust the temperature of the air ...

Embodiment approach 2

[0087] Figure 4 ~ Figure 6 is a diagram schematically illustrating an automatic vending machine according to Embodiment 2 of the present invention, Figure 4 is a perspective view representing the channel plate, Figure 5 are plan-viewed and side-viewed cross-sectional views representing the channel plate, Figure 6 It is a perspective view showing the channel plate on which the fan case is attached.

[0088] exist Figure 4 ~ Figure 6 Among them, the back channel rectification mechanism 200 of the automatic vending machine (not shown) of Embodiment 2 includes: a channel plate 54 formed with suction ports 51a, 51b for air inflow at the upper part; The channel auxiliary plate 55 of the opening part (not shown). Furthermore, the fan case 61 is provided on the tunnel plate 54 via the tunnel auxiliary plate 55 .

[0089] A plurality of rectifying plates 52a, 52b, 52c, 52d, and 52e protruding toward the cabinet fans 60a, 60b are formed on the channel auxiliary plate 55 . And...

Embodiment approach 3

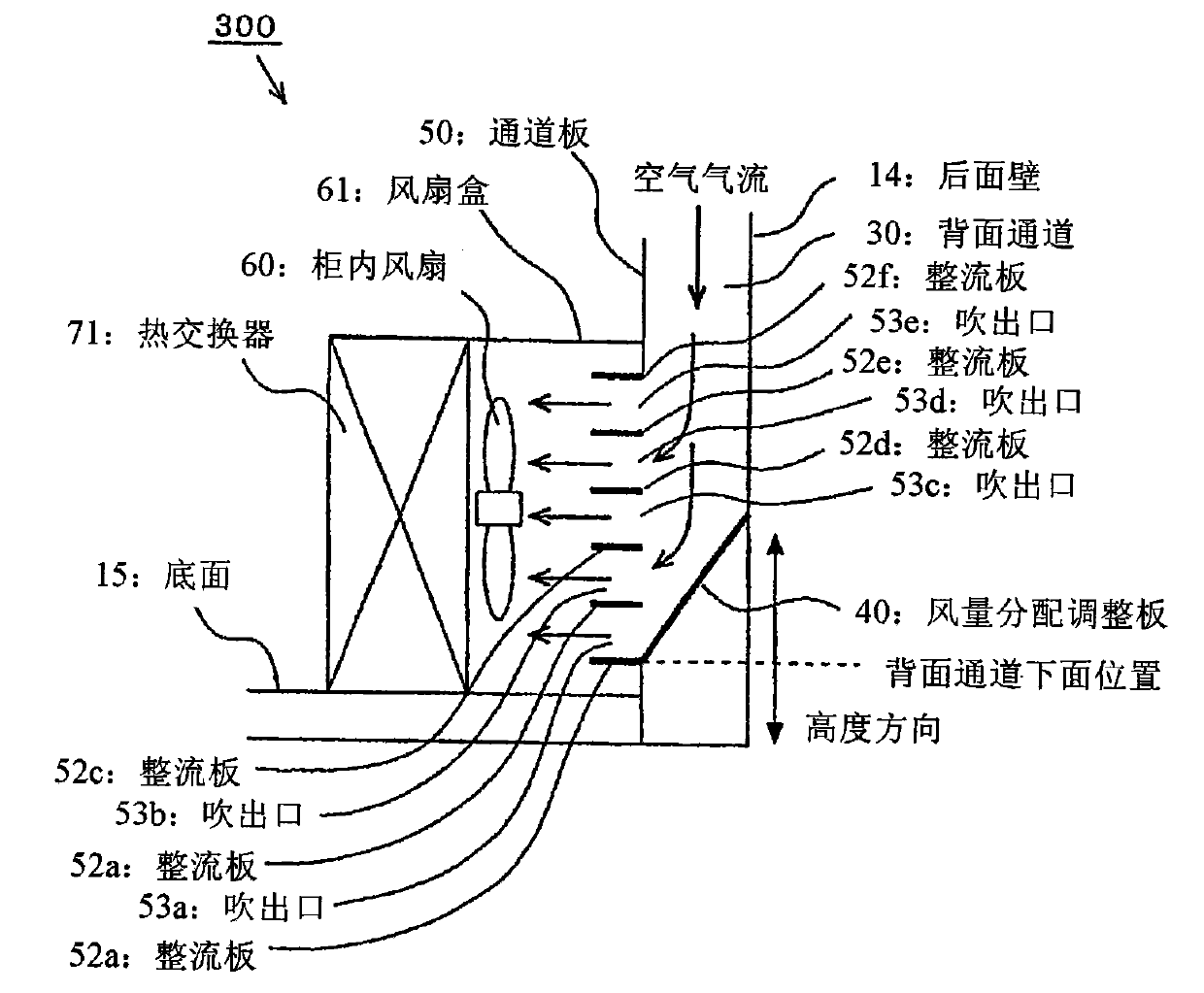

[0093] Figure 7 It is a figure schematically explaining the automatic vending machine which concerns on Embodiment 3 of this invention, and is a cross-sectional view seen from the side which enlarged and showed a part.

[0094] exist Figure 7 Among them, the rear passage straightening mechanism 300 of the automatic vending machine (not shown) of Embodiment 3 is similar to the rear passage 30 of the rear passage rectification mechanism 100 (Embodiment 1), and the air volume distribution adjustment plate 40 is provided at the lower part. Therefore, the same reference numerals are assigned to the same or equivalent parts as those in Embodiment 1, and a part of description thereof will be omitted. Also, for common content, the suffixes "a, b, c, d, e, f" are omitted.

[0095] The air volume distribution adjustment plate 40 is provided across the rear side edges of the rear wall 14 and the adjustment plate 52a (formed at the lowermost). The air volume distribution adjusting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com